Not solid after scaling

-

Hi folks

I've been working through learning sketchup and decided to apply some to a model that I want to have 3D printed.

Its a 1920s gravity gas pump. I've modelled the main body so far and wanted to test its properties. I built it in sketchup at 1:1 scale as I know that using curves at small scale sizes can have issues.I then ran solid inspector plugin and ran a .stl through netfabb (free version) and that all came back all clear with no holes. So I thought that I would scale it down (in this case its scale is 1:48) once scaled down to the correct height, I thought I'd run it through solid inspector and netfabb at its new size, however now its showing 4 or 5 errors? I have made the model to quite tight tolerances in certain places, but these were in line with the minimum dimensions that Shapeways require for their FUD material.

Would this be down to the limitations of sketchup at such small sizes or is it a real error that'll need fixing? I have uploaded the pump to shapeways website and it passed their upload tests, but that doesn't always mean it'll print correctly!

I've attached the 1:1 watertight file and the 1:48 error file

Thanks for looking

Dave -

There are some issues with the full sized pump, too. I fixed them and made a scaled down version of it in the same file.

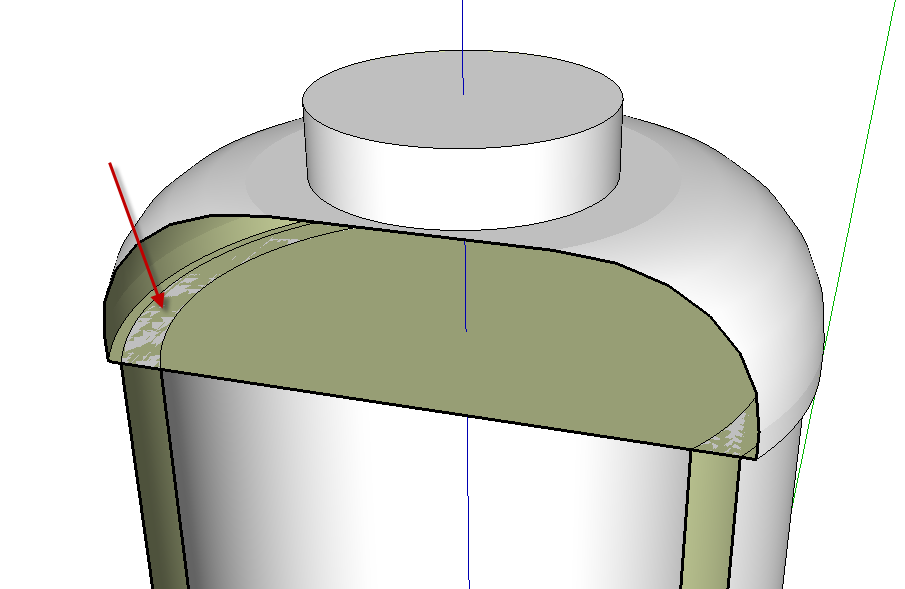

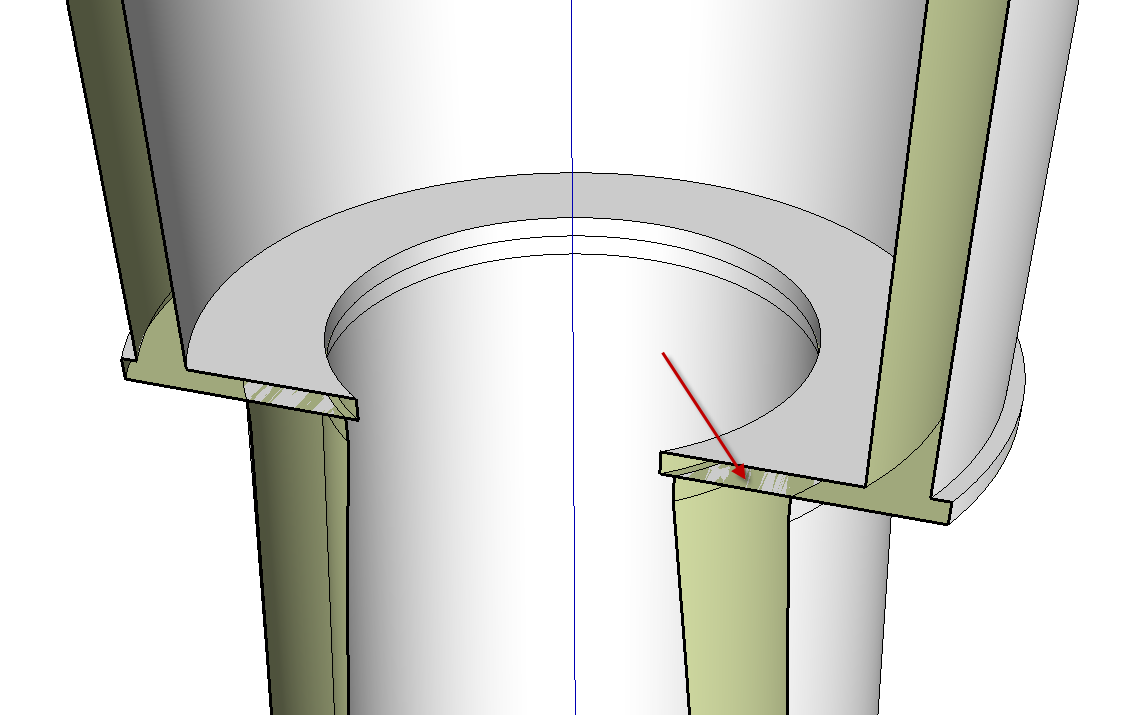

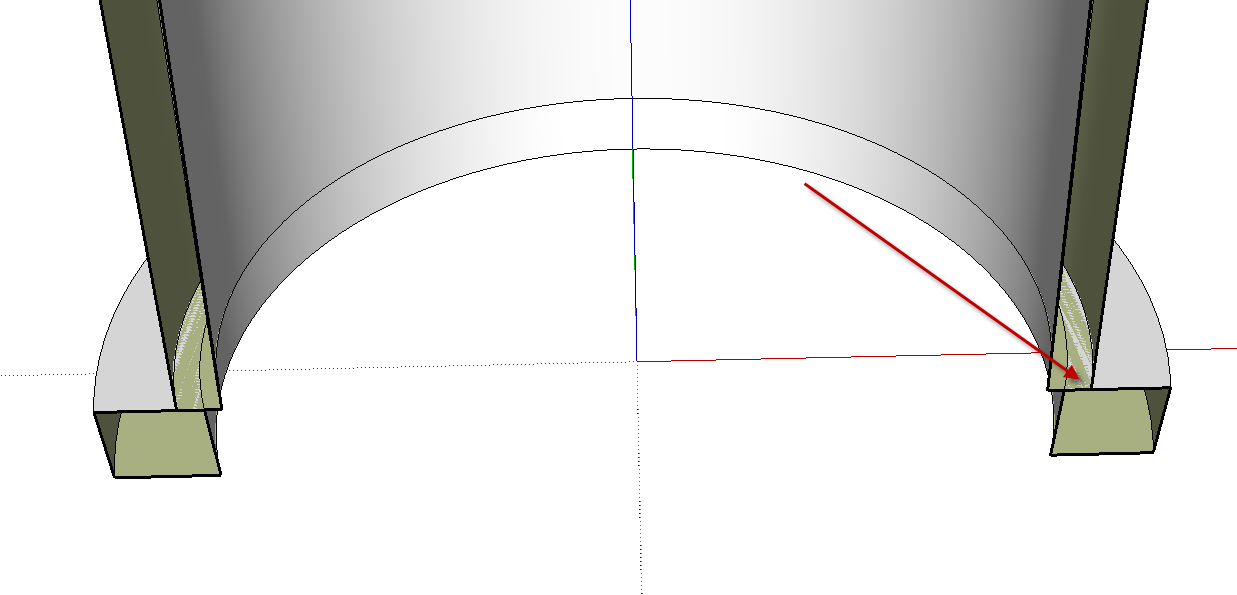

A good way to to check is to make a component of the model and see if SketchUp reports it as "solid". You have some internal faces that need to be removed. See the first three screen shots.

They're not only internal faces but the sort of mottled look indicates there are two faces in the same space. The mottle look is referred to as z-fighting.

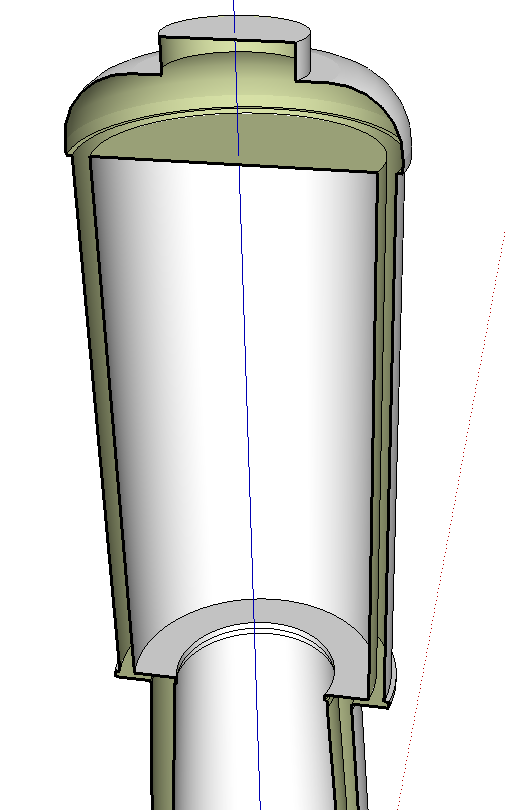

After clean up the pump shows as solid and you can see those internal faces have been removed.

If you are wanting to make this as three separate pieces, you would want to make three separate components and possibly different SKP files for printing. Do you intend for the glass reservoir to be printed as transparent?

By the way, I think you would find it much easier to draw things like this if you turn off endpoints, set precision higher (1/64") and turn off Length Snapping.

If this is to be a single piece when you finish, you could have drawn a section profile and used Follow Me to make it 3D and for no bigger than the final model is, you probably don't need 108 segments in your circles.

If you'll be doing much of this you'll probably find the following Plugins useful.

ThomThom's Solid Inspector.

TIG's Solid Solver.

Advertisement