@pcmoor said:

for doors use flip along axis instead of using a left and right component.

i understand the "flip along axis" concept you speak of, but i have no idea how to implement it in the sub-component of a dynamic component (such as the door on a dynamic cabinet). for instance, i'm currently using the latter method you mentioned (i have two door components, one left and one right, and the left door stays hidden when the cabinet is "hinged right," and vice versa). i would love instead to use a single door that can be hinged either left or right. but when i try to do that, i get door rotation and door location issues.

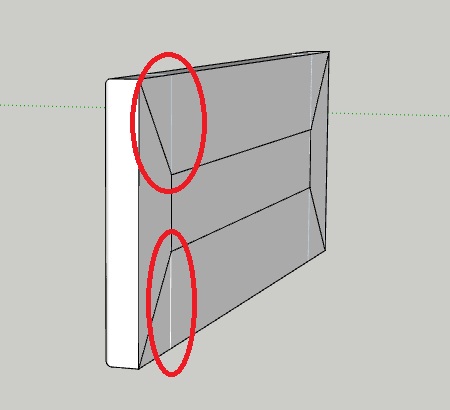

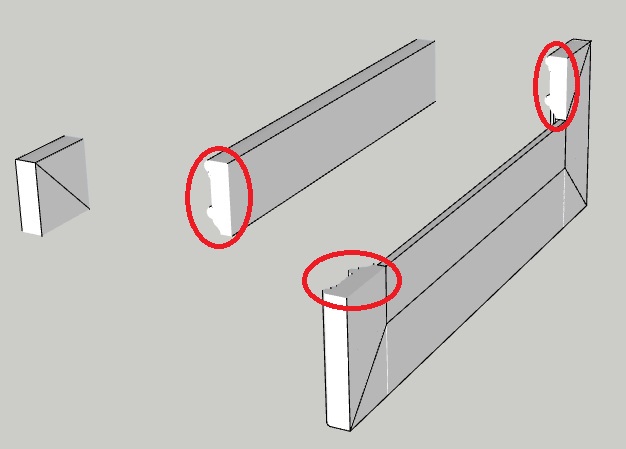

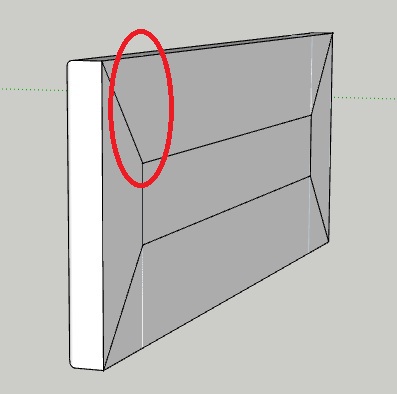

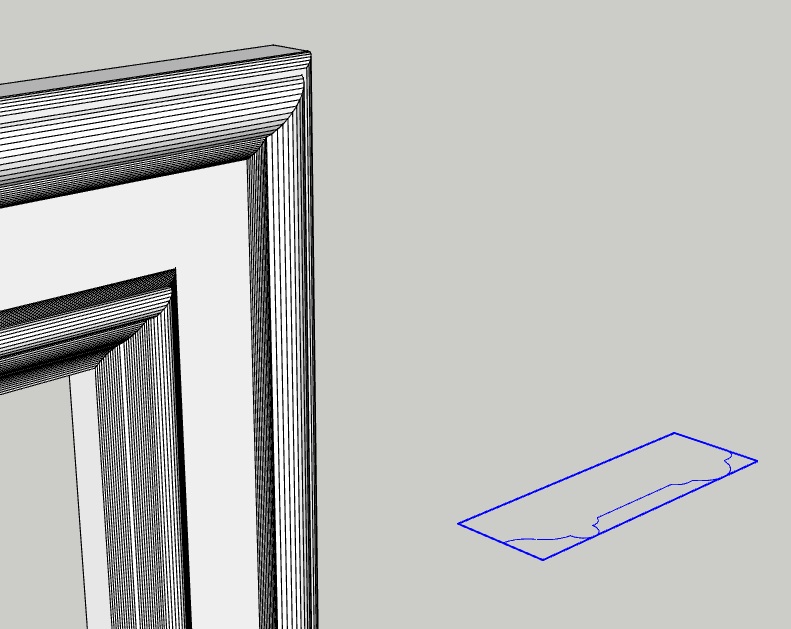

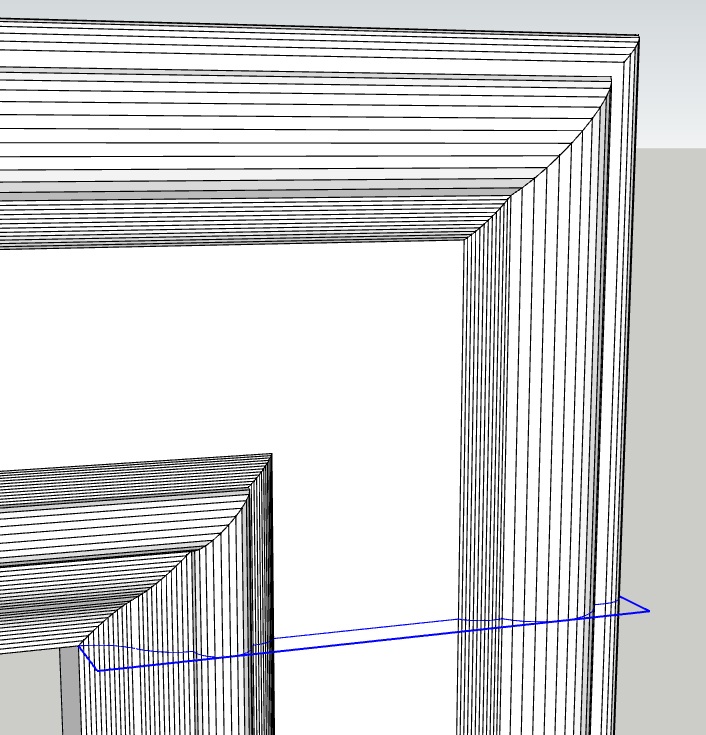

W1D.skp

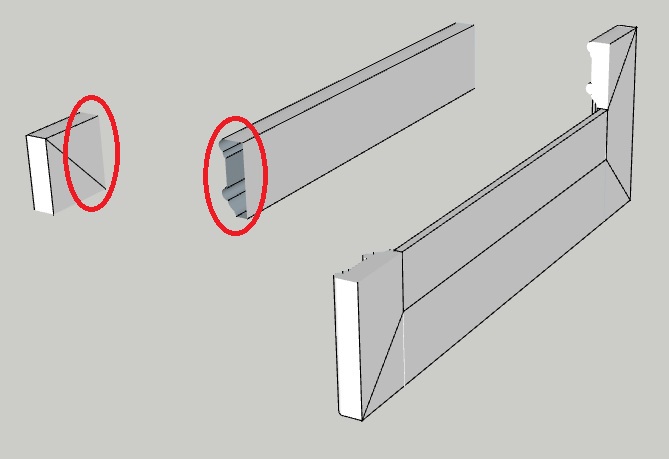

above is a single door wall cabinet (designed by Exitenz) that i found in the 3D Warehouse, and it uses only a single door component that can be hinged left or right (as opposed to using two door components like i did, and keeping one of them hidden at any given time). the door position and rotation formulas make sense to me when i look at them in the component attributes window, but only if the door's component axes change when the hinging changes from left to right or from right to left. in other words, his door must work as hinged left and hinged right b/c it flips along an axis whenever the hinge selection is changed...and this is what i'm having trouble with. the only way i know how to perform such an action is to right-click on a selected component and use the "flip along component's red/green/blue" function. Exitenz's wall cabinet does this automatically when the hinging gets changed from right to left or vice versa...play with his model and see for yourself. anyways, the reason i get door position and rotation problems in my own model is b/c my door's component axes don't reposition (due to a flip along a particular axis) upon a change in door hinging. how do i go about this? here is my model so you can see what i've done so far:

W1D_one_door_swing_both_ways.skp

@pcmoor said:

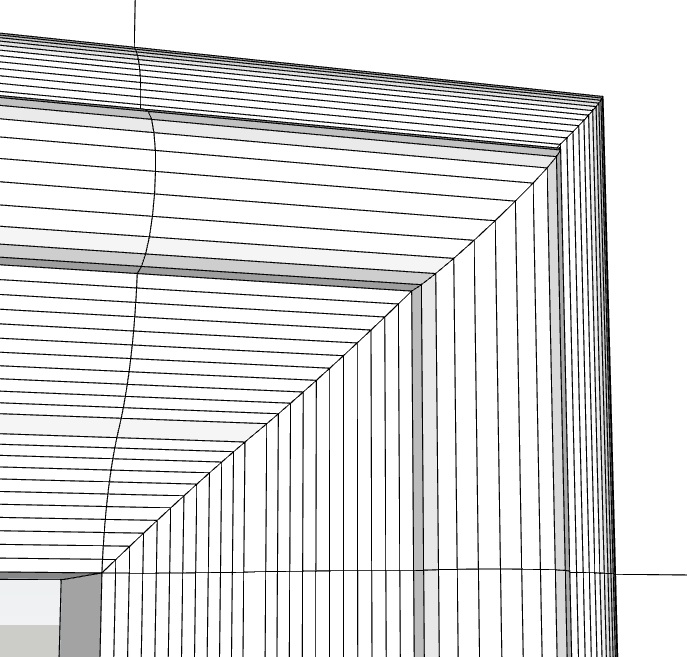

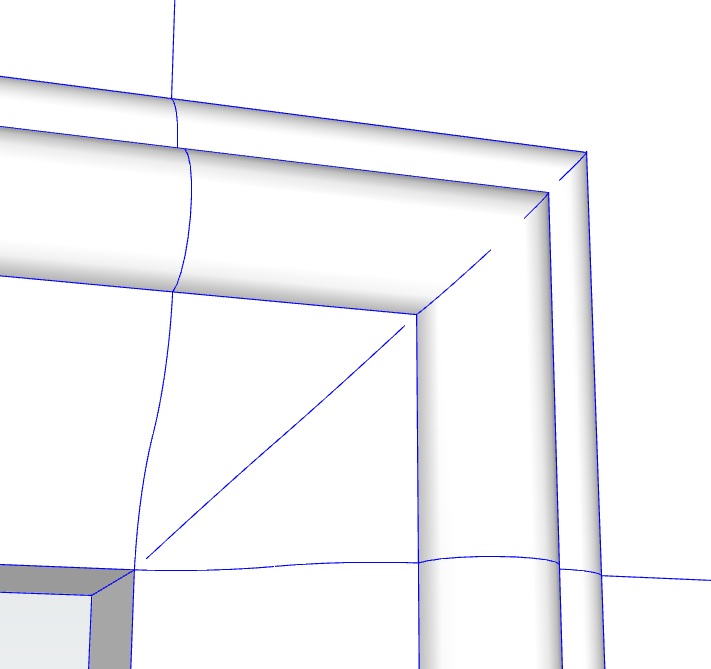

for rotating function, you need to place an extra component wrapper to protect contents

i'm not entirely sure what you mean by this. are you saying that component that is meant to rotate (such as a cabinet door) must be a grandchild to the main component (the cabinet itself)? Exitenz's model above had a component wrapper <F_W1D> around the actual door component <DRBB#1>, making <DRBB#1> a grandchild of the actual cabinet <W1D>, and i don't quite understand why that's necessary...

@pcmoor said:

don't hide different types of doors,knobs or other components; swap them instead.

what do you mean by "swap them instead?" are we talking about the use of layers, or perhaps adding and/or removing parts from an external library into our model?

TIA,

Eric