Problem with RepRap Thermistor

-

Hi, some time ago, I build a RepRap Prusa. Everything is ok until a few days.

I used to print with PronterFace and also use Marlin as firmware, but I get an error: the thermistor mark 0 degrees. Change the thermistor, check the wires twice, check the conections, twice also, and everything seems to be ok, but still gives me the same error.

Is any other software that I can use to print?

Thanks in advance. Regards,

Edgar

-

Hi Edgar

Thermistor mark 0 degrees mean no power to heating coils

bad switch from a driver lines or the feed data stream missing

use a volt meter to find the break ( you can eye in parts for melts signs or solder legs opens and ribbon cables can open up on you too.)

moving parts can make/break on you also.

did you have a software changes

need more info to help you more.

or

software exporter for your machine may be limited

check with RepRap Prusa

sorry for the wait

-

@dukejazz said:

Hi Edgar

Thermistor mark 0 degrees mean no power to heating coilsExact, the extruder don't heat

@dukejazz said:

bad switch from a driver lines or the feed data stream missing

use a volt meter to find the break ( you can eye in parts for melts signs or solder legs opens and ribbon cables can open up on you too.)

I already use a voltimeter for check twice the wires.

@dukejazz said:

did you have a software changes

Change PC

@dukejazz said:

software exporter for your machine may be limited

Any other software like Cura o Slic3r?

@dukejazz said:

sorry for the wait

No problem, thanks for your attention.

@dukejazz said:

check with RepRap Prusa

I already search in reprap forums but I can't solve my problem.

Regards

-

Is this the system unit you have

RepRap 101: Installing a hotend thermistor with silicate-based cement | ZennmasterM

- you says wire paths are not broken or no unsolder legs to IC and computer were change out or check and software is ok and no fall off SMT parts.

now testing a Thermistor ( bad feedback of Thermistor will shut down system)

you can test Thermistor with outside heat sorce on it (in and out of systems) using the omh meter settings

Thermistor for measuring/controlling temperature | RimstarOrg

if this change with temp then the heater source or coil filement is not working or not on

(somthing is over heated and open or burn out)

if the modulator signal is working to the heating sourcr then it's the power thansitors or heater elements.

(now use diode setting of meter)

Your power thansitors maybe open or shorted out. or/and also may took out a system fuse or circuit breaker trip or a cheap resiter burn open.

need info - wait time for your finding.

note: bad parts you can see vent holes or melts or cracks

my bet its the heater element open up on you. heater coil or laser can go out with time.

-

Many Thanks Dukejazz! I take a look to the links and comment to you later.

Regardas

-

Hi Dukejazz, sorry for the late.

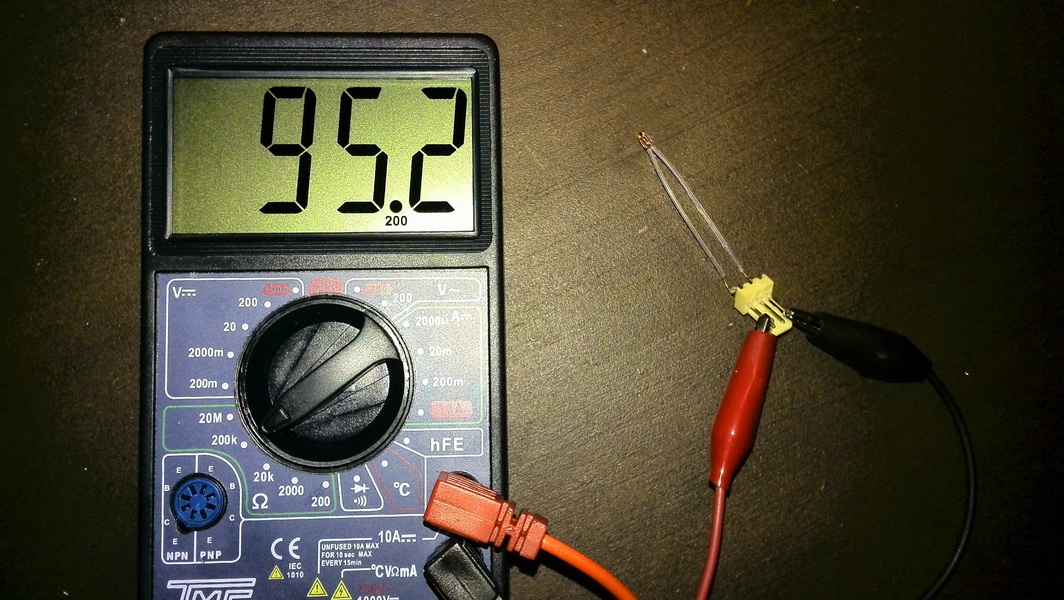

I messure the direct on the thermistor, a 100k epcos https://ultimachine.com/content/thermistor-100k and show me 95.2

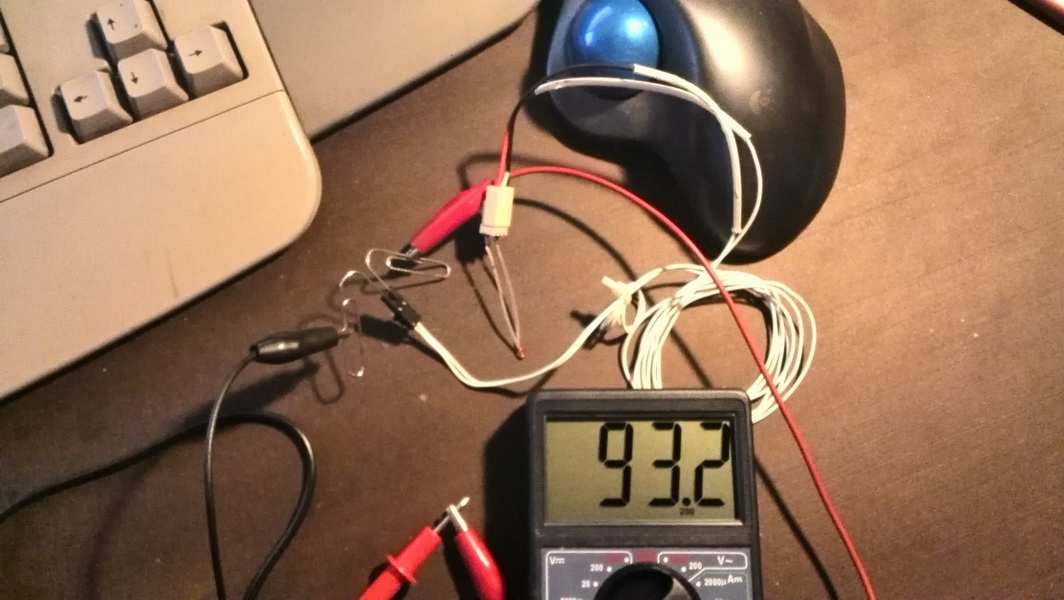

Later, I messure at the end of the cable and show me 93.2

It's ok that numbers or or should show 100.

I read, in some place, that 90-95 should be a good lecture.

Also, I use other type of thermistor, (don't have espec for that kind of thermistor). When I connect the other thermistor (not the 100k epcos), Pronterface (aka Printrun) read 245C that also is not right

-

thermistor value will change with temp (hold a ice bag near it to see if you meter have any change in reading)

if you have change with tempiture then thermistor is not broken

the thermistor need good contack to nosle ( tape, glue, screw down or cemented greesed ) no contact mean 0 deg c to you machine

I readed yesterday you need to keep nosle head clean ( with a clearner )

why because the heat scorce iron needs to conduct heat to element rasin to melt

You have to have both electron flow to nosle iron and iron heat tranfer to element rasin and then to thermistor to give a feedback to keep machine runing.

-

Hey! Thanks, I put my fingers in the thermistor and change the value. Now, i am sure the thermistor is ok. I think it's going to be a software problem.

Advertisement