3D Truss Models

-

BC = Bottom Chord

TC = Top Chord

Web = Internal (web) members of truss -

Thx for the Infos!

-

The license registration module was causing some problems in isolated cases so I've released a sub-rev. 2.1.1b to address that issue.

If you are trying to enter in your serial number and it does not appear to take, first verify that you are not entering in any leading or trailing white spaces if that does not solve the problem you may be encountering the issue at top, in that case download the latest version which should address the issue fully.

-

Valley set chest => Panel de NoueStepdown Hip Set => Panel de Panne de Rive Inclinée

Terminal Hip Set => Panel de Sablière

Northeast Hip Set => Panel de Linçoir

Metal plate connectors = Connecteur Métallique Plat

Gusset = GoussetWeb = Membrure

Web = Fiche & Contre-Fichein this following Schema "Chantignole" is false : must be "Arbalétrier" !

-

This week has been a bit tough for me to get any meaningful work done on any of the plugins, too many Christmas concerts, parties etc... but I guess its for the better. This weekend I will try to get out the update for the heel blocking and an update on the translations.

-

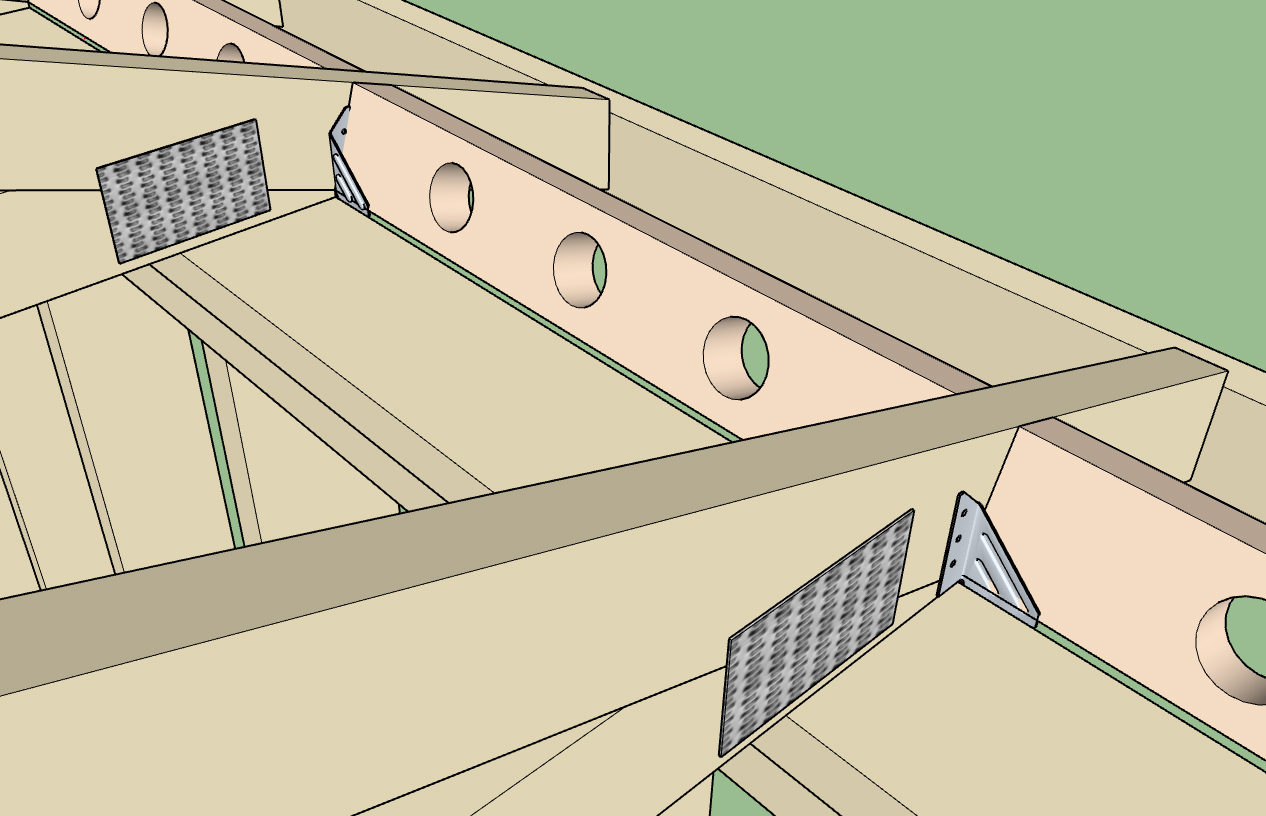

Version 2.1.2 - 12.18.2017

- Enabled vertical and angled heel blocking within the advanced options for truss roofs.

If you choose to enable vent holes the heelblock menu will prompt for the hole diameter. The vent hole algorithm will place vent holes in the heel blocking per the truss spacing:

< 12 in. = 1 vent hole

< 16 in. = 2 vent holes

16 in. or greater = 3 vent holesLet me know if this makes sense, I can always modify it to meet any criteria. If this sort of thing varies a lot per locale I can also make it more user definable.

-

This type of heel blocking is very typical in my locale (Western Washington State):

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

To end off the year with a bang and to thank our truss plugin clientele I have decided to reduce the license renewal fee for the Medeek Truss Plugin to $10.00 USD. This promotion will run until the end of this year (Dec. 31, 2017) and then the renewal price will return to its usual price of $20.00 USD.

This year has been very busy with further developments of the truss and foundation plugins. I am looking forward to the new year and another full year of new features and even new plugins and tools.

I've really appreciated all those who have actively contributed to the recent developments of the plugin, especially the translations.

A Merry Christmas to all and a Happy New Year.

-

Sorry but a more complete French translation will be at the beginning of the next year : no more free times for the moment!

Have happy new year!

-

Just some minor bug fixes for 2.1.2b, I will probably address some other minor issues brought to my attention in the next couple of days.

-

I've been thinking about adding in the option to show H1 ties for rafters and trusses:

.jpeg?quality=80&u=cjmyin&crop=0)

I've seen them mounted both on the exterior and the interior with the flanges facing both inward and outward, four possible configurations. Any preference on how these are typically installed. I'm sure there is probably not much call for these but it isn't a big deal to add in the option for those that would like to use it.

I am currently featuring Simpson Strong-Tie hardware in the Truss Plugin, not because I am specifically endorsing their products or the brand but because that is what I am most familiar with and their products are readily available in the US and Canada. Mitek also makes comparable hardware and probably has better availability outside of the US and Canada.

I'm also thinking about allowing the user to choose between and H1 or H2.5A:

-

I've had a number of new and existing clients who are running SU2018 on MacOS who are reporting that they are unable to save global settings for the plugin. The problem is that no one is seeing any errors generated in the ruby console so I am currently at a loss on the exact problem and how to solve it.

Has anyone seen a similar issue and have been able to resolve it?

The code to write the global settings is very simple, an example below:

# Writes Materialsoption Setting @Materialsoption_write_result = Sketchup.write_default "MEDEEK_TRUSS_PLUGIN", "MATERIALS_OPTION", @Materialsoption_newWhy would this stop working on SU2018 running on MacOS?

-

Per the discussion in my previous post, I've shown two H1 Clips both attached to the exterior of the wall. One is oriented with the flanges inward and the other with the flanges outward. Notice the placement of the bird blocking next to the clips. My question is what is the preferred orientation of the H1 clip?

Model can be viewed here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

Based on my discussion with other engineers and architects so far it would seem that the best placement of the clips is on the exterior of the wall as shown.

-

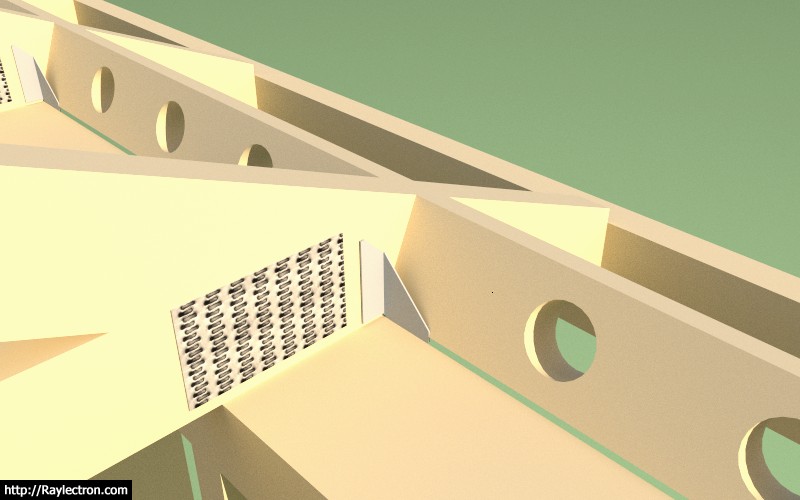

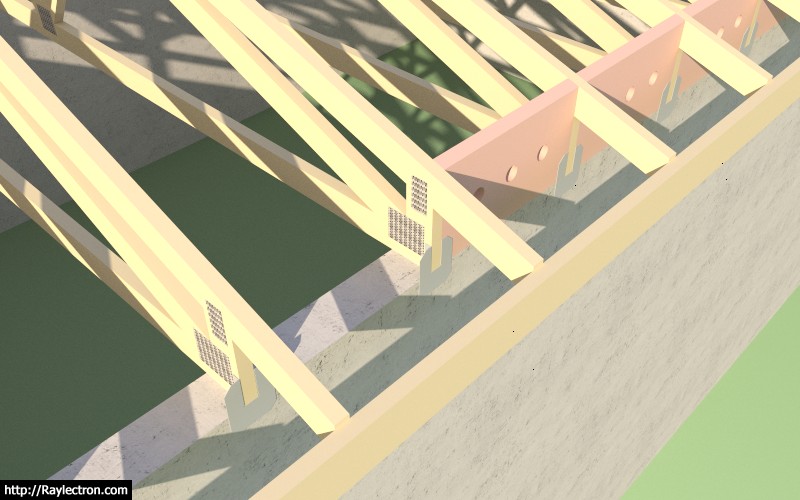

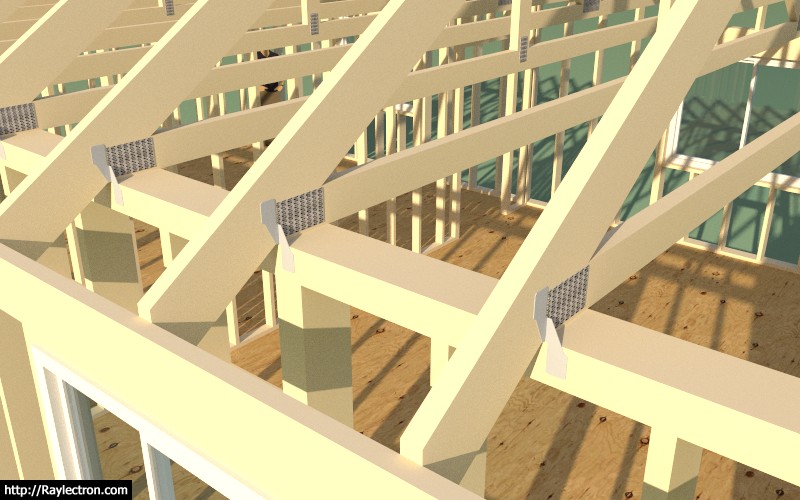

Testing out the H1, H2.5A and H10A hurricane clips:

The plugin is now able to insert hurricane ties. I've currently set it up so that they are installed on the exterior of the framed wall with the flanges inward. Shown below is a Simpson H1 with angled vent blocks.

Here is an example using the Simpson H10A with vertical heel blocks and a raised heel truss connected to a masonry or concrete wall.

Ignore the vent holes in the blocking, I will provide additional options for venting in the near future.

Note that plugin automatically inserts these ties into the truss component, one on each end. The simplified H10A component is based on the official Simpson model found at the 3DWarehouse and is dimensionally accurate but with a much lower polygon count and hence much more lightweight.

Here is an example using the Simpson H2.5A hurricane tie. The upper tab is facing outward by default. The tie on the other end of the truss is positioned on the opposite of the truss to this one.

I will roll it out for trusses first and then rafter roofs at a later date.

I've specifically created simplified, lightweight versions of the hardware, so that the polygon count is minimal. With so many components I think it is imperative that the model is carefully constructed so as to minimize its polygon count and keep it as lightweight as possible.

-

Version 2.1.3 - 12.31.2017

- Enabled hurricane ties for fink and howe common trusses.

-

Medeek Design Inc. - Medeek Truss Plugin Vendors

Medeek Design Inc. - Medeek Truss Plugin Vendors

(design.medeek.com)

List of material suppliers and vendors featured in the Medeek Truss Plugin.

-

Does anyone have some shop drawings of a dutch gable or half hip roof? I am looking at adding in the truss sets for these two variants.

-

The last few days I've been spending some time tightening up the code for the attic truss module. I will be adding in the heel wedge and slider option for raised/energy heels for this truss type as well as bringing it up to speed with other options.

If I get ambitious I will also add in gable end trusses and plates.

-

Version 2.1.4 - 01.20.2018

- Completed energy/raised heels for attic trusses (2 variants: wedge and slider).

- Added floor sheathing and attic gypsum for attic trusses.

- Created a separate HTML menu for advanced options of attic trusses.

- Enabled gable end trusses for attic trusses.

- Hurricane ties enabled for attic trusses.

The gable end trusses for attic truss sets currently do not have any vertical studs as of yet, however the actual truss component is unique and different from the common attic trusses.

I also need to add in some logic for the gable end wall framing which is still absent. I am curious if anyone has experience or examples of this framed out, do you use a single or double top plate? I don't see a reason to use a double top plate in this situation.

Naturally the gable end wall may involve some windows or doors so there will be some overlap with the wall plugin, I am still thinking about how best to integrate the two plugins.

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

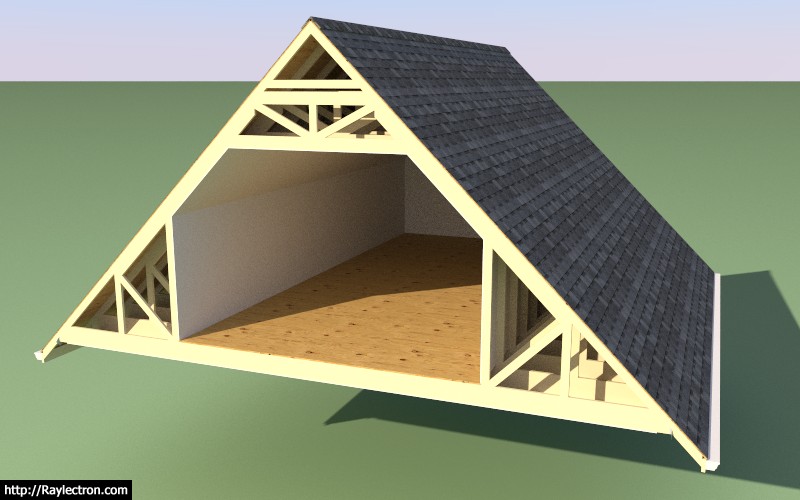

Typical application involving an attic truss over a large open space like a garage.

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

Advertisement