Hot wire foam cutting - Anyone?

-

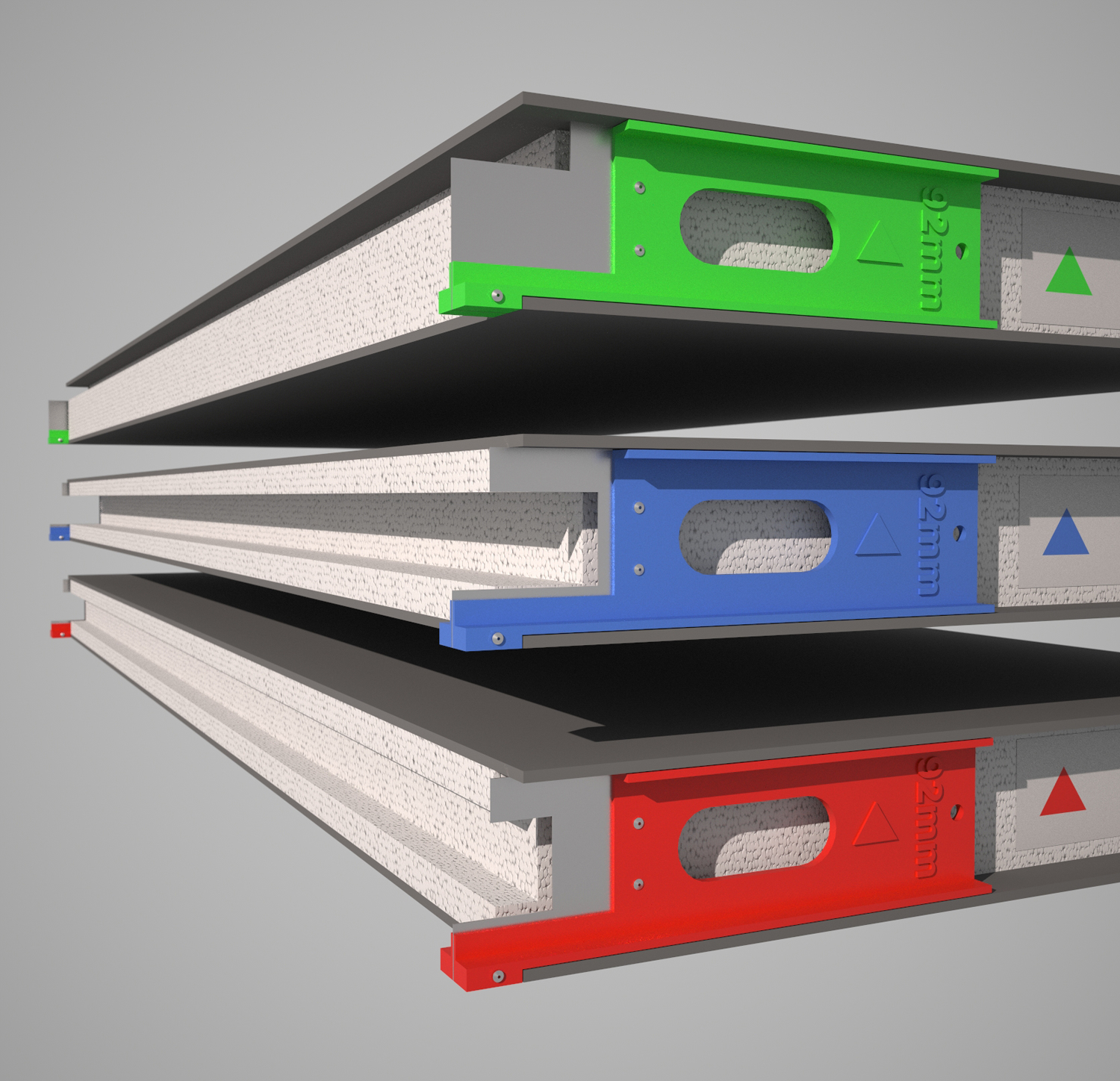

I'm designing some edge profiling guides for hot wire cutting the EPS (Expanded Polystyrene) core of Structural Insulated Panels, and wondering if ANYONE has had any experience with manual hot wire cutting long (up to 3.6m) lengths of EPS.

There are a significant number of logistical benefits in production, but not sure if we are being unrealistic.

-

I did a lot of hot wiring some years back, basically slicing poly sculptures up into layers for templates. My experience of it was that specific heat and speed of cut where critical to accuracy. Too hot and slow and you melt the cut, too cold and fast and you tear the material.

Send me enough panels to do my upper deck and I'll experiment for you

-

@box said:

I did a lot of hot wiring some years back, basically slicing poly sculptures up into layers for templates. My experience of it was that specific heat and speed of cut where critical to accuracy. Too hot and slow and you melt the cut, too cold and fast and you tear the material.

Send me enough panels to do my upper deck and I'll experiment for you

Yes mate, they have found that with general hot knives! Seems to be somewhat of a disaster!

Hopefully, they get around to testing soon with a few dummy knockups! The cool thing with these guys they are right into testing and development. They have installed a full load testing rig so they can have certified and cladding or corner construction so we can rapidly develop the system.

-

The problem you will have that we couldn't overcome, was that the longer the wire the more it stretched as it got hot and sagged too much to be accurate. If you tighten it to much the heat caused the tinsel strength to drop and it would snap. Good luck!!

-

Have you looked at lasers? They are relatively cheap these days, and size isn't a big issue. We have one with a cutting bed of about 2.5 x 1.6m. And you can buy just the laser unit and build your own jig. Keep the laser fixed and move the panels perhaps if the shapes are simple.

-

I vaguely remember seeing a 'How its Made' episode on this and I think its this one: https://youtu.be/XXMque-pLhA?t=2m45s - The link starts at the relevant point.

Here's another one without commentary: https://youtu.be/PVGjvdFjnYI?t=40s -

I understand Nichrome wire is preferred.......and some type of auto-tensioner......both perhaps obvious.

I did a fair bit of research while considering making carbon fiber parts........wire cut foam was to part of that process.....ultimately never made the carbon fiber parts.

Advertisement