Please help!

-

No matter what I do I cannot get a hole through a .0750" thick wall.

The wall is perfectly parallel on both sides. When I use the push/pull tool and type in the exact thickness of the wall it does not cut a hole. Also tried pushing hole past interior wall and then using intersect faces, but that has the exact same issue.

Deleted wall completely, drew new wall, same problem...

No idea what the deal is but this is ridiculous! -

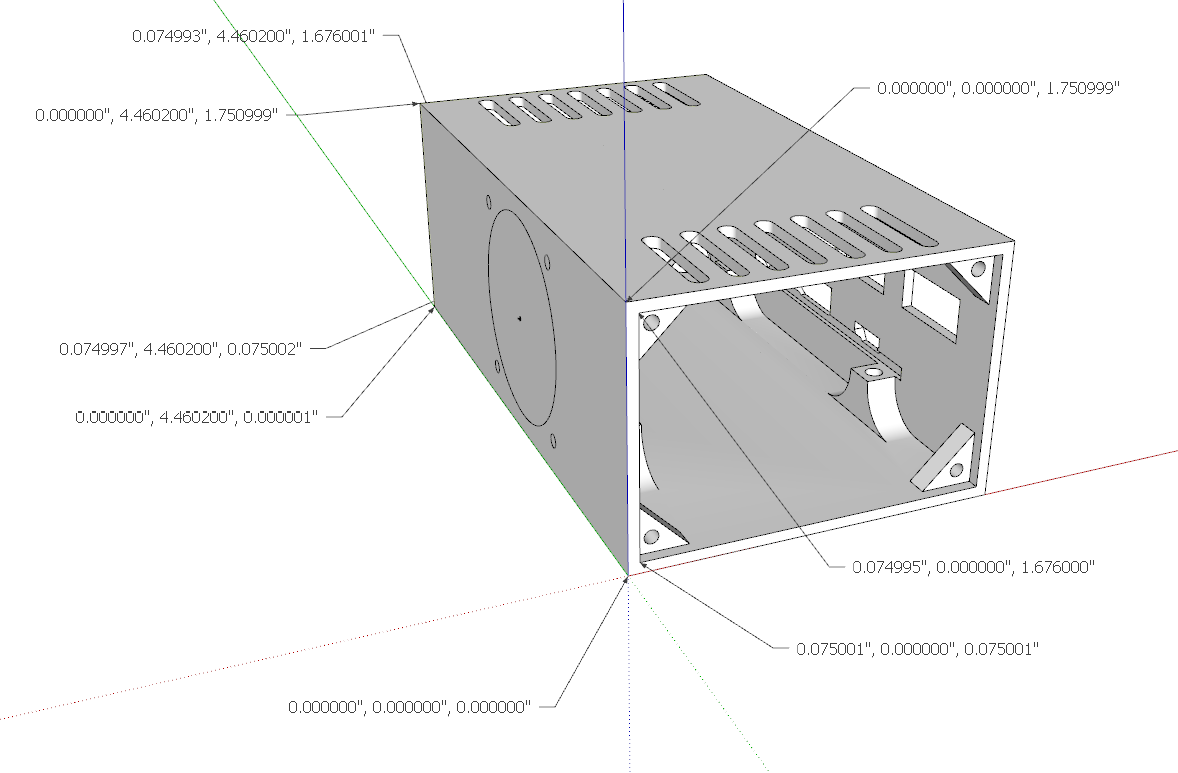

How did you go about creating the model? The inside face is not parallel to the outside face. If it was, the X values of the corners would all be the same. Note the outside corners all have an X value of 0.000000 in. All of the X values for the inside corners ought to be the same, too. Maybe 0.075 in.

Since the inside face is not parallel to the outside face, Push/Pull won't open the hole. You could get the holes by pushing a bit farther through, selecting the geometry, and running Intersect Faces before erasing what you don't need. Personally, I would redo the model so it's right.

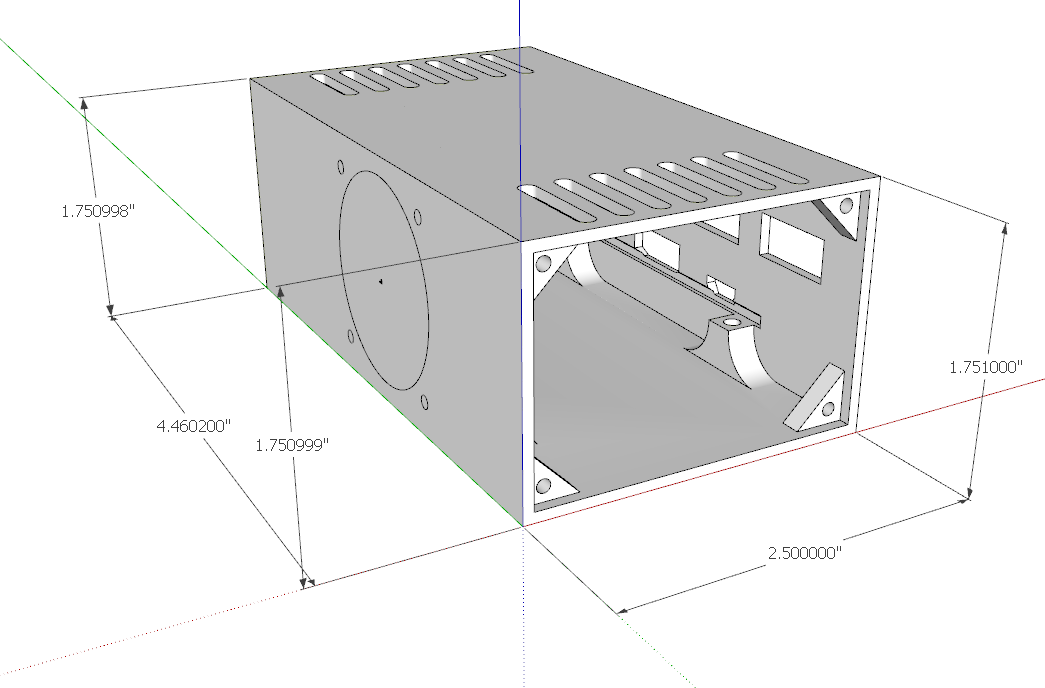

Are you planning to 3D print this thing? If so, and if you are going to redo the model, set the units to meters. and enter your dimensions as if the are the meters. That is, make the box 2.5 meters wide and 1.750999 tall (if that's the correct dimension. It's 1.750999 inches tall now.) Then export the STL. When you import the STL into the slicer, tell it the units are inches not meters.

-

Thanks for looking at this. I don't understand how it's possible that the walls are not parallel. I even deleted them then redrew one and pushed it to .0750". I have the precision set to .0000" and always type in exactly what I want.

I tried pushing the holes well past the interior wall and using intersect faces with selection, but even that still does not cut a hole through the wall.As for 3D printing this, yes. That I do not have any issues with, and I have never set to meters, or mm. I always just export to mm and it works perfectly without any additional steps.

What plugin are you using to show these measurements?

No way I am redrawing this whole thing! I'll figure out how to fix it.

-

I don't know what you did but you managed to get these faces out of parallel. I didn't use any plugins to show the coordinates of the corners. I just used the native Text tool. I did increase the Precision to show more decimal points.

@mochanic said:

No way I am redrawing this whole thing! I'll figure out how to fix it.

OK. Best wishes on getting it fixed.

-

No idea what happened, but I was finally able to get the hole to push through. Thanks for your help!

I just wish I knew how it got like this to begin with. -

I suspect it was just imprecise measuring which you couldn't see with Precision set as coarse as you had it.

Do you really want these dimensions for the exterior of the box?

-

@dave r said:

I suspect it was just imprecise measuring which you couldn't see with Precision set as coarse as you had it.

Do you really want these dimensions for the exterior of the box?

Yes, the length is determined by the circuit board that goes inside, the height was supposed to be 1.750" and the width is correct at 2.500"

I have already printed 1 case, but I was making another version of it with a fan on the side. And now yet another version with more options for fans.

-

I expect those differences in height dimensions won't really be a problem but with correct modeling techniques, those wouldn't occur at all. As long as it works for you it's fine but that's part of what caused your problem. That imprecision can be avoided though.

-

I literally type in the exact numbers that I want every single time. I have no idea how it would have changed, but we are literally talking about less than 1 thousandths of an inch. This will not be a problem for anything, especially a 3d printer!

Sketchup has SO MANY issues and one day I will take the time to learn Fusion 360 and forget all about these stupid issues that nobody cares to fix.

-

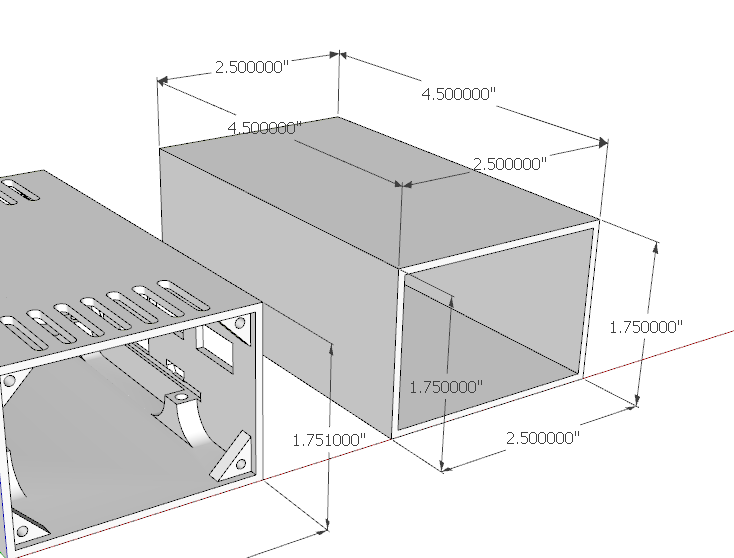

I think the issues are user induced. I frequently model small objects in SketchUp but I've never had any issues with dimensions like your model has.

Here I drew a rectangle, Offset to create the wall thickness and Push/Pull to length. Nothing special and dimensions all as expected.

Why do you say "someday"? If you have problems with SketchUp, why continue with it? Why not just switch to Fusion 360 if that will solve your problems?

-

Yeah that's great, anybody can draw a simple rectangle, but once you add all the rest of the stuff it somehow gets wacky. My model didn't start out that way! You think I typed in 1.750999"?

I think it had something to do with snapping. I need to turn it off.Because I don't have time to learn a new CAD program. I have used SU for at least 15 years and have made thousands of models.

-

If you move the model to the center of the axle, the hole is drilled. Interesting. Is this a bug?

Click on the image for animation.

-

@ecati said:

If you move the model to the center of the axle, the hole is drilled. Interesting. Is this a bug?

Click on the image for animation.It's funny that you noticed that. That's actually what I did to get it to work, but I didn't realize that was why it worked after moving it.

(The model was not at XY axis because it was in it's place on the machine itself.)

Advertisement