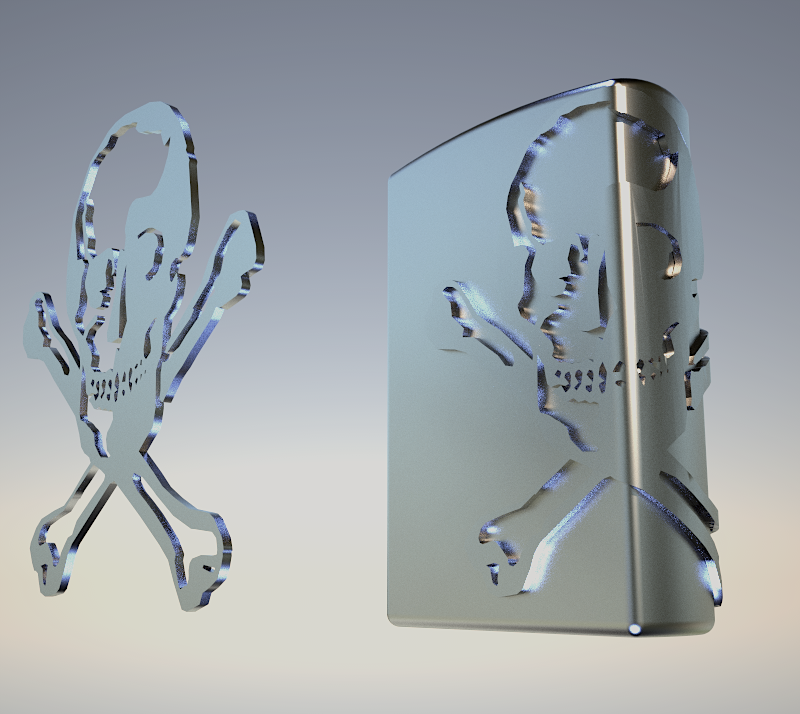

Zippo Lighter

-

ok heres my suggestion, and it worked for me, after ou get your shape bended stretched version move it up to the original and match up on each other, note where the stretch/bend takes place and slice the original into too parts on that line, with the left side rescale it to 1/4 sizeand reconnect the original, now it may look wrong but shapebend it again and theres your result

-

Not sure if I understood you right but what I did still made no difference.

-

I tried this with Fredoscale radial bending. There was no stretching BUT:

- difficult to get close fit to the bend. Won't be exact

- takes several steps and each processing is slow.

- you have to split off the last part and bend it separately then re-join. (when radial bending begins to bend back, it affects the parts you don't want bent)

- There were some faces lost in the last bend I did that needed fixing.

- wonder if it is appropriate for 3d printing

Othere suggestions.

- the skull outline may not be suited to what you are after. Try a simpler outline (less vertices).

- remove the the back face before bending.

- Making the lid joint is going to be a chore. You might do that before bending.

- further rounding of edges. IDK if you have to do it, but I tried and failed.

-

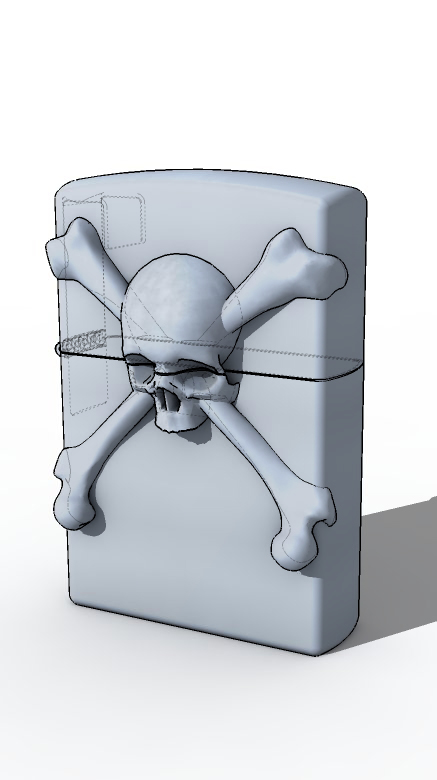

Ok this is my finished design, all are solids but I'm having trouble cutting the lines indicated in the drawing. I just wondering if my computer is to slow or am I doing something wrong?

Thanks Kurt

-

Pretty complex. I don't think my computer can handle that. I tried making the two cutting planes in a solid and trimming the skull= crash.

EDIT: this is sort of a reminder to quit smoking. Right?

-

@pbacot said:

Pretty complex. I don't think my computer can handle that. I tried making the two cutting planes in a solid and trimming the skull= crash.

EDIT: this is sort of a reminder to quit smoking. Right?

It crashes mine too, the quit smoking thing was funny!

-

@pbacot said:

Pretty complex. I don't think my computer can handle that. I tried making the two cutting planes in a solid and trimming the skull= crash.

EDIT: this is sort of a reminder to quit smoking. Right?

Crashes for me too

-

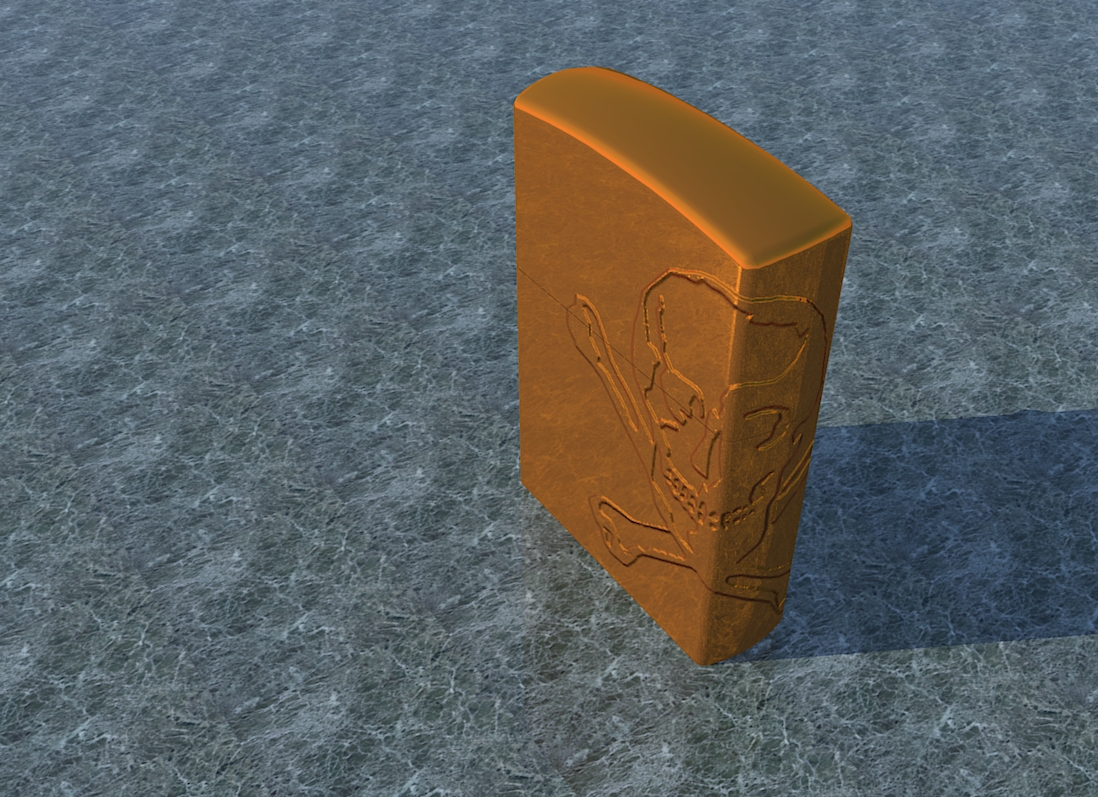

I gave this a try using Kerkythea ( I am trying to learn Kerky). I basically texture mapped the skull and bones image onto the lighter (I may have messed up the hierarchy in the process). In Kerkythea I converted the diffuse map to a bump map and added some metalic quality where needed. Not very easy but doable. Having the skp file you can map any kind of image onto the lighter.

-

@oganocali said:

I gave this a try using Kerkythea ( I am trying to learn Kerky). I basically texture mapped the skull and bones image onto the lighter (I may have messed up the hierarchy in the process). In Kerkythea I converted the diffuse map to a bump map and added some metalic quality where needed. Not very easy but doable. Having the skp file you can map any kind of image onto the lighter.

[attachment=0:3t3kskt2]<!-- ia0 -->skulzippo.jpg<!-- ia0 -->[/attachment:3t3kskt2]Thanks Ogan, will try it out but think I've settled with a different design.

-

That is a nice simple solution, but I believe the original idea was to be able to cut it with a 3D printer which wouldn't work with a rendering.

Has anyone tried to map the skull on to the lighter, then trace it using draw-on-face plugin and then extrude with Joint Push Pull tool? Just a thought.

Rob

-

@rspierenburg said:

That is a nice simple solution, but I believe the original idea was to be able to cut it with a 3D printer which wouldn't work with a rendering.

Has anyone tried to map the skull on to the lighter, then trace it using draw-on-face plugin and then extrude with Joint Push Pull tool? Just a thought.

Rob

I tested that some. It could probably be done with a simple design. I think the original post design could be recreated in 2d with very few vertices. Add more detail if needed after "mounting" on the lighter.Might get hung up with too much detail. But the design has changed since then.

I have not used TOS much. It would be great if the drawing could be transferred from a drawing on a plane to the surface. That would be a great addition to the tools if not already there.

-

The skull is not the hard part, IMO it's the edges that look filed that poses the biggest obstacle.

-

-

Finally finished and sending it to shapeways to get printed. I'm excited to see how it turns out!

-

Awesome, Kurt!

What material did you order it in?

-

@d12dozr said:

Awesome, Kurt!

What material did you order it in?

White Strong & Flexible Polished for now to insure everything is right, later on maybe something a little better.

-

great job!

How did you end up cutting the lid joint?

-

@pbacot said:

great job!

How did you end up cutting the lid joint?

I made lines where I wanted it cut at and intersecting with faces inside a group. By the way it took for ever to get back to a solid!

Advertisement