I recently completed a project in which Sketchup was very helpful and I thought it might be interesting to share exactly how I used it, especially for those who are new to the forum and would like to see some of what Sketchup is capable of.

I was commissioned by a customer to make a reproduction of an Oak hall tree made around 1890. A hall tree is a large piece of furniture placed in a hall near an exterior door which allows a place to hang hats and coats, as well as a bench for putting on and taking off shoes. This particular one had beautiful cast brass hooks and a bit of whimsy in its late Victorian design.

The reproduction was going to differ from the original in two ways. The first was that it would be made from Walnut rather than Oak because the customer had a large quantity of old sawn Walnut. The second was a design modification. The original had a bench with turned legs below it. The reproduction was to have this area converted to a frame and panel storage box with a hinged lid in the seat. This would allow for extra storage and is commonly seen on other hall trees of the same vintage.

When I set to reproducing the original I debated whether or not to model it in Sketchup. Why bother when I had the original in hand to take measurements from? I initially decided to draw the model so that I could design the joinery and see how it would interact with the rest of the model. I didn't want to cut tenons that would interfere with each other or produce weak spots in the joinery. I did stop short of a full rendering of the piece. I decided that I would make templates of appliques that were cut by a bandsaw and several other extraneous parts directly from the piece, because they did not directly relate to the initial design and also the modifications to the area below the seat.

Once the model was rendered, I brought the laptop into the shop with me (an old one that could get a little dusty) and set to work. I found that my whole process for going about this project became very structured and ordered as a result of having the design in hand. In addition to the Sketchup program, I also used a couple of plugins to assist me.

The cut list plug in allowed for an ordered list of dimensions to be produced which sped up the process of rough cutting all of the boards, as well as allowing me to better organize what wood came from what board, minimizing waste. In terms of measuring from the drawing, I found the Eclate-Deplace model explosion tool to be helpful in being able to access each individual component without having to copy it or drag it out of the model. Had I known about the full size template plug in, I might have modeled all of the appliques I spoke of earlier and printed templates to use.

I could go on and on about this, but I guess that my point is that Sketch up has not only revolutionized the way I design furniture, but it has also helped to organize the way in which I execute these designs in the shop. I found myself constantly going from the saw to the laptop to check a measurement or look at how one component would interact with another. All of this made me work more efficiently and took all of the guess work out of the process. If anyone is interested I have posted several detailed posts on my blog showing how I made this hall tree. The blog address is http://www.johnmarkpower.blogspot.com.

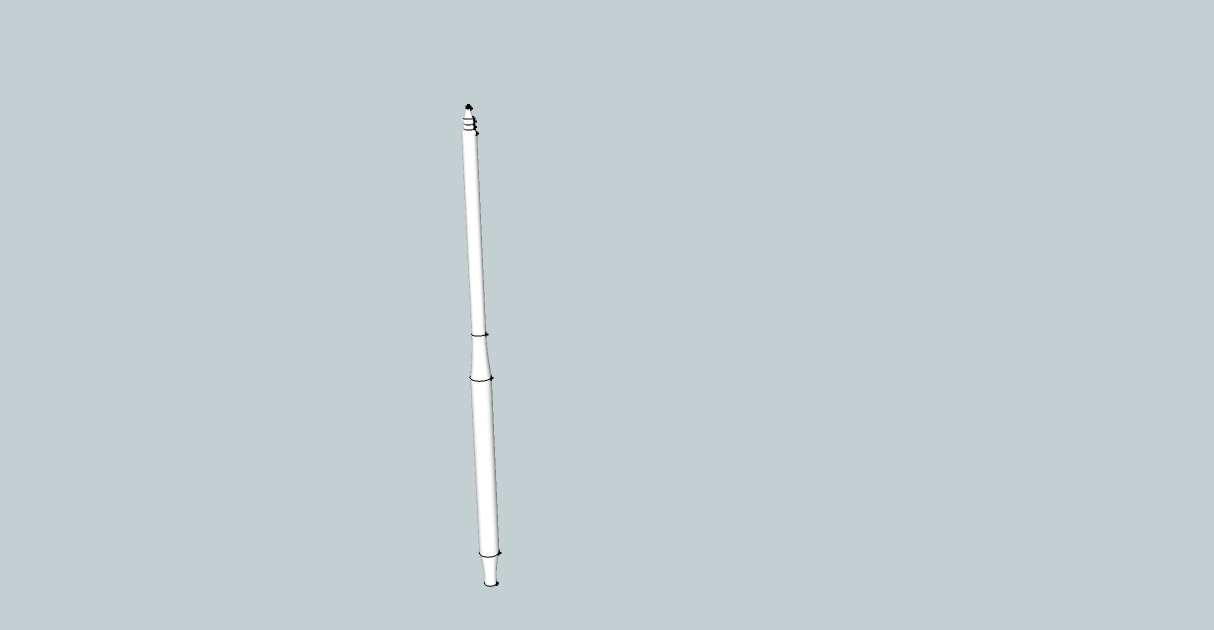

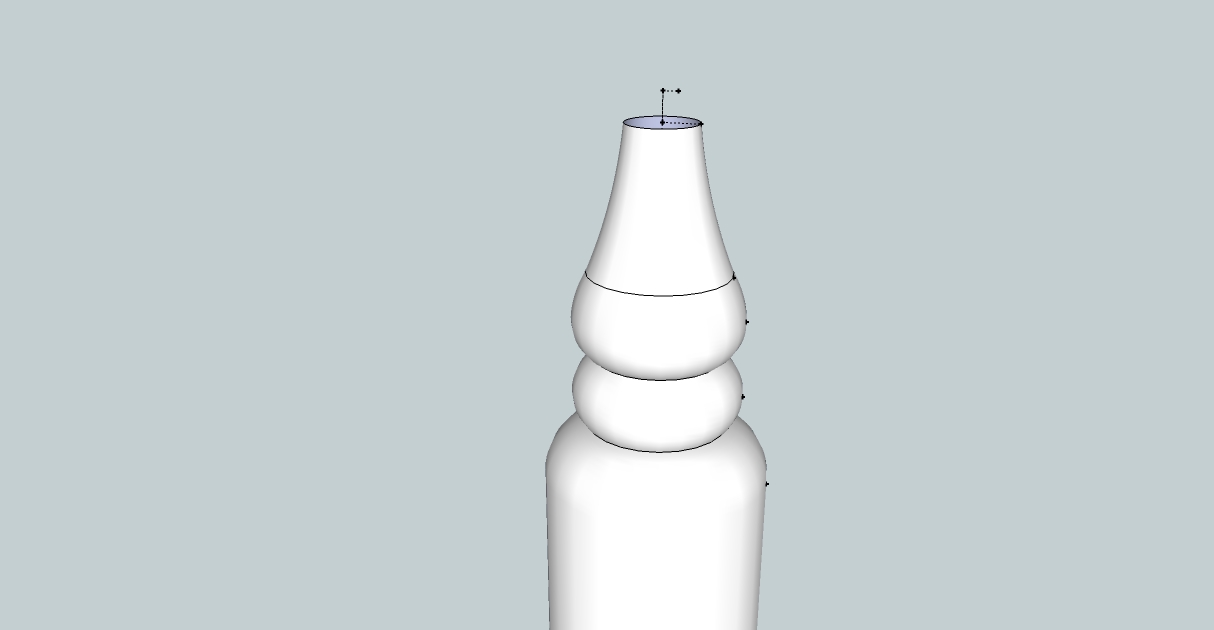

I have attached a few photos below. The first is of the original hall tree. The second is of the model. The third shows the reproduction hall tree and the last shows the original and the reproduction side by side. Thanks to all of the authors of this program, the authors of the plugins, And all of you ,especially Dave Richards, for the online guidance provided on this forum.