Flipping Crazy

-

So you don't use a replacement mehod

Yes ...but how do you make when you have a little hundred of bolts in any orientation to change ?

PS For me its' save as V6 or V7 for read the files

-

Hi Dave...

Forgive me if I already asked you, but could you remind me of the 'fewer' steps you use

.

.I've had so much correspondence around this topic with so many people on different forums, I've lost track

Bob

-

Piloe,

Re "So you don't use a replacement method". Sorry to say, but I was going about this all wrong. I was using BoltMaker as a way to automatically create a bolt that would resize itself according to the dimensions of the target. I thought that by simply replacing the BoltMaker bolt with mine that it would be very easy to do. Sadly, I was wrong.

I do thank you for your efforts.

Bob

-

Bob, there are links on the first page of this thread. No plugins required the way I do it.

I'm curious about your procedure. You are locating the bolt so its center is aligned with the center of the block component. Why do you put a fastener in a single piece? Wouldn't that fastener be used to hold two parts together? And if that's the case, you don't want the center of the bolt located at the center of a single part, do you? What happens when you have a pair of bolts to locate on the part. Both of them can't be at the center in the part.

I would locate the insertion point for the screw in your example centered at the top of the head and place the screws at points on the surface of the part. These would be the points you'd identify in reality instead of points inside the part.

And with gluing, the bolts drop in easily in any orientation desired.

The only plugin used in the creation of the model in the video was to drill and counterbore the holes for the bolts. Everything else was done with native tools. It would be trivial to adjust the lengths of the bolts as needed so I didn't show that.

-

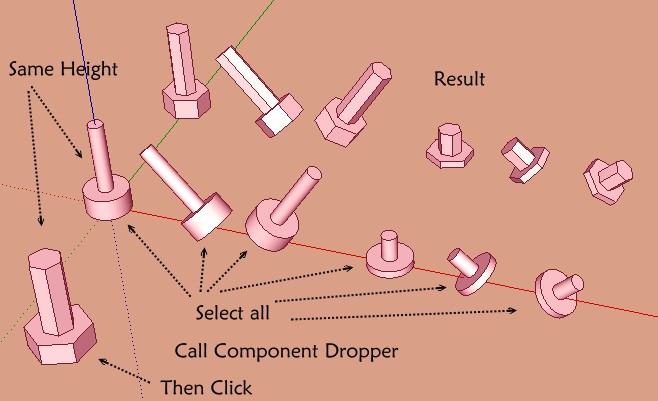

Maybe you can also look at Component Dropper by ThomThom

-

Hi Dave...

This is an excellent video tutorial. Thank you so much

. I would prefer your solution to mine if I can get it to work on BoltMaker XII output. You see, BoltMaker automaticaaly sizes the bolt to match its target.

. I would prefer your solution to mine if I can get it to work on BoltMaker XII output. You see, BoltMaker automaticaaly sizes the bolt to match its target.Just one question: was the bolt you used created with BoltMaker XII and if so, did you manipulate it's axis in any prior to gluing them?

To answer your question "Why do you put a fastener in a single piece?".

Answer: To illustrate the 'flipping' issue I was experiencing when using BoltMaker XII. I totally agree that a single bolt in just one piece would serve no purpose

.

. -

@bsintzel said:

Hi Dave...

This is an excellent video tutorial. Thank you so much

.

.Ah. Thank you. I'm glad that was helpful.

@bsintzel said:

I would prefer your solution to mine if I can get it to work on BoltMaker XII output. You see, BoltMaker automaticaaly sizes the bolt to match its target.

Just one question: was the bolt you used created with BoltMaker XII and if so, did you manipulate it's axis in any prior to gluing them?

No. I didn't use any plugins to create the bolt. I just drew it manually. In this example I made the screw, washers and nut as separate components and made a nested component of them. When I made the nested component I set Gluing to 'Any' and clicked on the button to set the axes. I then placed the axes at the top of and centered on the head. It took little time to do the whole thing. I think I spent more time looking up the real dimensions for the head and socket than drawing the components. BUT I don't ever have to look that info up again.

Since the screw, washers and nut are separate components, I can easily get a parts list from the model if I want it.

@bsintzel said:

To answer your question "Why do you put a fastener in a single piece?".

Answer: To illustrate the 'flipping' issue I was experiencing when using BoltMaker XII. I totally agree that a single bolt in just one piece would serve no purpose

.

.That makes sense. It seems to me that the boltmaker plugin currently creates more problems than it solves and forces you to be inefficient as you are working.

I now have a 1/4 in. socket head cap screw that is designed to sit with the top of the head flush to the surface of the part. It would be easy enough to edit its length or modify the location of the insertion point so I can have it insert with the washer on the surface. I could eliminate the washers or change the nut to a locking nut or whatever and do it all with only the native tools.

-

Dave R,

I 'really' liked the plugin you used to counter-bore. I design folding furniture that I ultimately make for myself so the counter-bore plugin you used would be a real time saver.

I found a suite of woodworking plugins https://sites.google.com/site/wudworx/plugins-and-tools/wwxboardmaker) and purchased the Wudworx Library Version 2(includes BoardMaker Pro, Dovetails, M&T, and Drill plugins).

I'm not sure if it's the same plugins you use. If so, you should get a kickback for semi-advertising their plugin

I can't thank you enough for the amazing support you've provided.

Warm regards

Bob

-

Bob, that's the plugin I used for the holes. I don't suppose you have much need for dovetails on your folding furniture but the Wudworx Dovetail plugin is perfect as is the M&T plugin.

I'm glad if something there was helpful.

-

Dave R,

Dovetails on folding furniture? lol...your right about that. Actually, I'm about to purchase a dovetail jig to add to my shop so the dovetail plugin is a perfect complement to it.

Bob

-

What dovetail jig do you have your eye on?

-

Dave R.,

No particular product as yet.

When it comes to woodworking tools, I'm pretty serious and somewhat picky about what I buy.

However, I've only begun my research into dovetail jigs. I have no 'hands-on' experience with them so I'm taking the time to learn as much as I can before buying anything.

We have a couple of places here that I like to shop at (Lee Valley and Busy Bee). They employ experienced craftsmen that actually use the tools they sell. Better yet, they offer free seminars to prospective purchasers. Can't beat that

Have you had different experiences with dovetail jigs yourself? If so, any tips about what constitutes a good dovetail jig would be welcomed.

Bob

-

I'll send you a PM. We've already dragged this thread off topic.

-

Seems cool tool!

No glue is necessary ?Cool this one

-

Pilou, you might be able to get away without using glue but normally a dovetail joint is glued. The joint is from the days when glue wasn't especially strong, though and it makes a great corner joint. These days, even the most common glues are stronger than the wood. From a practical standpoint there are easier joints to make and for simply joining two pieces of wood, a dovetail joint isn't a requirement for a strong joint. Dovetails can be elegant if made correctly or they can be ugly. There's no point in making dovetail joints if they are going to be fat and ugly.

-

Thx, amazing wood's world!

Advertisement