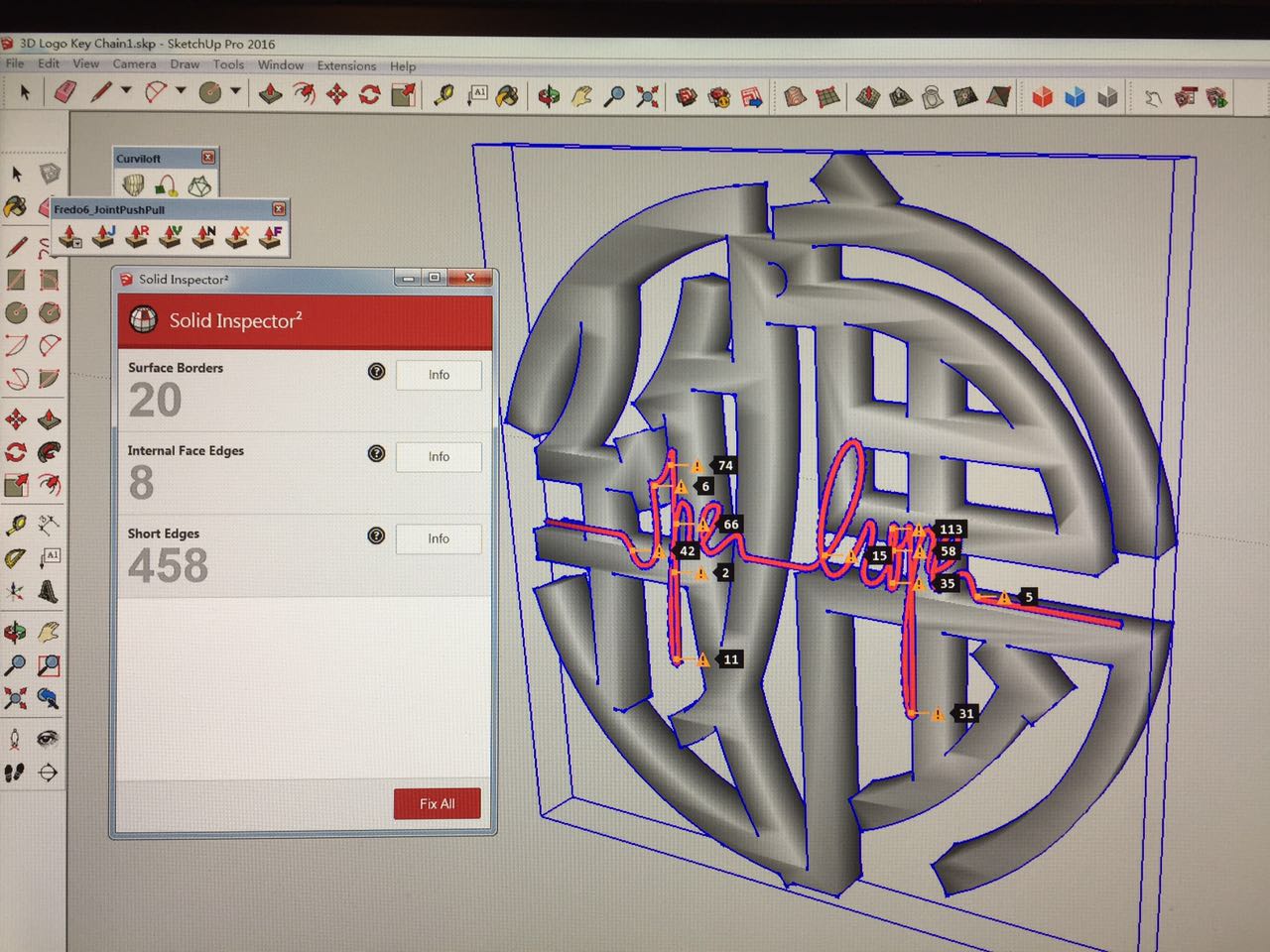

Issues about Make Solid for 3D Printing

-

Last time used the Solid Inspector2 to fix all surface borders, internal face edges, and short edges by creating some new geometries but this time just can't get it fixed. Should I be re-creating the whole thing with the problems? Don't get it why it gets so many short edges by using Follow Me tool to create a tube looking around a bunch of lines and curves for my logo... and how would I get those faults fixed?

-

The problem shape looks really complex for follow me, with very sharp turns and intersecting/overlapping lines. You probably will need to redo the part. A few things to try before running the follow me operation are:

- Scale the part up 1000x

- simply the profile geometry to 4 or 6 sides

- separate and group the path into several pieces so it doesn't overlap, then after running the operation combine the groups using Outer Shell

An alternative to redrawing the part is to download Netfabb Basic and use it to fix the STL errors before printing. Results may vary though, depending on how bad the errors are.

-

Wow! Great answer and solution! I'll try to redo the whole thing with your great advice. Hopefully I can get it to work. Thanks.

Advertisement