Convert real world curves to Cad, help.

-

Hi guys,

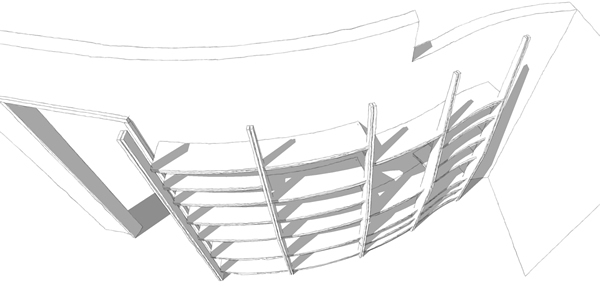

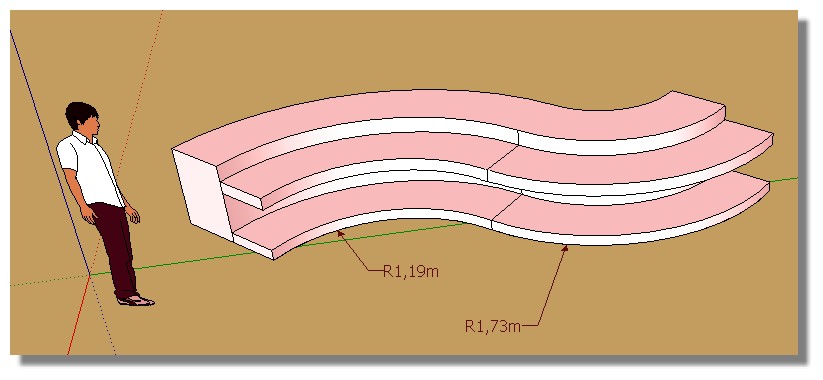

I have to fit a furniture piece to a curved wall. Basically its a bunch of shelves.I want to get the shelves cnc'd. So I need a dxf.

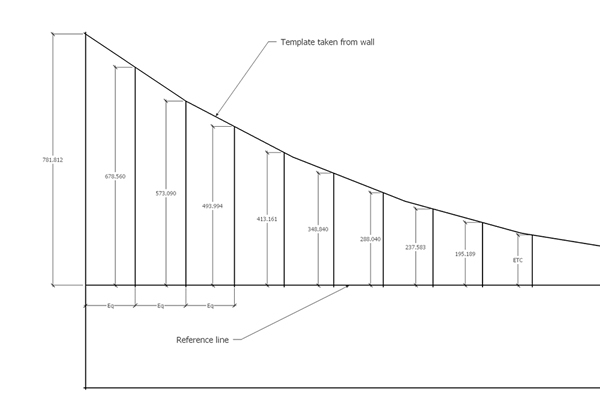

I can take an accurate template off the wall, but then the only way I can of think of to get it into Cad is to laboriously and very accurately take measurements from a reference line along the curve. (See drawing)

Can any of you guys suggest a more accurate and elegant solution?

Thanks.

-

In my cabinet shop we would scribe things to get a good field dimension. But I don't know about getting it into cad. you might consider taking a picture of the template from above. or scanning it piece by piece.

-

Some arcs circles ? So you will have some radius ?

-

@unknownuser said:

Some arcs circles ? So you will have some radius ?

Well no, not really, the builders followed the plans, but this is the real world, I have to fit my unit to what is there.

I have been thinking about it all day, I'm pretty sure it has to measured carefully on site and transferred to cad.PS: cooking a render as we speak...

-

don't very well understand the problem

you speak about arcs or circles who are not real circles with dxf export ?

Maybe the Pro version of sketchup has a DXF or dwg export with real circles ? (not sure)

Else maybe use some Nurbs Modeler ? Moi

or very low cost Viacad 2d/3d v9 79$ 99 (top page + use code) I believe the best for the price/possibilities! (you can import SKP file inside )

(you can import SKP file inside ) -

The best and most accurate way is to plot out the points as you mentioned. Afterwards, I would plot it out full size and see how it fits, make any adjustments, then do it again. It's waaay easier and cheaper to do this on paper than wood.

-

maybe in the not-too-distant future, we'll have an affordable and accurate means of doing this via 3D scanning but i don't think that solution exists just yet..

plot away

-

Any approach you select the issue of frame of ref calibration for your measurement system must be addressed. At my previous company we used: Photogrammetry ; a cluster of 4 theodolites mounted on piers with a invar surveyor chain 50' long laid on floor to calibrate to make surface contour measurements. Even state of art of 3 d scanner are getting to large area scans

Those first two above would be too expensive for you but the point I am trying to make is there are companies that do such measurements and few phone calls may help at least with possible ideas. I have no ref for you at this point. Been retired too long

As a home owner was thinking about a large pin board, like small ones used to meas molding contours etc. Frame of ref probably rented laser. Think you are looking for stable relative meas not absolute.

Just some crazy thoughts. -

Baz I think you are on a hiding to nothing trying to get the shelves machined to fit flush. It doesn't matter how many points you measure you'll always miss a high point or low point somewhere along the way and the curve can throw one way or the other causing gaping or binding between the shelves. Not to mention, if you manage to follow the curve perfectly if it isn't a perfect curve it will look awful. I've been involved in many installations of professional constructed curved walls, they are never to plan and never even.

To options spring to mind for me that would make like easier for you.

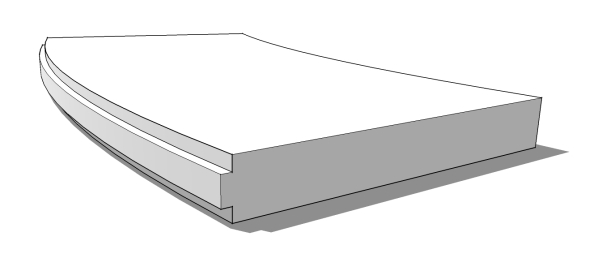

Use uprights at the back to shift the shelves forward. This way you can use your template to calculate a suitable radius that will fit within tolerance and look like a smooth curve. This gives another benefit of having a place to drop the odd electrical cable down the back.Or if the flush look is critical, use a false back on the shelves to look like it is the wall. This way you can construct the full unit to fit in the workshop and it's only important to get an edge or two spot on so it appears built in.

Anyway, just random thoughts because when god made curves it was so he could laugh at as when we tried to build with them.

-

Hey thanks for the replies.

You have given me two great ideas;Use a handheld laser to plot the points along the template board, this is essentially the same as the hand method but takes out several opportunities for error. ( And I've been looking for an excuse to buy one:)

Box's idea of the false wall wont play but the idea of a gap between the wall and the unit is a ripper. The shelves are 32mm thick, so I could run a rebate top and bottom on the back edges to give a nice shadow line. This would hide the lumps and bumps.

This also allows me to hopefully use pure arcs as Pilou was mentioning, if the wall isn't too far out from the design.Thanks.

Baz

-

And if you only have meat at the fixing points therefore reducing the points of contact, you get away with a multitude of sins in the wall finish.

-

@box said:

And if you only have meat at the fixing points therefore reducing the points of contact, you get away with a multitude of sins in the wall finish.

Even better!

-

Thought I would show you the installation, (crap phone photo), all went well, ended up using a 'false' wall of 4mm mdf behind. With the dark colour it's almost invisible.

Thought I would show you the installation, (crap phone photo), all went well, ended up using a 'false' wall of 4mm mdf behind. With the dark colour it's almost invisible.

The curves matched the existing wall very well.

Cheers

Baz -

Looks great Baz...

-

Excellent solution there Baz, wish I'd thought of it.

-

-

-

Well roll me in beer batter and call me a Battered Sav, so I did.

-

@box said:

Well roll me in beer batter and call me a Battered Sav, so I did.

That might need translating for the the non-aussies here

I await your reply in anticipation...

-

I'm afraid Baz even a translation would be over their heads. We do have a certain uniqueness to some of our local delicacies.

Advertisement