Anyone have experience with this roof membrane system?

-

Discovered Neptune Coatings WetSuit roofing membrane system today: http://neptunecoatingscorp.com/. Thinking it might be a waterproofing solution for the complexly curved roofs I'm developing. http://dws.editme.com/

Wondering if any of you folks have experience with it?

Thanks,

Fred

-

I am in the process of buying a house with an aging roof membrane. I got the seller to rebate about half the cost quoted by a roofer. As you come up with roofing solutions please pass them on to me. Neptune seems like a good product, but they don't look like they sell on the retail level.

-

Without digging too deeply, this appears to be a modified rubber, spray applied, and cured in place. The concept has been around for over 40 years, if not longer. In the end, no matter the membrane system chosen, it comes down to the installation and the unique characteristics of the roof you apply it on. The more dependent the product is on near laboratory conditions, the more likely will be failure. I have observed that most problems do not occur within the open field of a roofing membrane, but where pipes penetrate, or flagpoles, or where the satellite TV man dropped the CMU blocks that hold down the framework or where roof meets wall and eaves. The most extreme micro- environments are right overhead. Nature has all the time it needs to slowly erode your shelter while you are not looking. I noticed that this material can be used as a waterproofing membrane under a roof garden. Probably the best thing for it. Because it is completely concealed by a sacrificial, naturally rejuvenating layer of soil and plant materials. If the deck is concrete, this is not waterproof either. It just takes longer for the water to penetrate. Maybe all of the above comments have been answered by the product you ask about.

One other thing about single layer polymeric roof membranes. If they do not heal themselves upon puncture, it is often very difficult to locate the actual point of entry of the water. -

For complex organic shaped roves you should probably find a really good panel beater and a really good welder and do a metal roof.

Oh, you wanted an economically plausible answer? Don't ask a timber-frame house builder...

-

I don't know anything about the membrane but I'd love to hear more about your curved roofs.

-

Thanks for the replies.

Roger. I'm going to contact the company next week. I'll let you know what I discover.

mitcord: Thanks for the perspective. If I used the membrane it would be as the waterproofing layer for a green roof.

tim: Love the idea of a beautifully crafted metal panel roof, but, as you note, that's for a different economic class than mine.

Krisidious: Been working on the curved roof concept for a long time. See this 2008 thread here on SketchUCation. http://forums.sketchucation.com/viewtopic.php?f=81&t=8723&start=0 After 30 years working in schools I'm taking a gap year and working on a number of projects, including moving forward with the curved roof ideas. I'm taking classes up at Yestermorrow, a funky design/build school in Vermont http://www.yestermorrow.org/ with that goal in mind.

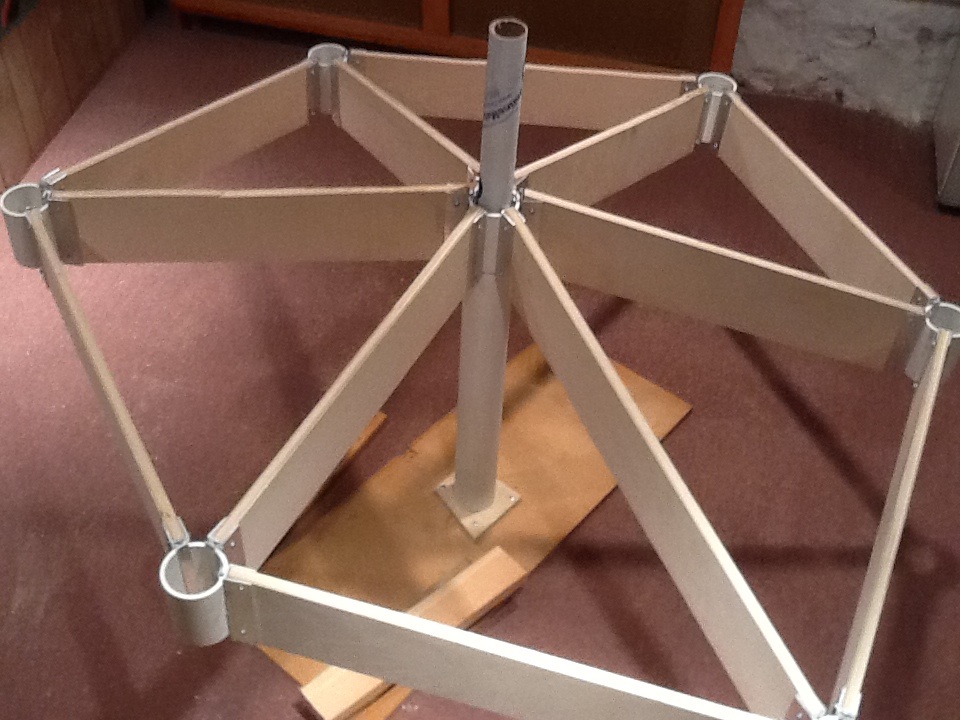

I've made a lot of progress, but it is a long process. I built the prototype in the images below in the last few months. The metal joist hangers are aluminum and the hubs are PVC. This is just a model. In a full-scale structure I'd use steel. (If any of you have expertise in using light-weight steel in home construction I'd love to have a conversation!) Any thoughts much appreciated.

Fred

-

@fbartels said:

...I built the prototype in the images (previous post) in the last few months. The metal joist hangers are aluminum and the hubs are PVC. This is just a model. In a full-scale structure I'd use steel. (If any of you have expertise in using light-weight steel in home construction I'd love to have a conversation!) Any thoughts much appreciated.

Hi Fred,

I love the smooth curved roof structures that you’re designing in SU. And I’ve seen the experiments that you shared with us, for instance with bamboo material.

Later you used PVC tubes in each joint, and aluminium as a follow-up material.

What keeps me puzzled (after seeing the details so far) is how you deal with bending stress in the overall structure. Compressive stress (at the top side of the roof shell) and tensile stress (at the bottom side) needs to be dealt with in each joint. And near columns (near / in facades) there’s also shear stress to deal with.

PVC will certainly not do in larger structures. Aluminium tubes to a certain extent.

Large structures (as for houses) need a carefully designed joint structure that can deal with the maximum compressive/tensile stress (due to roof load + snow/wind etc.) in the middle and total shear stress at the roof circumference. And with any combination of stress for joints in between.

I read that you are still working on the steel version. Although I have no direct expertise on such details I just wanted to share my thoughts about the subject.

Nice project! -

Wo3Dan,

Thanks for sharing your concerns about compression and tension stresses at the joints. I have them too. It's why I'm proceeding slowly and with small projects first. I think steel hubs and joist hangers will go a long way toward addressing this issue. I'd love to know the math to calculate the stresses.

This small dome http://dws.editme.com/files/JulyAugust2009/IMG_5882.jpg & http://dws.editme.com/files/JulyAugust2009/roof%20beams.jpg is going strong even with poorly designed posts and PVC hubs with joists attached via end grain screws. It has had some major snow accumulation and has not shown any deformation.

Have you seen some of the bigger grid shell structures? http://www.metropolismag.com/story/20061011/back-on-the-grid

I suspect the stresses in them are similar to those in my framing system.Cheers,

Fred

-

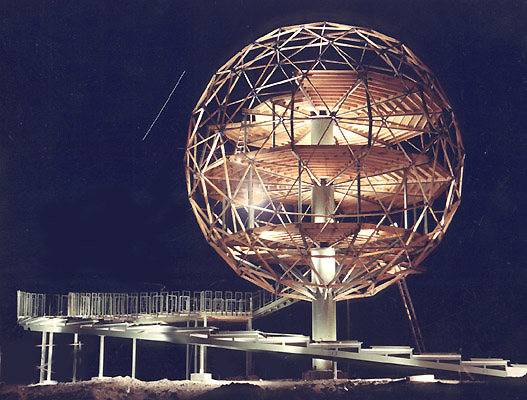

Regarding a bigger shell structure. This system was designed by Billy Woods of Dynadomes.

I filmed the building of this structure in 1970.

And it still stands.

I think it also appeared in Stewart Brand's book "How Buildings Learn."

I sent you an SKP of the connector system.

Advertisement