[Plugin] GKWare Cabinet Maker

-

I will dig into that.

For now anyone having trouble can use this - but only if they have a userid and password already.

http://cabmaker32.com/wp-login.phpAlternatively - send me a private message with the userID you would like and I can set you up with an account and a temporary password which you can change by loggin in and change it yourself.

Hope this helps.

-

Ditto on the thanks, Garry. I consider it a privilege. Registered and downloaded the beta last night. No issues with either.

Have a long day ahead but will try and put it through its paces starting this evening. I'll be working in feet, inches and fractions thereof, so it should be interesting. Anything pops it the Ruby console and I'll forward it along.

Phillip

-

I have tested it with feet and inches. The translation is only approximate so I suggest that you edit various sizes.

Here is what I see when I set the units to Fractional inches with a precision of 1/64"

For instance 768 mm converts to ~ 31 1/2"

For easy math you might want a drawer bank with 4 - 8" drawers. So set your cabinet height to 32"Sketchup converts the mm to fractional inches and you get the following

Edit and remove the tilde '~' and it will work better for you.

-

Thanks for the heads up. I certainly don't mind making the change, but in the US market, I can see how that might be a problem. Since you are already aware, I presume you already have something in mind.

-

If you stay in fractional inches then you only have to edit and save these forms once!

I'm pretty sure that if you use decimal inches then there is only a problem if your precision isn't set fine enough.A precision of 0.0001 is sufficient.

In the future I can provide a set of templates that are set up in fractional inches. But why go to all that trouble when users are going to edit material thickness, rules etc.. anyway!!

So - is it really an issue?

Up here in Canada our building trades have always worked in feet and inches. When I built stairs and cabinets I measured up the building using feet and inches. I also quoted jobs using feet and inches. It was when I got to shop drawings that everything goes to metric.

Say I have a 14 riser stair and the total rise is 9' 1 5/8". Say you want 1/32" precision each rise would be 7 27/32". This gives you a total error of 3/16". This might not seem like much but it does throw off a circular stair.

This is equal to 2784.475 mm which works out to 198.9 mm rise per step. This gives me a total error of .125 mm which is negligable.

With cabinets my work flow would include the use of a micrometer to check the thickness of the panels. I would then make an adjustment to the material form and perform a batch edit. The entire material list would then adjust automatically.

Each to there own. Just showing you the flexibility of this plugin design.

One thought I have is to include an automatic parser like I do with my C / C++ programming.

So you could enter formulas like (95 5/8") / 5

and let the software do the calculation for you. Over the years I certainly found this approach very useful. -

When I said, "I presume you already have something in mind.", I was sure you had already thought it through. You don't disappoint. I all sounds good.

-

I have found a few bugs that I am fixing today.

-

If you try Mitered door without a mitered profile system throws an error. I am putting in form validation which will notify you of the pending problem. The same goes for embossed doors (which I haven't completed yet)

-

I'm also putting in some disabling of ignored fields for doors. For instance a plain panel can't have panel profile, stile profile etc. These fields will be disabled when you choose plain panel. This holds true for various other styles of doors.

-

There is a bug for drawer styles. Only square drawer styles are working. I will fix this as well

Also - if anyone is getting any login errors please tell me who you are and we'll see what we can do to fix it.

I am also putting in more intelligent door and drawer validation.

The drawer will change to a square 5 piece drawer front if there isn't enough room for an arch drawer style. And the drawer will change to a plain panel if there isn't enough room for a 5 piece drawer square drawer front. -

-

Whoo hoo!! Going to DL now to a little play.... have been following your thread for a while Garry; really impressed with what you've done so far!

-

Version 1.07 is ready for download.

The fixes that I mentioned earlier are in this version.

-

What do you anticipate the cost of this plugin to be, Garry?

-

Gary I signed up for the Beta and was trying to make my first cabinet. I used all the default dim that were entered in the form, model in mm. I selected a starting point at 0,0,0 then entered 600.00,00 for width and angle. I get one side of a cabinet. I am using Sketchup 2015 on a portable Win 7. This is the error message:

Error: #<NoMethodError: undefined method

copy' for #<Sketchup::ComponentInstance:0xd6ace80>> c:/users/keith/appdata/roaming/sketchup/sketchup 2015/sketchup/plugins/gkware_cabmaker/cabmaker.rbs:1940:incopy_component'

c:/users/keith/appdata/roaming/sketchup/sketchup 2015/sketchup/plugins/gkware_cabmaker/cabmaker.rbs:525:inmake_sides' c:/users/keith/appdata/roaming/sketchup/sketchup 2015/sketchup/plugins/gkware_cabmaker/cabmaker.rbs:1985:indraw_cabinet'

c:/users/keith/appdata/roaming/sketchup/sketchup 2015/sketchup/plugins/gkware_cabmaker/cabmaker.rbs:2444:inmake_one_cabinet' c:/users/keith/appdata/roaming/sketchup/sketchup 2015/sketchup/plugins/gkware_cabmaker/cabmaker.rbs:214:indo_create_cabinet'

c:/users/keith/appdata/roaming/sketchup/sketchup 2015/sketchup/plugins/gkware_cabmaker/cabmaker.rbs:443:in `onLButtonDown'Keith

-

I will check into this - I haven't tested that part out. Been so busy actually forgot that I have that in there.

For now - click x, y where ever you want the left hand front corner of the cabinet and drag in the direction you want it.

I'll fix the keyboard entry part.

-

Sorry Gary I found that I had the Dynamic Components Extension turned OFF.

Keith

-

Thanks Keith,

Version 1.0.8 is now available

- The error you saw was because I was referencing a Dynamic Component method. I've changed the code so I don't do this. You should be able to run cab maker with Dynamic Components turned off. Of course you won't get doors opening and closing and drawers and pullouts animating.

The animation information is store with the doors and drawers. Animation will be available once you turn Dynamic Components back on.

-

The keyboard entry is fixed for angle. Currently Width is ignored.

-

Fixed a smart calculations for drawer and door heights

-

-

I've been asked to add in face frames for the cabinets. How valuable would this be as a potential addition?

-

I've also been asked to add a rule for running a dado in the sides for tops and bottoms.

-

-

New version 1.0.9 is now available.

- Fixed a bug that I caused when fixing the Dynamic Component reference.

Here are some explanations for some of the options:

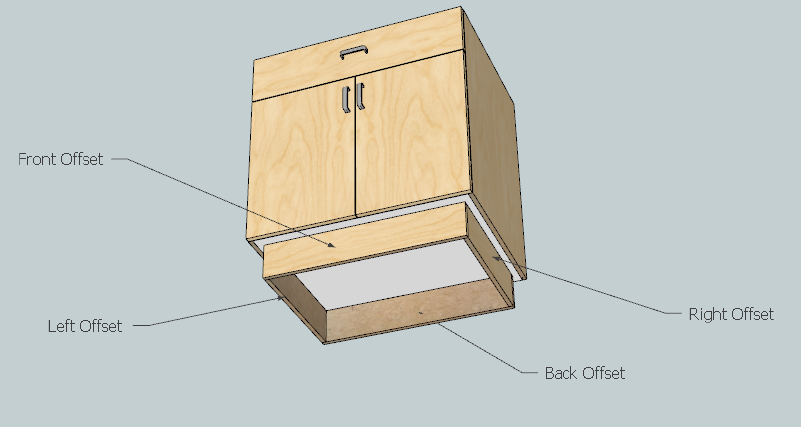

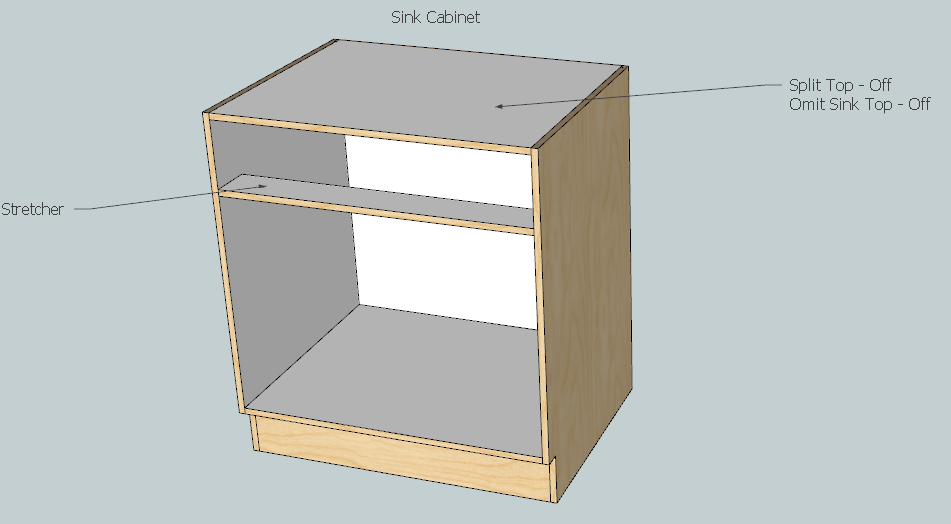

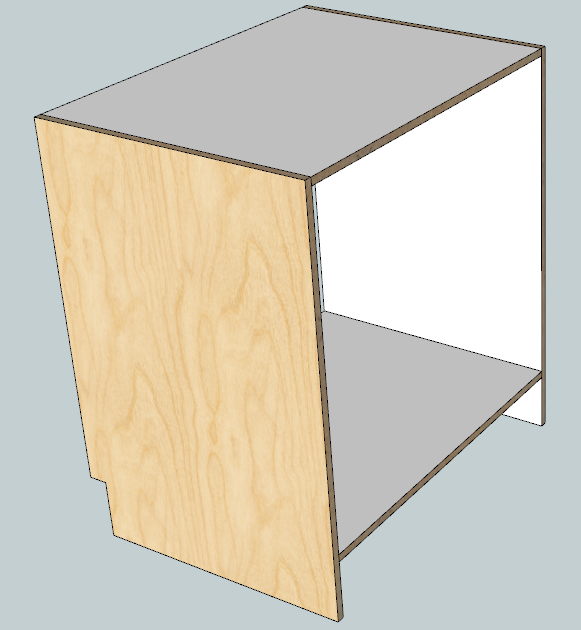

Integrate Kicks OFF

Only Angled and Return cabinets have Back Right Offset

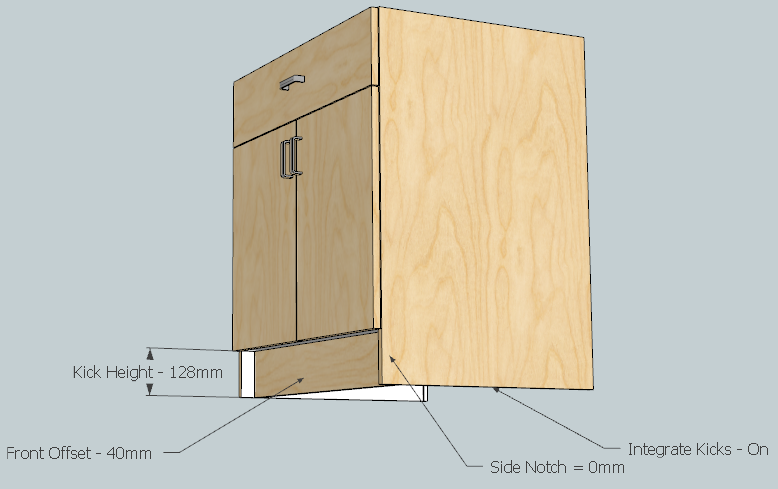

Integrate Kicks - On means the side panels go to the floor. In this case only Front Offset works. Right, Left, Back, Back Right are all ignored.

Side Notch controls how much the Notch in the side panel is recessed. You adjust these independently.

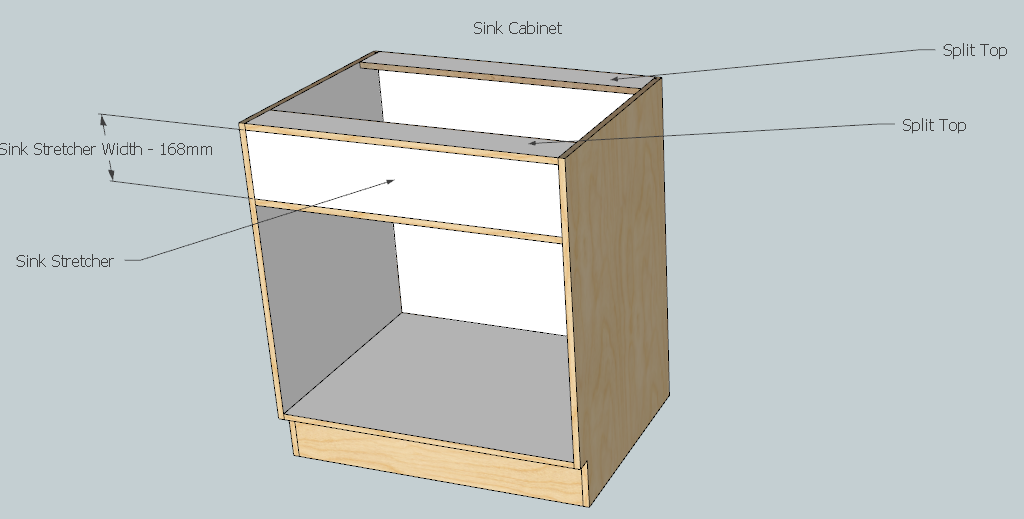

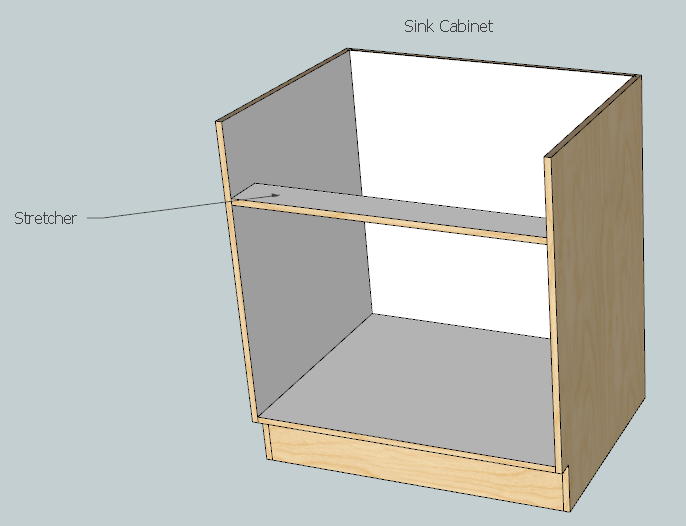

Sink cabinets have optional Sink Stretcher. Set Sink Stretcher Width = 0 if you don't want a sink stretcher.

When there is no Sink Stretcher then the drawer front has a handle and tips out.

Here I set Sink Stretcher Width = 0.

Omit Sink Top = On. This means Sink Cabinets do not have Tops

Split Top = Off. You get a full top.

If you want Sink cabinets to have full tops then you Set Omit Sink Top = Off.

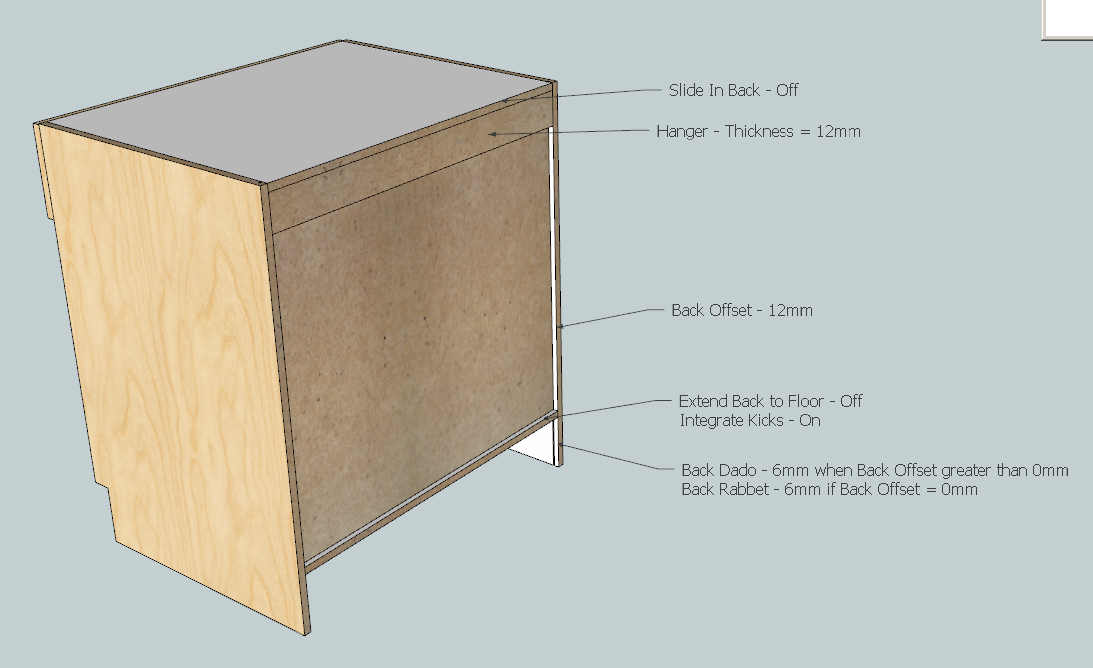

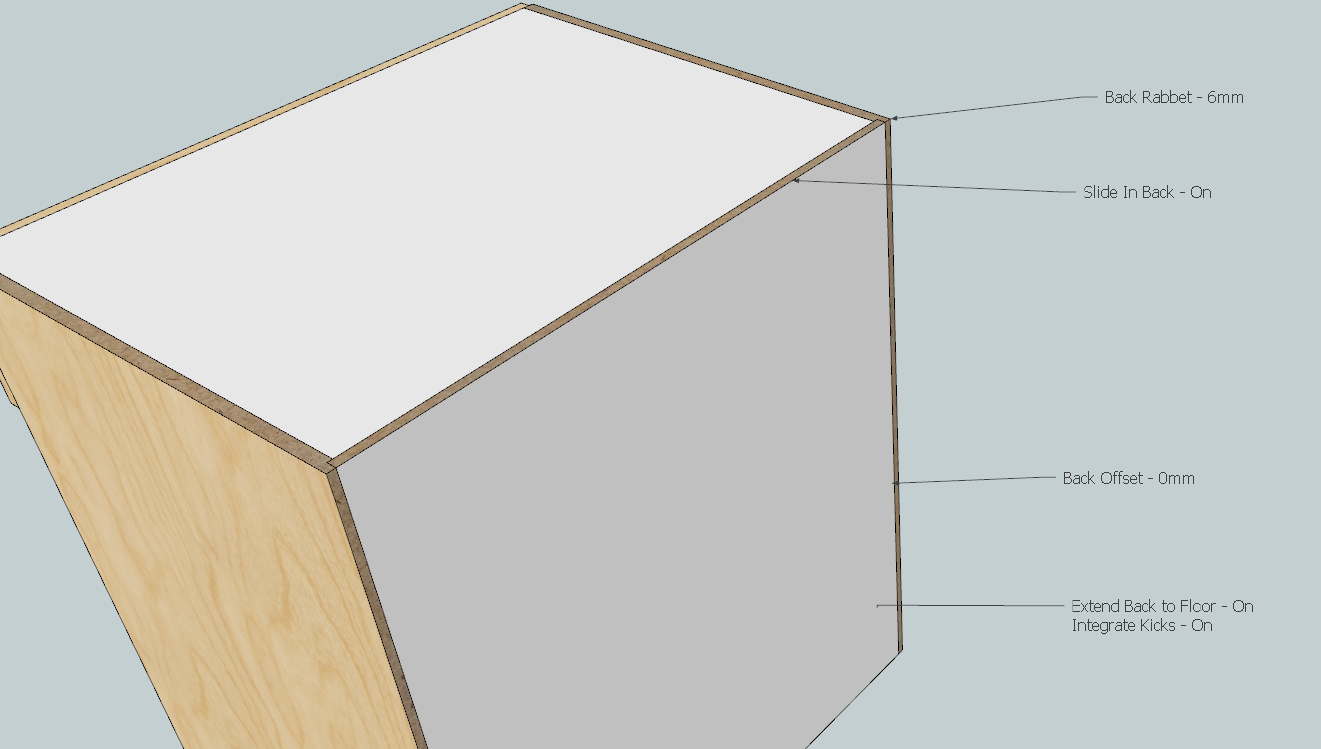

The back is controlled by a number of options.

Hanger is on outside when Back Offset >= Hanger Thickness.

Hanger is on inside when Back Offset < Hanger Thickness.

Back Finished 1 Side = Off. This means both back surfaces are finished

Integrate Kicks = On. Side Panels go to the floor

Extend Back to Floor = On. Back goes to the floor

Slide in Back = On. Back goes to top of cabinet and Top stops at back.

Skip Back - On. There is no back, no Back Dado / Rabbet, no Back Offset

You can still turn on Finished back which is applied to outside of cabinet.

-

I've got the new embossed door working.

An embossed door is like an MDF door - the profile is routed in and the back side is flat.

These doors may be painted or have a thermoplastic finish in a wood grain texture or solid color. -

Fantastic cabinet plugin. When I used designcad 3d for my home shop I wrote a macro to design kitchen cabinets for my project to build my daughters cabinets so I at least have a idea of the complicated nature of the program and I only had to provide options to please myself.

-

The book I use to design cabinets suggests for toe kicks to make 1 frame for each bank of cabinets or to use the adjustable legs on each base cabinet. Any plans to offer this option.

-

For my grandson's kitchen I need a angled sink cabinet. This can be built by editing the cabinet and removing the drawer and hardware but you might consider this option.

-

On my portable pc I need to re size the input form to see all the form but found no way for the re-size to be remembered by the program. Is there a method of dealing with this?

Keith

-

-

Keith,

I too have many memories working in designcad 3d. My first version was for DOS and if memory serves me it was like version 2. I spent some time a couple of years ago doing some of this work in Basic CAD - but I gave up as there macro language wasn't really suitable for this kind of work.

I used to build cabinets without the kick, base, plinth (whatever you want to call it. I would lay out the base and build what we used to call ladders (I gues they kind of looked like ladders).

Today it seems that more and more cabinets are going modular. I can certainly add in an option to omit kicks. Adjustable legs often have a clip or a way to attach a front kick board right to the leg. I'm not sure that it would be necessary to draw the legs. Maybe cabinet makers would like to see that, I'm pretty sure that designers and architects would see that as too much detail.

Modeling is all about trade offs when it comes to detail and overall model size. Do we need to show every hole for adjustable shelves, each and every fastner like dowels, confirmats? And what about the hinges and screws that attach to handles? This is a can't please everyone situation. Having said that, I'm most willing to consider options when many users are in agreement that the option is needed and makes sense.

I can certainly add in an angled sink option. I've also been asked to add in tall cabinets for pantries and built in stove cabinets. Then there are curved cabinets. This I will do once I complete some documentation. I know I need to spend time putting together a visual manual and quite liekly a set of utube videos.

Have you tried the option to use small fonts? I've included 2 style sheets, gkware.css and gkware_small.css. Feel free to edit a style sheet. You can adjust font sizes, back ground color etc.

But if you do please remember to save a copy of your changes otherwise your changes will be over written during your next upgrade.For simplicity you can tell cabmaker to use gkware_small.css by setting small fonts to true.

In closing - how do you find the overall laytout of the web forms? Are they straight forward? Are any parts confusing?

-

Thanks to Igor who found an issue with Drawer Boxes and Pullouts. When you turn off the Door And Drawer Fronts layer they disappeared.

I will nest the door parts and handle inside a new group. This way the new group belongs to the Door And Drawer Fronts layer.

What is nice is that the drawer boxes animate even when the new Door and Drawer Fronts are turned off!

Advertisement