Layout is so slow !

-

Hello everyone

Is there any tips for layout? It just annoys me to much as it’s so slow! I organise and layer and much as I can but do people layer per page so when moving on the next page they can turn off view ports in that page ?

I do like sketchup but layout for me is pretty pants and it makes me want to head back to autocad.

Thanks.

-

use the lowest setting for display.

-

use the lowest setting for display. Use raster and low quality. Change to Hybrid if you want before printing.

-

Is it possible that you are simply using over bloated models.

You have changed from Mac to Win expecting a boost in performance but could it just be less than efficient models.

In my experience quite often when people upgrade the hardware to get better performance we find that a few changes in workflow benefit them far more.

If the model is struggling in sketchup it's almost guaranteed to be sluggish in layout. -

thank you all,

i have seen a few old posts on here mentioned the same thing that also mentioned a messing model. I will revisit my model and see what i can do.

-

Attaching a file is a good way to get advice on whether it is the model or something else. If we find the model is ok then we would be able to start tracking down if you have hardware or driver issues.

Otherwise everything is guessing. -

Hi all

i have shared the SU model and the start of my layout for. I am all ears to suggestions as my layout in so clunky.

thanks

shared link below:

-

There are many issues with your model. So much so that my computer struggles with it.

You have some really bad geometry in the pumps and piping. Various components that have been scaled down significantly that should really have their definition scaled. You have reversed faces, but as you have set the back faces the same as the front it is difficult to tell.

You are using Layers/tags incorrectly.

I'm guessing you imported things from elsewhere.

My computer is unable to cope with cleaning it up. -

Thanks for the comments are you able to proivid examples of correct use?

just to comment on the following?

-

geometry bad? how so? i use avk 3d models and connect flange to flange and push pull the pipe?

-

how am i using the layers and tags incorrectly? surely this is down to my own workflow? i have existing and new folders which i then put in there new installation and existing site set up?

-

yes of cors i have imported things from else where such as from the Xylem website, i have used flygt pumps which are the actual pumps using on site so the pedestal will be correct to align the new pipework to ensure the geometry is correct as the existing site building and new pipework route is very tight? it was a step file which i converted into SU.

Are you able to maybe send me a example model which i can then maybe see how i can improve on?

thank you

-

-

Dave's given you some good answers in your other thread so I won't double up here.

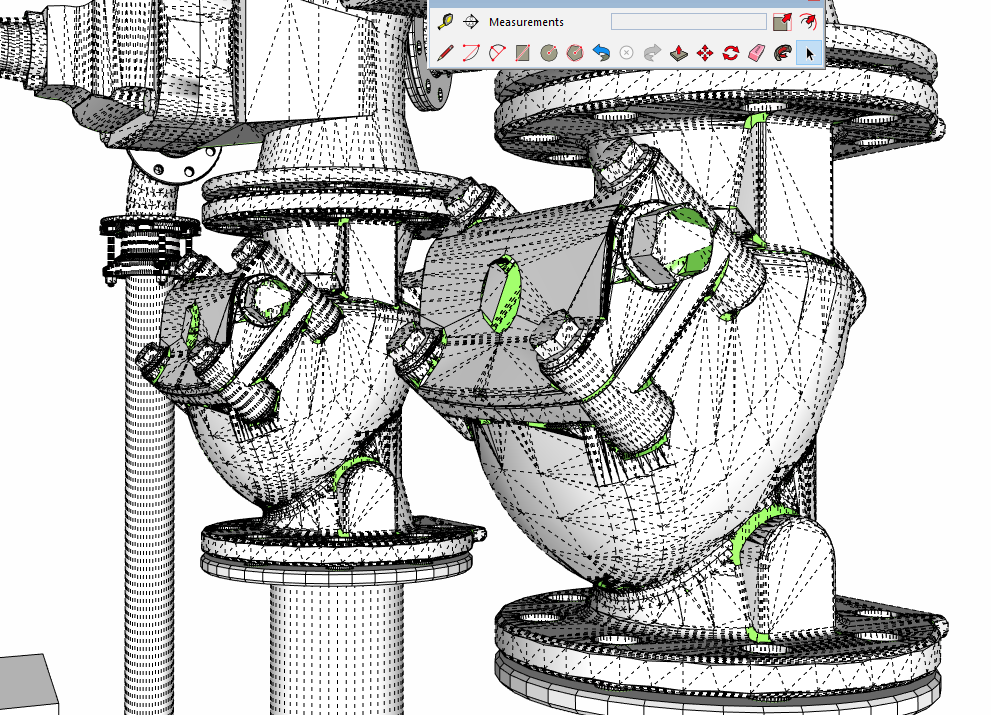

I will post an image of what I mean about bad geometry.

The green you see here is looking in through holes in the model. Also the huge amount of triangulation and over complex shapes that Dave has already mentioned.

-

Thank you for the comments.

that was an imported model that used the skrimp tool on to try and get the size down of the file thats why the model has the holes in i guess, i didnt model them. Is there another way this can be done without wrecking the imported model but still reducing size?

in regards to the other post on the thread i am not sure if that is also true as i often find lines etc missing from the exported to DWG also and the models have loads of crazy little lines that are not showing on the SU model.

SU works well with anything drawn in the software but any models imported then export via dwg it has a mind of its own.

thanks

-

Well unfortunately sketchup works with sketchup models, how well the imported stuff works depends on how it is converted and how it was created to begin with.

Your model isn't particularly complex and could probably be modeled quicker than struggling with importing things. Or just some decent cleanup of the imports.

Here for example is a flange (one of several in the model) that is made up of over 200 components when it could be just one. This sort of over componenting can wreak havoc with performance in both SU and Layout.

Here I have simply exploded the components to form one component, it has the added benefit of removing the enormous scale of the tiny components. I haven't reduced any of the detail, but personally I would as it is over detailed for what it is. The main circle has 94 segments and considering when in place it can't be seen it is a bit of overkill. Your pipes also have internal skins, useful for close up detail but more performance sappers in a full model. The 3d man is another questionable addition, often 2d face me components are enough.

Basically I'm just trying to point you in the right direction with understanding how to get the best from sketchup. It needs clean and efficient modelling, and it is fairly easy to achieve within the program, but can be troublesome when you bring in outside elements.

-

Thank you Box this is great and makes perfect sense.

Is there a way i can clean the gate valves also the NRV' to remove alot of the triangulation? I have just tried to skrimp it again but it does a terrible job

I suppose i am trying to cut corners a little and would probably benefit more if i took my time, but i am not a design engineer i am a project engineer so i dont have as much time as i would like to design all day like i would like to.

I have a comprehensive set of blocks for pipework etc for cad but i use Autocad Lt, so i am trying to incorporate a 3d element into my designs but i get the horrible mess during import seen in the picture. i would use SU more but when dimensioning i feel like it does always snap to where i would like which doesn't feel me with confident. For example if i am dimensions pipe centres.

-

Do you have the original imports in step or better still stl format?

-

If you go to the 3d warehouse and select product and type in avk. Then go down and look for it on there, there is a NRV 3rd line down which is DN250 which is bigger then the DN80 which is in my model but it will show you what i downloaded.

all the pipe work and valves are from this product line as AVK are a leading water industry manufacture.

-

have you got the original step file? If you do I can probably convert it to something usable.

-

It isnt a step file it is a SKU file but i have put it on the link below

-

I'm sorry but those models are just plain awful. Very bad conversions from another format. Both the one you linked and the ones in the warehouse.

I'd either find originals or model them directly. -

Thank you Box, i much appreciated you trying on this model.

-

I agree with Box. These things are awful. It goes back to what I told you about making lean and clean models.

I should have dug into your model further. I would have seen this and called it out. It started to feel like I was just piling stuff on in your other thread, though. Remember, GIGO applies here.

If you must use these components in your models, you'll need to go through them and clean them up.

Advertisement