[Plugin] Slicer5

-

Hi TIG

Brilliant plugin. My only problem is I am not getting references shown in the resultant flattened slices? Have installed txt_.ttf into (Win7) Windows > Font folder. Is this where the plugin will look for reference fonts?

-

@argo said:

Hi TIG

Brilliant plugin. My only problem is I am not getting references shown in the resultant flattened slices? Have installed txt_.ttf into (Win7) Windows > Font folder. Is this where the plugin will look for reference fonts?

Duh! moment on my part

I was not zooming in enough to see the text

I was not zooming in enough to see the text

-

Perhaps you need to set the text-height to be larger in the tool's dialog

Or invest in some new spectacles

-

Hello

I've got a technical question I'd like help with if possible.

I've installed v5 and have used it to slice models using the dual axis, but I'm having difficulty using the R and A axis.

When selecting A axis, SU seems to run through the steps, showed on the status bar, but once finished, the original model disappears, along with the RGB/XYZ axis, and when I click zoom extents, nothing shows up. Clicking on undo and then re-zooming shows the original model before the slicer has run.

Selecting R axis simply doesn't do anything. The dialogue box closes and SU reverts back to the select tool with no alteration to the model.

In both these cases I have been trying to slice a simple cylinder 200x200, with no additional features used on it. It is located with the centre on the Z axis, and to the best of my knowledge is a viable component, as it works fine when slicing in one and two axis modes.

Thanks for your assistance

-

It might be an issue with the size of the object/slices.

Sketchup itself fails to make geometry with very tiny dimensions...

Try scaling the model up by say x100 [tapemeasure tool two points known to be say 10mm apart and type in 1000mm] - answer 'Yes' to rescale everything temporarily] and then make the slices [making sure to multiply the values in its dialog to match the new size [x100]].

You must remember to scale down the model on completion using the reverse steps - tapemeasure something that ought to be 10mm but is now 1000mm and type 10mm... -

Hi tig.

I try to install slicer, but didnt work fine. I'm new at this, im trying to install but couldnt place the first zip, i don't know where exacly it goes.

Thanks.

-

I've installed the ruby window, but it doesnt show anything inside the box, sure I did something wrong, but dont know what exacly.

Could you please give me any recommendation. I really apreciate itThanks

-

I recommend you get some 'help'...

Please look at this post about the 'SketchUcation Plugin Store'

http://sketchucation.com/forums/viewtopic.php?p=467479#p467479

You need to install one tool from an RBZ archive that you need to download... BUT that is clearly explained in the help page [linked from the main-page at the start of the text].

If you can't succeed in doing that simplest of steps then you will come back here...Once that 'SketchUcation Plugin Store' tool is successfully installed, then you can browse through, read about, and then install almost all of the Plugins that are featured in the pages on our forums [including of course 'Slicer5'] - you can use the dialog's Auto-Install feature which removes all of the headaches of installing things manually ...

However, note that there are also some other tutorial/help posts on the forums, which cover installing scripts manually - these might be useful if you find a script from another site that needs a manual installation... -

Hi TIG, thanks again for this great tool.

I'm trying to use slotter after maipulating the slices (unslotted but flattened)

When I select a the entire model, the whole set of flattened x slices, or a particular slice component(group?), I get an error: Selection is not a Slices NNNN group.

How should I select the model or part of the model to get it to perform the slot function? -

Select the assembled set of slices.

It should then be seen as the

If you've exploded it you a screwed, you can edit in situ...

-

Tig, could you add 'use current UCS' (incl. start slicer from current 0,0,0)feature? It'd simplify the things a lot.

-

Why not place your slicer solid at 0,0,0; rotated as desired.

I would never slice an object with a wider model, it's not safe !

Work in a specific model containing just that object.

Select copy, new SKP paste ? -

Donno, twisting object sounds sooo counter-productive and unnatural

-

I'm trying to use the slicer tool and keep getting an error message that says "The selected object is NOT a manifold solid". I am trying to slice a part that was made from two lofts that were stitched together. I'm sure that is the problem. How can a make the part a solid?

-

There are several separate threads on making things solid...

You can search for those and read up on the issues...Here a précis...

A 'manifold' solid is a group [or component] that contains only geometry [guidelines/points are also permitted as they never interact with other objects, but best avoided].

Geometry is defined as faces and their edges.

So that means...

NO nested groups or component-instances or images [if so explode then into the 'container' group].

NO other objects like text, dims etc.

Every edge must have two faces associated with it.

No fewer and no more.

So that means...

NO faceless ['lone'] edges.

NO edges with one face - e.g. as flaps, shelves, hole-perimeters etc

NO edge with three or more faces - e.g. internal partition faces, where some edges will have three or more faces, and no otherwise-solid-blocks meeting along a shared edge that then has four faces etc.

NO coplanar faces exactly duplicated and 'overlaid' - these are difficult to 'make' manually because such faces usually 'merge', but sometimes faces like can result from complex operations and they can be hard to find without helper tools.***

Faces should also be consistently 'oriented' - with their front-material outwards [although a completely inside-out object will still be consider as a solid if there are no other issues with its geometry].When checking your object ensure that all hidden entities as visible [View > Hidden Geometry ON], and that all layers are switched ON, in case some things that are causing issues would otherwise not be seen.

Sometimes you can have very short bits of lone-edges or tiny holes which stop your object being solid.

These can be hard to find.***Thomthom has made the 'Solid Inspector' tool, which will examine a selected non-solid and highlight problem areas.

These will then need fixing manually, or my 'SolidSolver' tool can try to repair it - although if the object is badly formed with several issues it can fail.

To assist you in a manual repair use a Style that has clear front/back default materials and view in Monochrome mode and 'reverse' selected faces that are 'backwards'.

The Style should also have end-points ON, and distinctly different edge and profile edge thicknesses to help you find flaps and holes.

X-ray mode toggled on/off helps you see whats inside the object - like internal-partitions and overlaid faces

To work inside a form use a section-plane cut and delete unwanted partitions and flaps internally.

In tricky internal areas temporarily hiding or deleting a face so you can gain access to delete things is also an option - but in that case remember to unhide or reform the temporarily removed face [as that itself will case non-solidness].

The 'Entity Info' dialog shows if a selected object is a 'solid' in its 'header' text... If it doesn't say it's a 'solid' then it is not a 'solid' ! -

Yes, the Solid Inspector did the trick. Thank you!

-

Okay.. i've been waiting with writing here for a looong time, but now i find myself in situation where this plugin would be very helpful indeed.

And.. surely enough i have a problem with it.

My problem is almost like everyone elses, but i am providing the file so one could check on it.

http://www.mediafire.com/download/38k93ic1qhwmne8/droplet.skp

So.. what i have done there is make a wave pattern i wanted to slice, and by now, it's not even important what settings i use, as the problem seems to presist thoughout the tries. But for accuracy sake here are examplary ones:

Axis: Y

Spacing: 3

Thickness: 1

Insets: 0

References: No (though i have the font installed and with or without references, problem's just the same)

Flatten: NoThe first group gives me just 1/6 of one slice. Yup.. one sixth, as seen here:

(The dimensions are outside of the group)

So in order to ckeck what is failing i tried to scale up and down, with no success, then, as seen in file i took the model, cut out 1/4 of it, scale up, (reducing geometry this way)and try again.

This i've done few times reducing the geometry to nearly 6 faces... and still getting this error.

Now, what i mean by "nearly"... on the two last groups you can see the hidden lines that when erased, delete the top face. This shouldn't happen, as it began as a flat surface, and cutting it down should not change this. And so after using align tool and making it flat again, slices are cut correctly.Now i wonder.. where this additional lines come from? Because if they exist in the model and mess up slices and are not visible and therefore not fixable, that means.. i am doing something wrong.. or not.

Don't want to write a book about this so i'll just write, that i used cleanup plugin, solid inspector, purged model completely, disabled and then deleted plugins that could cause problems (the ones i know of) and nothing really helps.

What is interesting, though, and worth mentioning,the very same geometry produces considerably less errors (even down to zero) when being sliced at different angle.

Try:Axis: A

Spacing: 1

Thickness: 0,3For three interesting effects see A axis with angle of 30, 34 and 37 degrees. They behave oddly differently.

Now.. is it problem with me doing something wrong, my model, slicer plugin, other plugins or sketchup? -

It's possible to make a surface too complex for SketchUp to Intersect a face with successfully.

Your surface has thousands of triangulated facets and cutting a face through many of them will occur near a vertex - the resultant piece if edge will have a start and end so close that SketchUp's Intersection tool's tolerance will fail to make the edge as it assume two points that are so close are in fact coincident and therefore a zero length line is not made. This leaves a gap in the potential loop for a face which would then form the basis something to PushPull to the required thickness...This occurs in many SketchUp tools like Intersect and FollowMe.

Slicer uses the API intersect_with method so it fails too.To see this without Slicer.

Make a large rectangular grouped face and position it cutting through the form.

Edit the group and select the face.

Switch View > Component Edit > Hide Rest of Model ON so you can see the results.

Use the context-menu tool 'Intersect with Model'...

Sometimes the intersection will form a full loop because all new edges vertices are regarded as non-coincident and could be PushPulled... BUT if you Undo and Move the group slightly, so that it cuts near to a triangular facet's apex and retry the Intersecting as above it'll probably leave tiny gaps in the loop so then no PushPull is possible.What you have just done is what Slicer does, but automated so the cutting face steps along and intersects/pushpulls etc...

I am sorry but your form is one of those that SketchUp can't cope with... You can try simplifying the mesh, but I suspect that at some locations you'll always fall foul of tiny edges missing...

Scaling up >=x100 will make the vertex coincidence less likely but no always

-

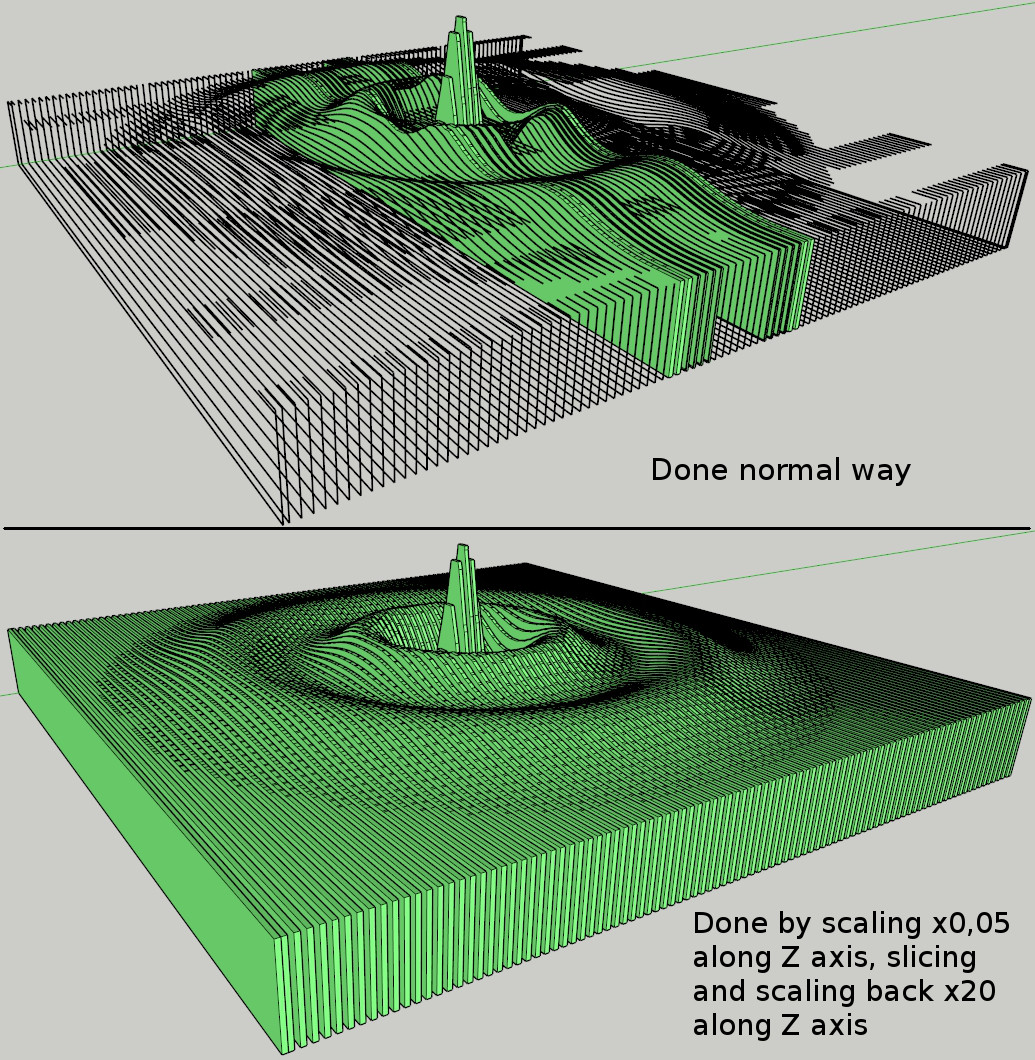

And this would be perfect answer for my question if not the fact, that... see here.. if you take that model and scale up, there are still some slices that aren't made.. but then again, if you scale it down to like 5% of its heigth (other two axes left unscaled, because scaling whole model down and slicing causes bugsplat) what it does is decreasing size of the triangles or leaving them unchanged, depending on if they are paralell to the floor or not, but then all slices are ok, and after slicing when scaled up again, it's all fine.. (just noticed it now).

Now, if triangles can be smaller and still be cut properly, then model being to small isn't really an issue. Or am i missing something?(this ofcourse is a workaround for my problem, but it's still something that should be resolvable, since "scale and triangle size" explanation doesn't seem applicable in this case. At least not directly. So there have to be another thing that causes problem..)

And.. it this worked for me, this could be resolution to all slicing problems.. just scale down the model along the axis you will slice model, slice it and scale back up. Then, if necessary, repeat with other axis.

And one more thing. I have just created torus out of over 4000 triangles, then sliced it to 200 slices and... every single one came out correct.

My model has below 2000 triangles and in the same scale, when sliced just now produced.... three slices correctly...And the last thing..

After another 10 minutes slicing stuff.. i conclude again that SU is a tool far, far away from being perfect. So many flaws and errors..

Every scale and every shape is treated differently. And from my point of view, this indeed isn't slicer problem, but SU itself, as those kind of problems i encountered in many places thoughout my work with SU.. soo.. let's just conclude, that in order to do things properly, one have to try, and try again.. it has to work one way or the other.

Thanks for your help.And to show that it can be done, a picture

-

Glad you managed to get a result

Advertisement