Check out this extremely talented modeler

-

....I think there is no objection?

http://forums.sketchucation.com/viewtopic.php?f=81&t=33509&p=365243#p365243 -

I really appreciate the tips, I think I'll be able to make wires that no longer look like a snake run over by an 18-wheeler. That's one of the fun things about SU, you can always learn better ways of doing things.

BTW, your Highboy is looking great! Can't wait to download it (and then delete it out of frustration and jealousy )

)@urgen said:

....I think there is no objection?

http://forums.sketchucation.com/viewtopic.php?f=81&t=33509&p=365243#p365243My only objection is that you beat me to it! Gonna add a few more photos to the thread tho.

-

I do wires with Pipe-along-path RUBY. Much like JMJ, I start with straight line segments to rough in the route, then apply 6 segment arcs to round the bends. That is the time consuming part, to get them right. When it looks right I PAP using zero inside diam and usually 8 or 12 sides, depending on the detail I want. Wire rope is always 6 sides. Then I smooth/soften all inside segment joins. If I want a more realist look I break the long runs in random places with full circles, and tweak them out of alignment to give the wire a bit of a wavy look.

When I get a chance in the next week or so, I will post some images of my Silver Dart project in the Most Impressive thread. It is far from complete, but the engine and landing gear are complete. It's fairly detailed, but not nearly as much as JMJ's engine. I can just imagine the hours it took him to do the timing chain to that level of detail. It took me days to get my chain drive to look only almost good.

-

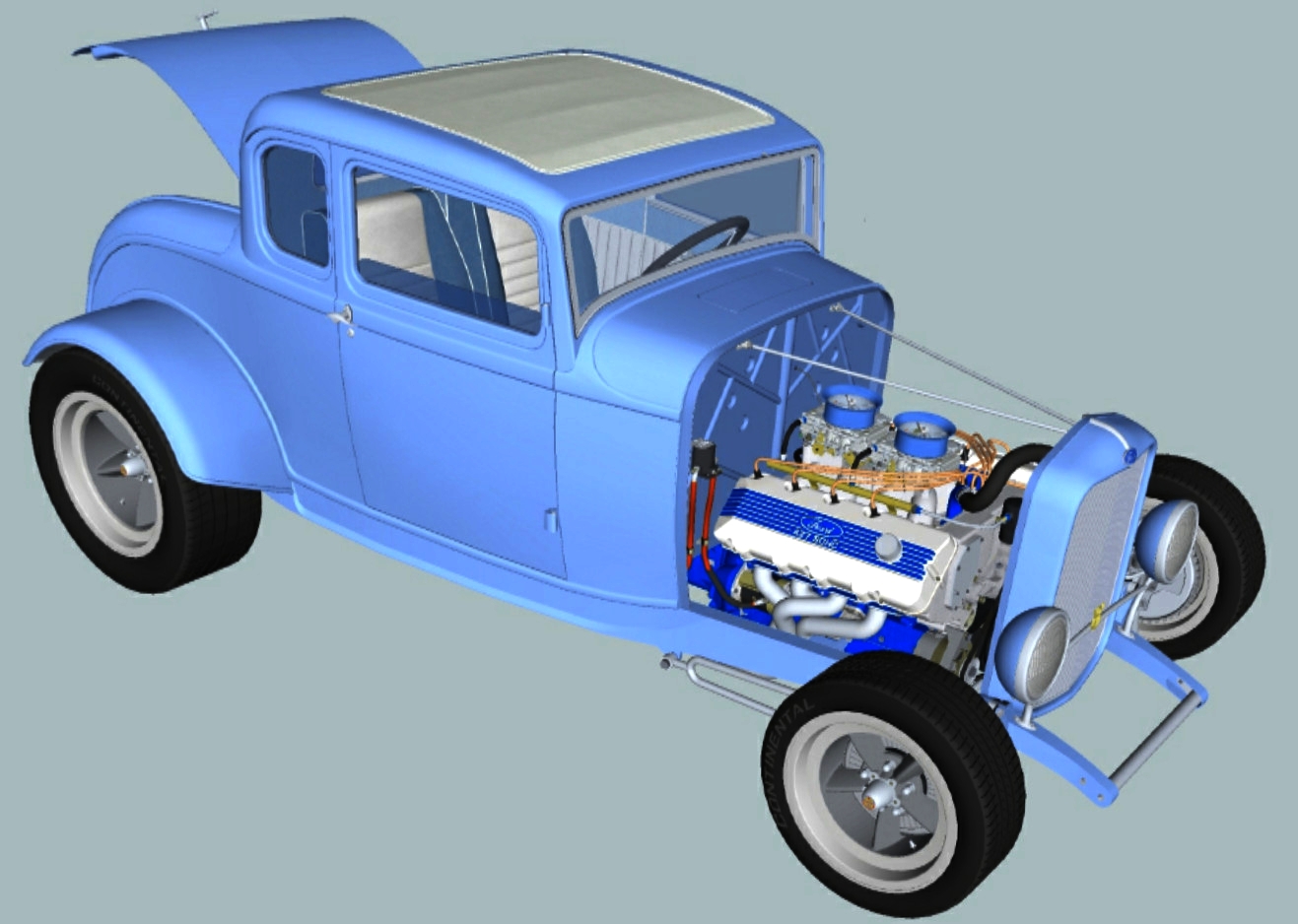

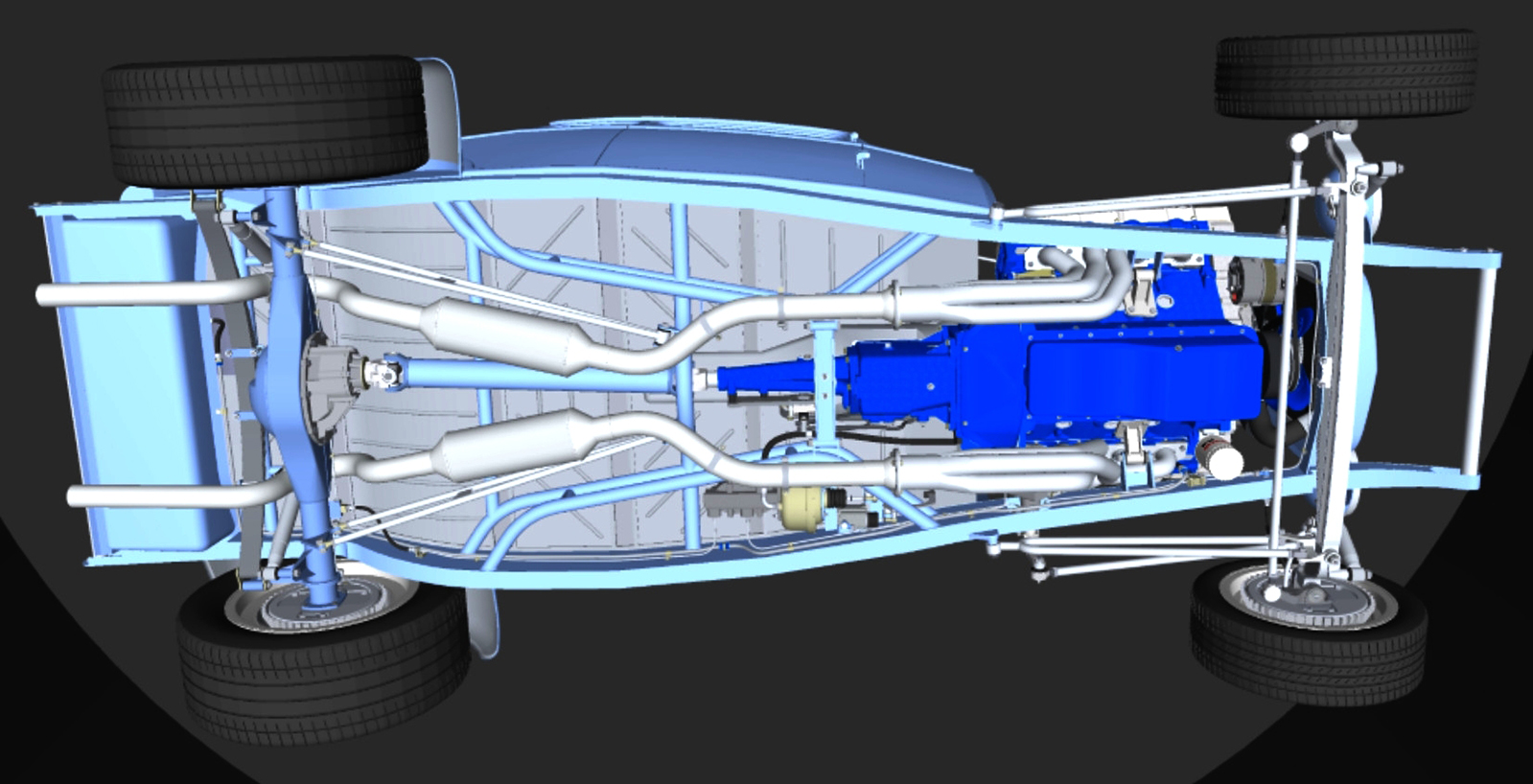

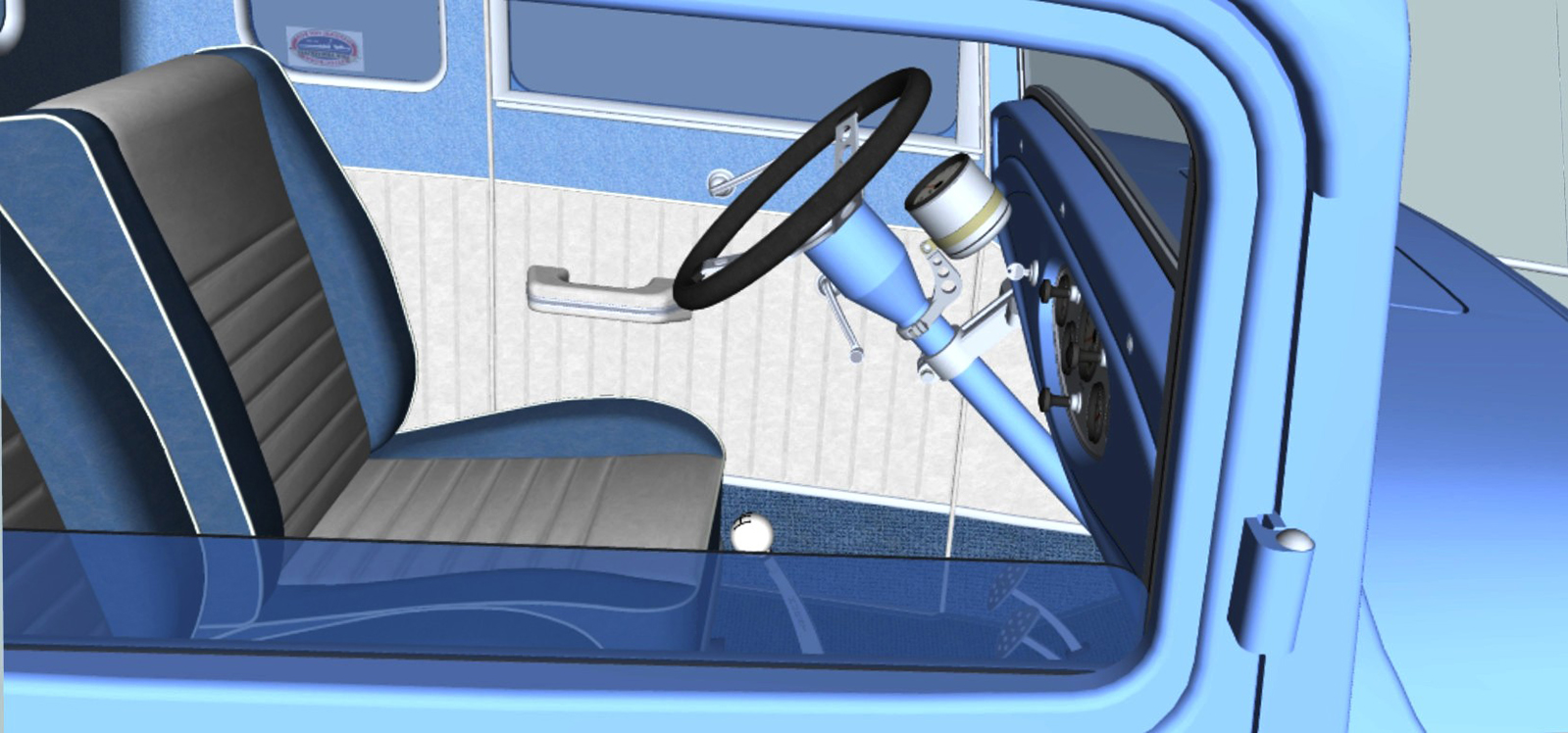

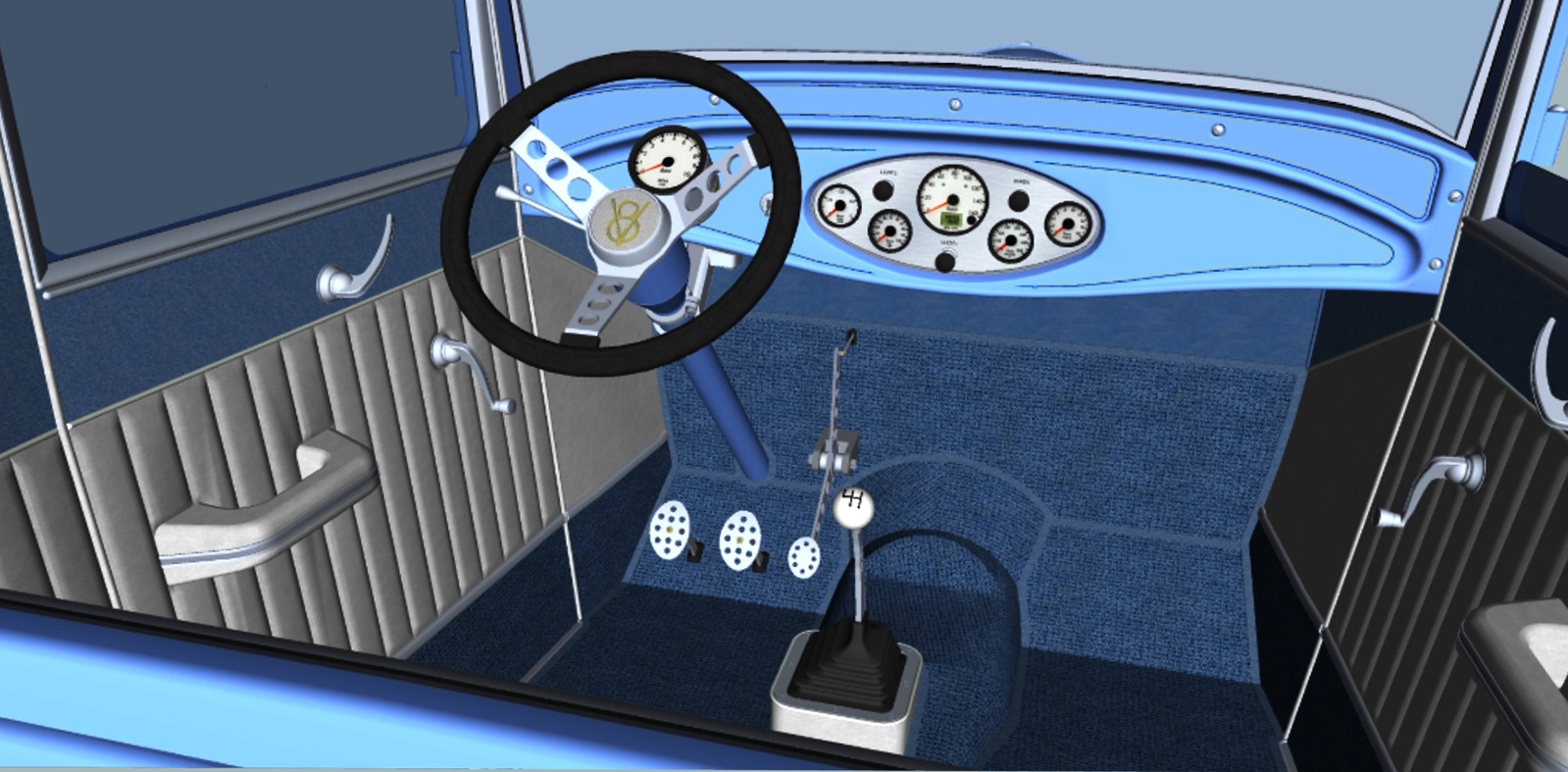

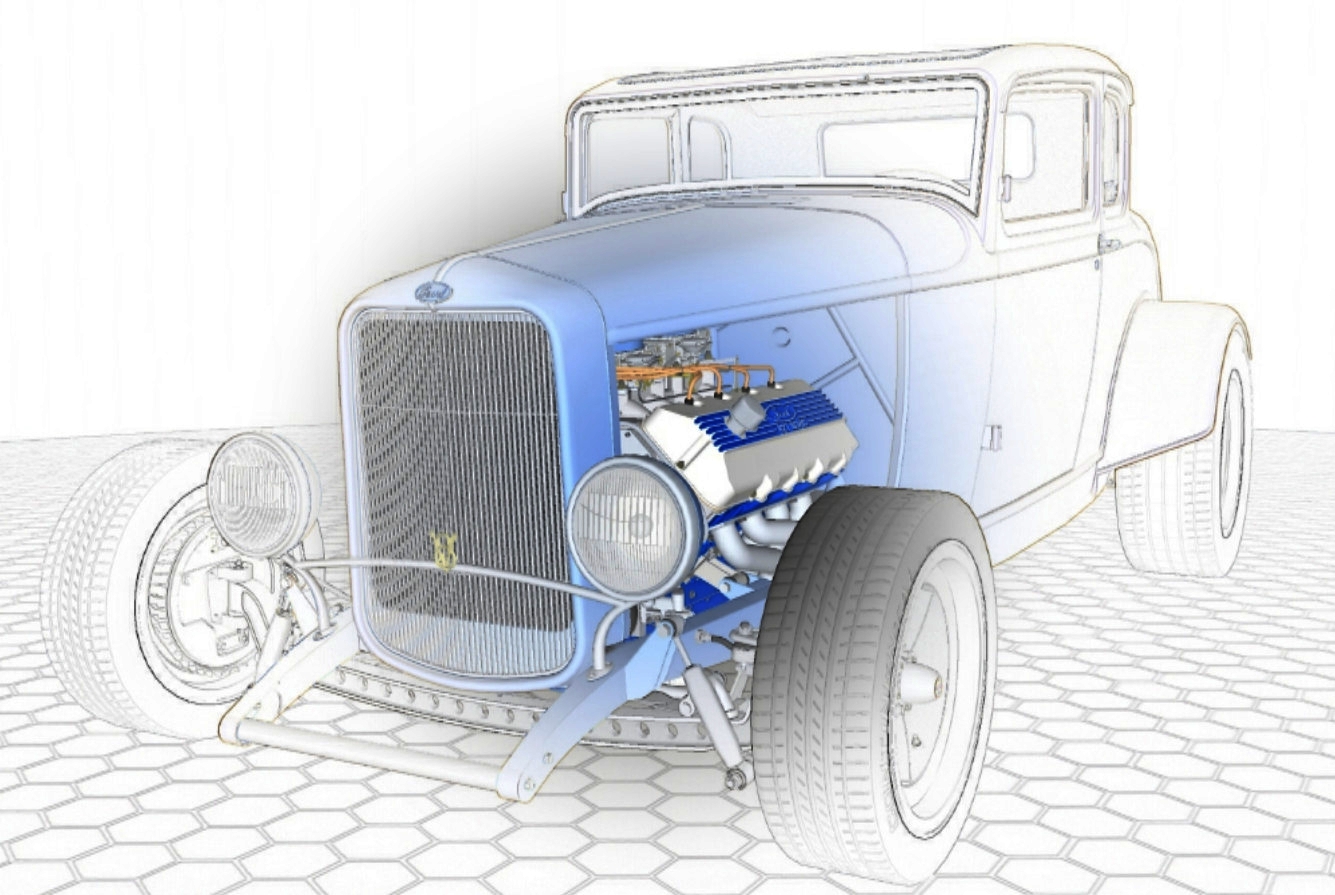

While JMJ hasn't finished his fantastic '32 Highboy and thus hasn't uploaded it to the Warehouse yet, he's getting close and meanwhile he has posted some photos of it's progress on the warehouse. Here are some of them. (Keep in mind, these are copies of the photos, so they have lost some detail and do not do his work justice)

Part of his description -- "Here is the current state of my 32 highboy. Will be adding the following; Windshield wiper arm and blade, clamps on lower radiator hose, front turn signal lamps, seatbelts, interior dome light, rear view mirror, voltage regulator and additional engine wiring."

He describes the photo below as "Created this pencil render with shaded highlight in PhotoScape.

-

The Highboy model is wonderful. It's nice to see JMJ has joined the forum!

-

....JMJOhio,Thanks once again!

...some edit model for render...fast Hypershot+photosnop....

....

-

Wow, that looks like it's sitting on a shelf at Batteries-R-Us! Looks great!

dang, I wish I could render

-

Me, too. But then, I wish I could model faster and better than I do.

-

@urgen said:

....JMJOhio,Thanks once again!

...some edit model for render...fast Hypershot+photosnop....

....

[attachment=0:1m09mo8a]<!-- ia0 -->accu.jpg<!-- ia0 -->[/attachment:1m09mo8a]Great render urgen.

-

I clicked on the "photo" and my Laptop said "Charging!"

-

-

@urgen said:

....JMJOhio,Thanks once again!

...some edit model for render...fast Hypershot+photosnop....

....

[attachment=0:3cgd8z0y]<!-- ia0 -->accu.jpg<!-- ia0 -->[/attachment:3cgd8z0y]Thank you urgen. Great rendering. Can you offer any suggestions/recommendations relative to the model creation process that would reduce the render efforts, (preparation, render specific set-up and post editing) and still offer the best final image. A very broad question and looking for simple answers. Structure, organization, applied materials, imported images, etc...

-

@jmjohio said:

... Can you offer any suggestions/recommendations relative to the model creation process that would reduce the render efforts, (preparation, render specific set-up and post editing) and still offer the best final image. A very broad question and looking for simple answers. Structure, organization, applied materials, imported images, etc...

…JMJOhio, very general indeed…

....I do not use rendering in my full-time job and, therefore, cannot consult you professionally.. . Just for fun, I use HYPERSHOT or KEYSHOT… I think you should try to define a goal of the rendered image… Does a particular scenario take place? (Is it a coherent scene?) Or is it just an engineer type of render? May be it is a render for a magazine (like the battery project that I presented above)?

. Just for fun, I use HYPERSHOT or KEYSHOT… I think you should try to define a goal of the rendered image… Does a particular scenario take place? (Is it a coherent scene?) Or is it just an engineer type of render? May be it is a render for a magazine (like the battery project that I presented above)?

Depending upon the goal of your image, the render program should be adjusted accordingly. HYPERSHOT (KEYSHOT) gives one of the best quality results and is also one of the easiest programs to navigate, but its usage is limited to the rendered object....It was thought to be ultimately easy to use and at the same time produce good quality, just like the most basic camera «Say Cheese» and there you go, photos are ready!

It is suitable for the preparation of some detailed images with a general view, which can be used for advertisement projects or in the area of engineering.In case you are after interior design or scene (with a particular coherence), there are many options out there. VRAY, THEA (very popular in this forum) MAXWELL, and so on… There is always a choice, but I am not sure what level you’re after… I have to warn you, it is very time-consuming and demanding in terms of experience…@jmjohio said:

...The monkey can paint a masterpiece if given enough time and bananas.

............

.... the monkey has to spend hell lot of time... and eat far more bananas!

and eat far more bananas!

....Best of luck to you!

..In case you need help with HYPERSHOT (KEYSHOT) or PHOTOSHOP, do not hesitate to ask me and I will answer whenever I have free time.

-

Wow Jim. All I can say is wow. That is some really wonderful modeling.

-

I hate to point this out, but I think one of the head gaskets is about .0000000001" too thick. Ruined the whole model for me.

-

@hellnbak said:

I hate to point this out, but I think one of the head gaskets is about .0000000001" too thick. Ruined the whole model for me.

Rechecked the head gasket thickness and they are both within Fords' spec. tolerance range. You need to get your measuring devices re-calibrated and/or start using your good eye.

On a serious note, I stumbled upon a situation that causes me great concern. While surfing for project reference information, I found a Ford 427 v8 SOHC 3d model for sale on TurboSquid. My model being sold by someone else. I have had this model posted on my Google docs page as a shared file (my bad)for about 6 months. In the future, any sharing I do will be on an invitation only basis. I really enjoy seeing others utilize my models in their projects, but openly advertising and selling them in original state is not acceptable by me.

What have the rest of you experienced along this line and what are your opinions?

JMJ-Ohio

-

I am in agreement with you, in principle. However, you did provide the model in the warehouse supposedly open to all. I don't know all of the rules or disclaimers in regard to the warehouse.

My personal position on this is that, regardless of all else, I would respect the owner's intellectual property. And, as a matter of pride, I would try to originate my own material, then failing this, I would seek permission or license or purchase. -

I think this is despicable! I have been in contact with Turbosquid, and they said that they will verify the situation and their copyright agent will contact me tomorrow.

If I get nowhere with this, I will buy the model just so I can post a review of it and let people know that it is stolen and if they want the original they can get it free from the SU Warehouse. Hopefully that will prevent the buttwipe from making any more money off of your efforts, and maybe will alert others that he is a shady character not to be trusted.

I'm so sorry this happened

, I hope it doesn't sour you on posting your wonderful models.

, I hope it doesn't sour you on posting your wonderful models. -

Below is part of an email received from Turbosquid Customer Support

*Could you please provide us with information on what model you are referring to and who the rights truly belong to? We take copyright infringement very seriously and will bring this matter to the attention of both parties as soon as we are able to prove that it is indeed an infringement issue.

We will need to fully research the issue before we press charges against anyone. You will not get an answer right away as there are a lot of steps to this process.

Thank you again for the heads up.

Regards,

Kate McKesson | TurboSquid Member Services*

In response I provided her what information I had, along with the URL of JMJOhio's Warehouse engine folder, so I guess we just wait now and see what happens.

-

Was notified by Turbosquid "Copyright & Trademark Infringement investigator" that the stolen model has been removed from their site. I have also just started a new thread here http://forums.sketchucation.com/viewtopic.php?f=15&t=42399 to see what experiences other modelers might have had along these lines.

Advertisement