As I was processing a job this morning using CabMaker and Cutmaster I couldn’t help but think about how I was using one of the best kept secret tools available to cabinetmakers. Garry has been adding features at a pace I’ve never witnessed in my 30 years of using software in my cabinet making business. What he has developed over the past few years is way too powerful of a tool to be kept secret.

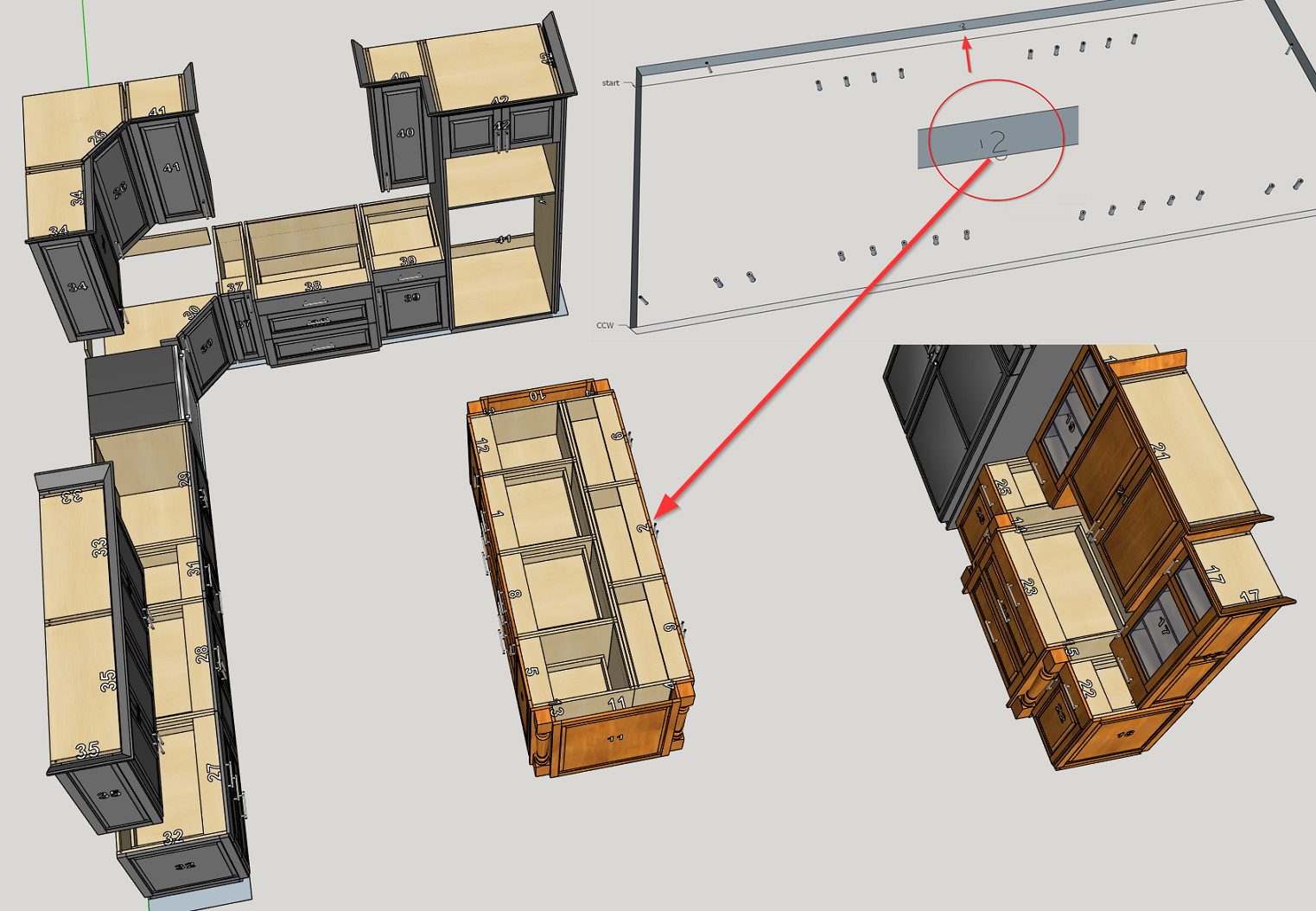

In this order I’m working on today I’ve got a kitchen with a cherry island and hutch in a kitchen where all of the other units are painted. All boxes cut out of prefinished maple plywood. Having to break this job up into two batches so that the edgebanding color is handled properly by the banding operator causes yield issues.

Creating optimized patterns and g-code for this job as single batch while handling different banding colors through notes and other manual methods for making sure the banding color per cabinet is accurate requires extra time and is error prone.

With CabMaker and Cutmaster it is easy to route the cabinet number on each part and then provide banding instructions per each part including using different symbols to denote different banding colors.

In this example you can see how the arc facing the front edge of this side panel tells the operator to band that edge with matching cherry pvc while the straight line aligned with the top edger tells the banding operator to band that edge with another color.

This is just one example of power Garry is providing with his CabMaker plugin and CutMaster program.