@palo said:

Hi jo

My mission for CabinetSense is to provide an easy to use, affordable solution for the smaller cabinet firm. Sketchup is certainly both of that and only time will tell if I can deliver as well.

I hope to move CS in two directions, firstly as a design tool that will help sell as well as cement the specifications of the job; and secondly as a production tool that will accurately and seamlessly move the job to the shop floor.

Certainly as a production tool, cnc is on the radar. One of the inherent issues with Sketchup in this regard is that it represents arcs as a series of line segments. However, CabinetSense is not meant to be one-stop solution and I believe a viable solution to this is to simply defer any radius work to another program. CS would do the bulk of the case good processing including, drill points, dados... I'm still very much of a novice when it comes to cnc and the different ways you can communicate with them.... whether that be DXF or direct-to-machine coding. I have no timeframe for implementing this, but it is more of a learning exercise at this time rather than a work-in-progress.

Thanks for your input.

Paul

Hi Paul,

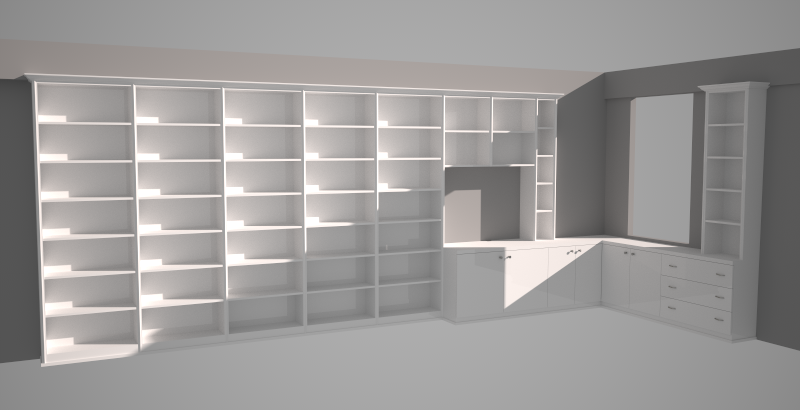

We are furniture wall units ,large bookcase manufacturer in Ny , I just found this blog when I was searching SU CNC output, I downloaded and tested your CS , it is really nice fast and very accurate, I have very similar SU dynamic component that I wrote,OC32 and merged with several softwares , It is base on 32mm european system frameless cabinetry, ( case ,door, drawer, shelve , partition and toe) after I input all the measurements I make unique of all the parts and add machining terms names each part, the longest time consuming is the preparing the part names We cut at automatic panel saw 300-400 unique parts then we drill at the automated boring machine, spray the finish and assemble every week.

some suggestions,

- drop dow menu, material thickness change all or individually

- drop down menu, change doors and drawers front, inset or outset from the carcass,

- change height of the drawer box and drawer front separately but they will be in group

- space between back of the door and carcass frame when door overlays the carcass

- aplie same principle at parent, all carcass panel can be inset or outset or one end inset other end outset ( same as the pack panel future at parent )

thanks

Ozan