Medeek Wall Plugin

-

You mean like this? (click to view animation)

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

Version 1.1.7b - 12.25.2019

- Enabled temporary (construction) dimensions for the wall split tool.

- Added a vertical offset to the holdown symbol(s) to eliminate Z-fighting with the wall panel top plate.

-

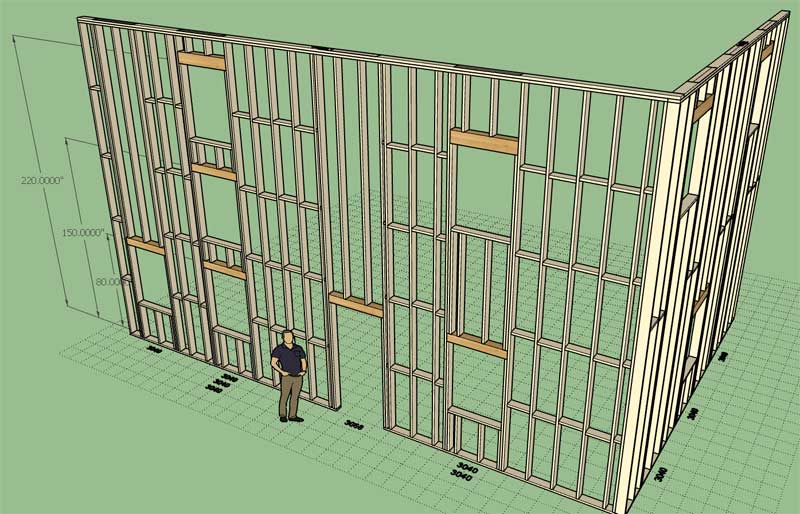

Something that I have had on the to-do list for quite a while but have avoided it due to the many permutations and pitfalls: Stacked Windows

I have some additional testing to do, but so long as the windows line up (same x-position along wall) and they are the same width (as shown) then the algorithm seems to be successful.

The real problems arise when the windows partially overlap, or even if they are aligned but the windows widths are different. Those type of scenarios create all kinds of framing permutations which then becomes a real can of worms for the logic. I may eventually tackle it but for now I’m going to make some simple assumptions, so that I don’t become too bogged down with this problem.

-

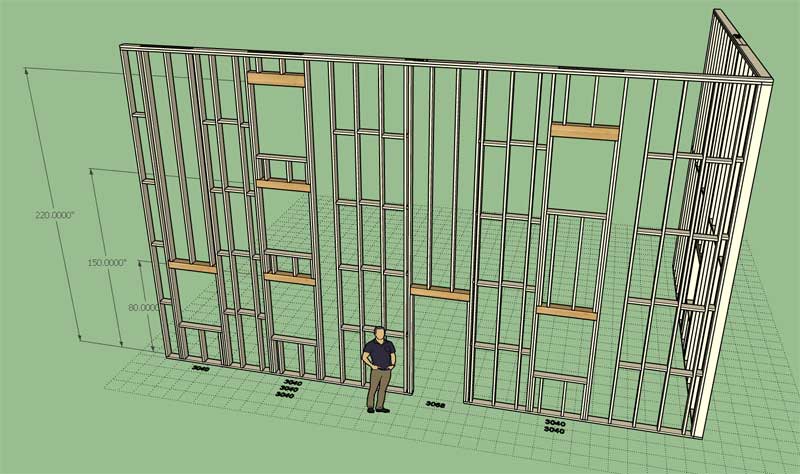

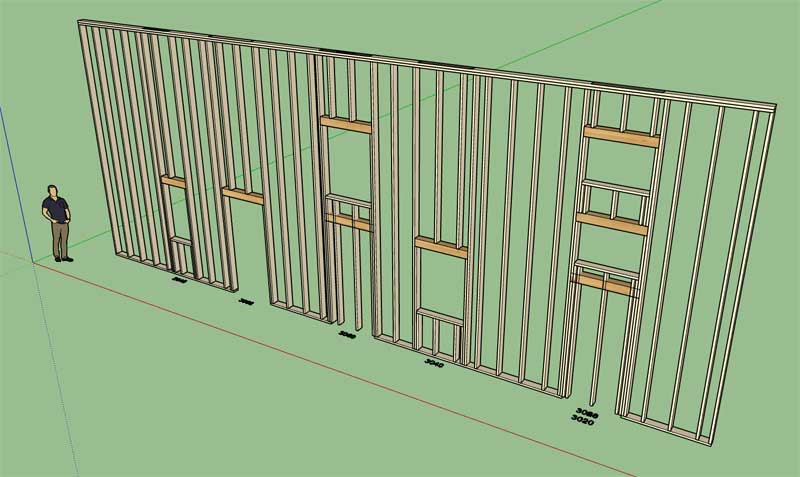

My original algorithm was too simplistic, it did not account for multiple window stacks within a wall panel, now I have that resolved:

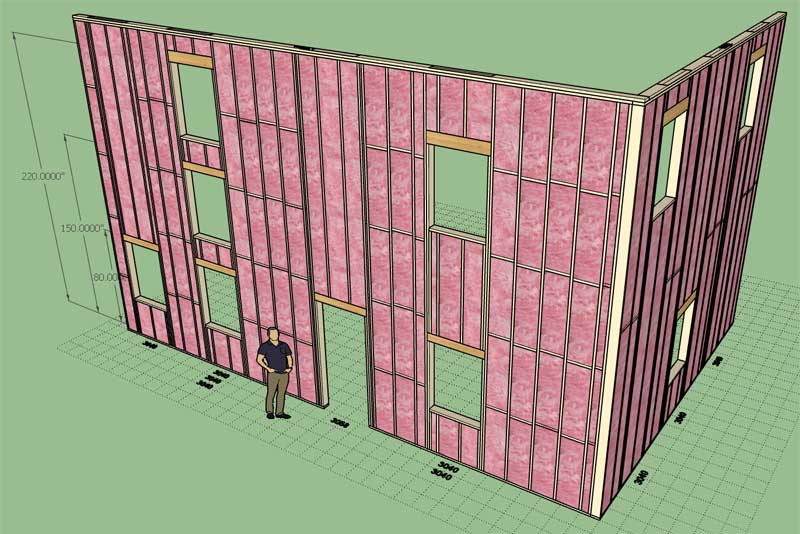

The final step is to make sure that the blocking and insulation modules are compatible with stacked windows. As can be seen in this screen capture there is still an issue with stacked windows and blocking (right side).

-

Version 1.1.8 - 01.06.2019

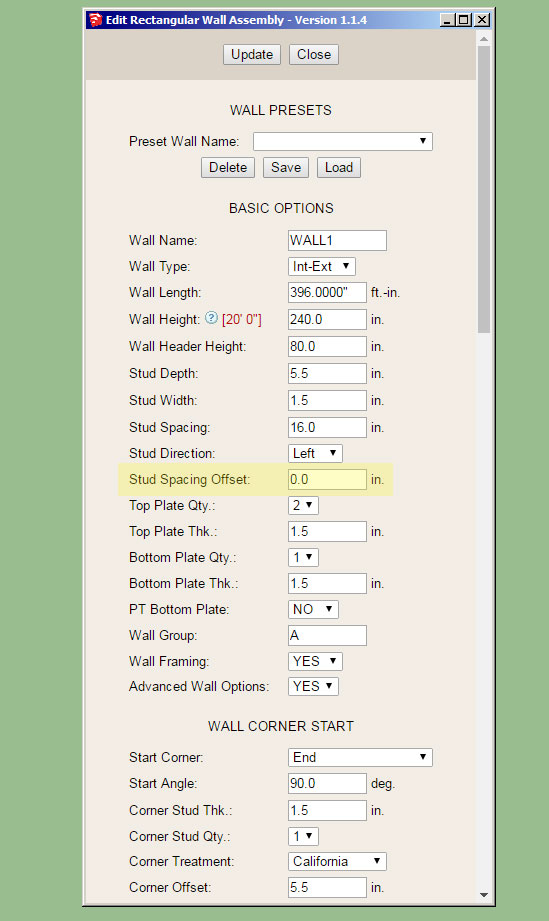

- Added a "Stud Spacing Offset" parameter which allows for custom stud spacing/placement.

- Enabled stacked windows within a wall panel.

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

Both of these items have been on the to-do list for quite some time and together constitute a fairly substantial upgrade to the functionality of the plugin. The offset parameter has been requested numerous times over the last few weeks.

This update does not yet allow for stacking of windows/doors or doors/doors. However, now that the logic path has been established I should be able to enable these additional possibilities much more quickly. I will see if I can knock this one out this coming week.

-

The same stacked windows as below but with the insulation included:

I haven't finished the window/door stacking algorithm yet but it occurred to me that window over door is the most common configuration and not the other way around. In fact, I really see no reason to have a door over door algorithm either. Correct me if I'm wrong.

-

@unknownuser said:

I really see no reason to have a door over door algorithm either. Correct me if I'm wrong.

No doors' emergency exit on the upper levels possible ?

-

Now looking at stacked windows over doors:

It's also possible that you might have multiple stacked windows over top of a door as shown to the right. A few things to consider here.

-

@pilou said:

@unknownuser said:

I really see no reason to have a door over door algorithm either. Correct me if I'm wrong.

No doors' emergency exit on the upper levels possible ?

Yes, but in that case it will probably be a separate wall panel and not balloon framed to the second level.

-

Version 1.1.9 - 01.09.2019

- Enabled stacked windows over doors within a wall panel.

Note that for this to work correctly the king studs of the window(s) and door must align and the windows and doors must be centered on the same location within the wall.

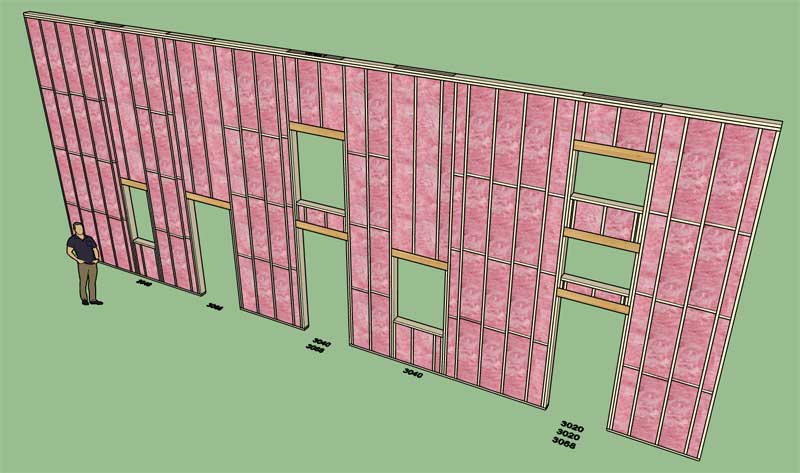

The framing, blocking and insulation modules are now updated for stacked windows and stacked windows over doors.

-

As I was comparing the window and door modules this evening a number of things jumped out at me. I've made some updates over the last few months to the window module that did not get propagated to the door module. Here is a short list of items I will work on in the next couple of days to bring the door module up to par:

1.) Arched, gothic arch and half round door openings and doors.

2.) Variable king stud width for doors

3.) Variable trimmer stud width for doors

4.) Built up headers for doors

5.) Trimmer extend option for doors (for built up headers that have a bottom plate, common construction method in Alberta CANADA).Note that these updates are specifically for man doors and do not apply to garage doors or garage door openings. That will be work for another day.

*** IMPORTANT***

I'm also considering making the wall plugin able to insert windows, doors and garage doors into generic walls (non-Medeek Walls), similar to what one is able to do with the electrical plugin. I actually don't think this will be too difficult and will make the Window/Door tools more universal and flexible for the user who may or may not always use Medeek walls in a given project. -

1 thru 5 of the items list previously are complete and now functional (not released yet).

First look at an arched doorway:

I now need to complete the door trim, casing and install modules for an arched door. Eventually I will provide the option for all of the various door types (eg. six panel, half glass etc…) however to start with I will just enable the solid arched door.

There will also be the permutation involving sidelites and double sidelites with arched doors, but again this will be work for another day.

-

You can set the framing mode of the plugin to 2D or “no framing” 3D mode on a wall panel basis or even set the default behavior in the global settings.

Once you are comfortable with your design you can switch the wall panels to the full framing mode. The no framing mode generates the wall framing as a single solid. Perhaps I need another tutorial that explains this in further detail. Switching between modes is completely automated, just one mouse click after you right click on the wall assembly(s).

The idea behind the 2D and 3D No Framing modes is to keep the model as lightweight as possible during the early design phases (ie. don’t over complicate things with framing) while at the same time providing enough information to fully understand the design and its dimensional constraints/properties.

The 2D mode is great for the initial layout but eventually one of the 3D modes will be required to fully grasp the various wall heights and possibly stacked window layouts etc…

-

First look at an arched door frame and (solid) door:

I think the only thing still pending is to make sure that wainscoting module can handle arched doors and then I will make this upgrade live.

-

Version 1.2.0 - 01.15.2019

- Added (segmental and half round) arched doors to the door module.

- Enabled variable king stud and trimmer stud widths for doors.

- Enabled built-up headers for doors.

- Enabled the trimmer extend option for doors.

- Added casing "Style C" for rectangle and arched doors (gypsum wrap for interior wall openings).

I've also addressed a few minor bugs and issues with both the door and window modules.

Currently the only arched door style is a "solid" door however I can add additional styles upon request (ie. half glass, double, full glass, six panel etc...)

-

View models of arched doors here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

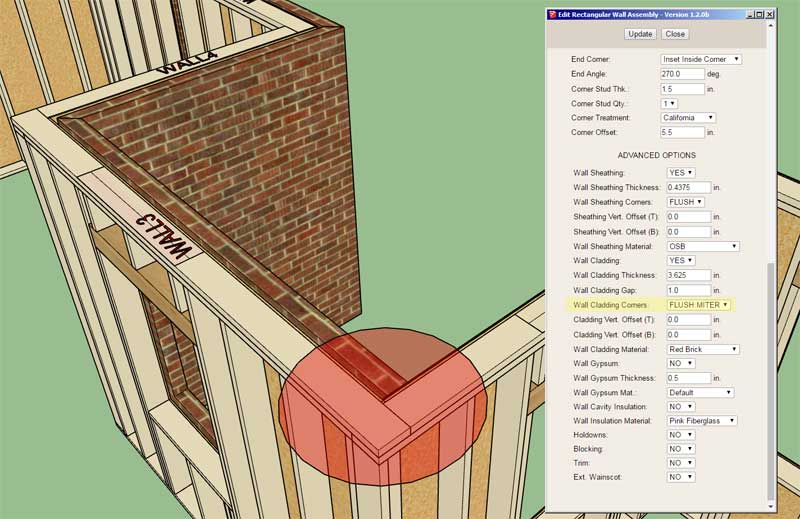

Version 1.2.0b - 01.16.2020

- Fixed a bug with wall presets introduced with the addition of the stud spacing offset parameter.

***** CRITICAL BUG FIX *****

If you have previously installed Version 1.1.8 thru Version 1.2.0 then you will want to update your installation to this latest version. The bug was introduced into the wall presets module on 01/06/2020 when the stud spacing offset parameter was added. This bug fix should resolve that bug and allow the creation of wall presets with this latest parameter added to the list of wall parameters. -

Version 1.2.1 - 01.17.2020

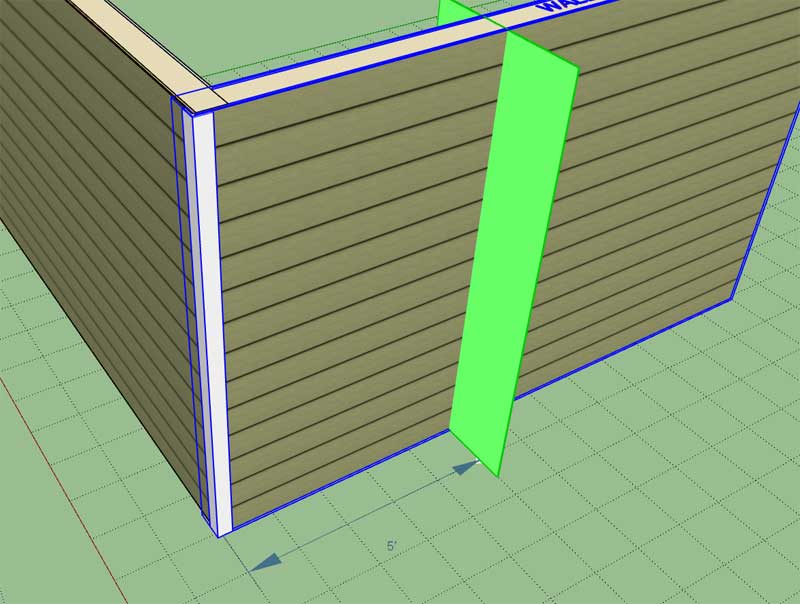

- Added FLUSH:MITER and MITER:FLUSH option to the Wall Cladding Corners parameter.

- Fixed a second bug with wall presets introduced with the addition of the stud spacing offset parameter.

The additional options for the Wall Cladding Corners parameter is specifically for situations where you encounter a wall cladding material/thickness change at an inside corner as shown.

-

Version 1.2.1b - 01.17.2020

- Added (segmental and half round) arched double doors to the door module.

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

Looking good Nathan!

Advertisement