[Plugin] Slicer5

-

@daniel s said:

You are right It will be limited to 'RZ'.

I started using and don´t read the instructions... the radially is only from the Origin [0,0,0].

To make this for example I had to rotate the object to get the desired result.

Thank you,

Daniel S

As you 'discovered' by using... the rotation for set of Radial Slices is always around the Z axis, so you might need to relocate/rotate the Sliced Object accordingly - it is in the Notes as you also subsequently discovered ! -

@miki71ita said:

:oops: Hi people... I have a problem with Slicer5 v5.5. Saving slices as images in .PNG format, I always have this kind of Bug with all my .STL models:

You are a few versions behind...

You don't give us much of a clue about what the Sliced Object is like, the Axes used, Slice Thickness/Spacing etc etc.

The issue isn't with the Exporter - it's with the Slice making itself.

My first thoughts are that the Object you are trying to Slice is too small.

Sketchup/OpenGL have issues with very very small [or gigantic] sizes.

Sketchup can't make a face <~1mm or 0.001sq".

That's why Followme around very tight radii etc can fail on small pipes etc.

The recommendation is to Scale up x10 [or x100] and do the Slicing [or any other similar operation], then Scale down x0.1.

Small faces can exist, it's just making them initially that is awkward.

The Slicer tool uses 'intersect_with' type operations to make the faces, if some edges aren't forming it's a good indication that they might be too small.

Because you are using the PNG format the actual size of the Slices is also not critical - you must specify the 'real' size to software using those PNGs; each PNG image is sized relatively to the screen [others] but the used-size needs specifying in your STL app.

Alternatively... IF the error is just with one piece one having and incomplete edge then why not try manually editing the slice, adding in the missing edge detail manually so it is healed, then use the separate Export tool on the Flattened set...

I'd be interested in learning what the issue was/is... -

Here's v5.8 http://forums.sketchucation.com/viewtopic.php?p=374969#p374969

Glitches with the Slot-2 width and Slice-2 Ref-tag's location fixed.

New 'AZ' version added - now you can Slice at an Angle around the Z-axis AND in the Z-direction and intersect them with slots etc. See the updated Usage Notes... -

Here are some example images - more welcome...

-

Here are some 'Head' slices...

-

And a Contour model - useful for making a Kappa Board 3d real model.

Here Slice Spacing and Thickness = 1m...

-

Tig,

On the contour sample you showed is there a way for an outline of the smaller piece to be shown on the larger piece so when making the real model it will be easy to line up everything properly?

Thanks,

Cubcrafter

-

@unknownuser said:

Tig,

On the contour sample you showed is there a way for an outline of the smaller piece to be shown on the larger piece so when making the real model it will be easy to line up everything properly?

Thanks,

Cubcrafter

Funny you should mention that... I thought of it when I looked at the image too...

I'm thinking about it... Perhaps an extra tool to 'emboss' the part below onto the set? Z002 gets Z001, Z003 gets Z002 and so on... It's NOT as easy as it sounds ! -

@tig said:

And a Contour model - useful for making a Kappa Board 3d real model.

Here Slice Spacing and Thickness = 1m...This reminded me of this: http://www.challengermap.org/history.htm

There used to be school trips to see this map in the good ol' days. Lends meaning to the expression "Patience of a wooden god." It was neat to ride the gantry over top of the map - photos don't do justice to the size. Imagine now - Tig's slicer and cnc router. -

Yes, labeling and aligning would be useful tools.

Fantastic work Tig! -

Here's v5.9 http://forums.sketchucation.com/viewtopic.php?p=374969#p374969

Please [re]read the Usage Notes - it has several changes and additions...

The Exporter is now a separate tool, there are now no prompts after Slicing, it must be run separately later on.

If Axis==X/Y/Z/A and Thickness==Spacing then new option to add 'Outline' [OLIN group] from the adjacent Slice, it helps in assembling the real 3d pieces.

If Exported DXF includes an OLIN then those are put onto a layer 'OLIN' which can be used for 'etching' an outline [like Text].

If a Slice has manually added circular holes <12mm diam then these are also put on their own DXF layer, 'CIRC'.

Exported PNGs now made 2x viewport size for sharpness.

Exported PNGs from a Flattened set containing a FLAT2 are now consistently sized, based on the maximums of BOTH FLAT sets and guide-points are shown at TR/BL/CT. Shadows are now automatically set 'off' when making the PNGs.

An 'RZ' option has been added, to make Radial Slices intersecting, and potentially slotted, with 'Z' Slices.

Glitches with Spacing/Spaces dialogs resolved.

-

TIG, thank you again!

-

Thanks TIG!

-

Here's v5.10 http://forums.sketchucation.com/viewtopic.php?p=374969#p374969

Please re-read the Usage Notes... it has 2 major new tools added.

'Slicer5 Slotter': after manual relocation or resizing/shaping of [non-Slotted] Slices in dual-axis 3d SLICES set, it does Slotting of the sets' Slices [reflected in the FLAT sets]; useful if you want to have some narrower or angled 'slats' etc. This offers considerable flexibility in allowing adjustments of non-slotted forms and the individual slices, which can then all be Slotted together later - see Usage Notes...

'Slicer5 Audit': checks 3d SLICES set against the FLAT set; also Text-tags [if any] are updated to reflect the Slice's current name [useful if you have manually copied a Slice (say '1234-X001') and then used 'Make_Unique' on it to make a new Component (say '1234-X001#1') and edited its form etc, because the Text-tag will not now reflect that Slice's new name]; all

changes reported at end in an Audit_Report txt file.

The Audit also runs before any Export and stops it if any significant errors are found; to allow you to consider the implications - see Usage Notes...There are also some minor adjusts to dialogs' text, layout glitches etc.

-

The first, thanks for the plugin, but on Mac when you select "Add References? -->Yes" the plugin doesn't work, if you select ---> No the plugin works fine.

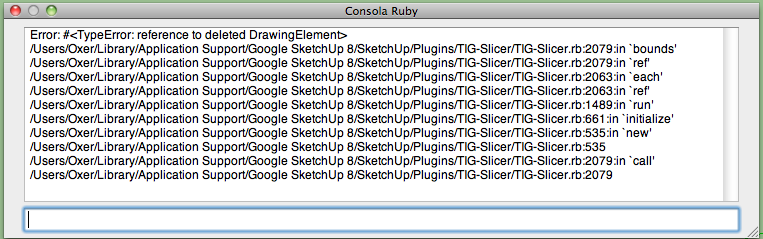

This is the Console error message:

I don't know if there is a conflict with other plugin, i'm going to uninstall other plugins, later i inform you.

-

The failure is because the group of text doesn't seem to exist

It creation might be failing because you don't have a ttf Font called 'Txt' on your MAC ?

On a PC if the specified Font is missing then the last used 3d-Font is substituted - e.g. 'Arial'.

To see if it's this I've provided a 'Txt' .ttf Font in this zip file... txt_____.zip...extract it and put it into your system Fonts folder... and see if that then works...

If it doesn't... can you try this manual 'equivalent' for me.

Open a new empty SKP.

Copy/Paste + <enter> into the Ruby Console, each of these lines in turn...

gp=Sketchup.active_model.active_entities.add_group() txt="X001" gp.name=txt tgp=gp.entities.add_group() tgp.name="TEXT" tht=50.mm tgp.entities.add_3d_text(txt,TextAlignLeft,'Txt',false,false,tht,0,0,false,0) tm=tgp.bounds.min

You should end up with a group called 'X001', which contains a group called 'TEXT', that in turn contains the 'flat' 3dText 50mm high, saying 'X001', and return the minimum bounds corner {[0,0,0]?} ???

Report what happens at each step...

If it fails at all please try this in for the last but one line of code...

tgp.entities.add_3d_text(txt,TextAlignLeft,'Arial',false,false,tht,0,0,false,0)

As you should have always 'Arial.ttf' ?

-

Ok TIG, i'm going to probe these solutions, later i'll inform you of the results.

-

Fantastic, the plugin works now with References. The problem was that i haven't installed the Font "txt.tff"

Thanks TIG for your quick reply.

-

I have translated the last version of the plugin to spanish language, if you want i can upload the translation here.

-

@oxer said:

:berserk: Fantastic, the plugin works now with References. The problem was that i haven't installed the Font "txt.tff"

Thanks TIG for your quick reply.

OK - I'll add that font to the main download in case any other MAC users have the issue...

As far as the translation goes... I've no plans to translate [deBabelize] it... not yet... BUT if you want to post your translation strings, then I can use them when I do [for v5.11+ ?]

Advertisement