[Plugin] SolidSolver

-

@unknownuser said:

The .skp is 15.5MB so I don't think I should try to attach it

Sure you do!

First Zip it! (Right Click on the name file / Send to Compressed File ) you obtain a "zip file"

If it's less 2 Megas you can post it here elseyou can use something like WeTransfert.com (free) for share this file "ziped"

(trick : use also your email as "mail's Friend" so you will have the adress file

Put here the adress' file that you will receive!

& Voilà!

Anybody can read your SKP (for a week) even it's 1.99 GIGAS!

@unknownuser said:

over an hour now

That is that we call to be very patient!

@unknownuser said:

Problem was now almost all of the object was gone.

Curious! We are impatient to see that!

You must send at least an image!

(seems you don't follow the Golden rule: (Image(s) and / or File(s)) !@unknownuser said:

'Form has been intersected' mean?

Can be many thing but generally overlaping, intricated facets...

...but without image and or file we can't answer intelligent things!

-

If you try and model geometry as a solid it gives extensions like SolidSolver or SolidInspector² a chance.

That many entities seems a lot - what is it ?

When it says that it has intersected the form it means that some of your form's geometry penetrates another part of it.

Although it might even actually report as a solid in Entity Info it still cannot be 3d-printed, because of that issue.

It's an object that cannot exist in the real world.

SolidSolver intersects such a form with itself to try to avoid this issue - but of course then there are edges with more than two faces, internal partitions etc - all of which prevent it being a solid... so it must remove or edit those...

In doing so it might then remove expected faces etc and change the form...Try this approach...

Whether it's reported as a solid in Entity Info or not...

Edit the group.

Select all of the geometry [Ctrl+A] and context-menu > Intersect with Selection...

If it is not saying it's a solid in Entity Info, then it needs fixing...Get/Install thomthom's SolidInspector [v1 NOT v2].

Run it on the selected group and it will show several problem areas...

It shows, it does not fix.

SolidInspector² reports issues and then offers to fix those it can.

It might not spot all issues.

Often it cannot fix all issues.SolidSolver tries to fix all issues right off, but again it's not perfect and it might remove parts you'd like to keep !

Give these tools a break...

Edit the group and try and fix problems manually.Here are some basic rules for achieving a manifold solid...

A solid group [or component-instance] must contain only geometry - faces and edges.

So this means no nested groups and so on.

You can include guides, but they are again best avoided.Every edge must support exactly two faces - so that means...

no faceless edges [no matter how tiny],

no holes [no matter how tiny] where some edges have only one face,

no shelves or flaps where some edges have only one face,

no internal partition faces where some edges have three or more faces,

no otherwise seemingly solid forms like two cubes that share an edge, because that edge then has four faces.

no overlaid coincident faces sharing common edges - these can result in some 3d operations making some edges have that extra coincident face - one of those faces needs removing.All faces should be consistently oriented to face front=outwards, i.e. no back faces should be visible [appearance depends on the current Style, but usually it's front=off-white and back=blue-gray].

If it's a solid then the context-menu > Orient should fix such issues if one 'good' face is selected.As explained above a form can report as a solid even it it can't really exist - i.e. if it loops back on itself and penetrates a surface without having been intersected and the resultant problems fixed - like internal partition faces...

Also I'd recommend that everything is made on Layer0, and while trying to model a solid use the default material only [or at least view in Monochrome mode], and do not use any hidden or smoothed edges [which have no bearing on future 3d-printing anyway] - or at least use View > Hidden Geometry > On...

PS:

Tip: to see inside a form which has issues, use Xray mode or a temporary section-cut.

That way you can select unwanted edges or faces and use <delete> to remove them... -

@unknownuser said:

..but without image and or file we can't answer intelligent things!

except Tig who has made the plugin of course!

-

@pilou said:

... Put here the adress' file that you will receive!

... without image and or file we can't answer intelligent things!

Hope I did it right... Don't know if the comments show up, so here's a little explainer:

‘Reason for base - Dremel3D printer moves leg off build table... results in rats nest’

I am using this model to test the Dremel3D20... seems like a fairly complicated build, having to span the legs to build the body and do the tail... this is just a test

... and to learn SketchUp (and 3D design, in general)

... and to learn SketchUp (and 3D design, in general) -

This shows the issues...

Fix them.

The two 'flaps' in the ears are easily deleted.

The weirdness at the top of the tail is a bit more awkward...

I'll try to fix it...

-

Here's v7.0 http://sketchucation.com/pluginstore?pln=TIG_solidsolver It is signed for v2017 and fixes a glitch that a few PC users experienced if they have accents in their PC user-name.

-

Is it any major difference between this plugin and thomthom's Solid Inspector ( https://extensions.sketchup.com/en/content/solid-inspector%C2%B2 ) ?

Thanks.

-

Yes, of course... mine is better !

But seriously they do a similar process in different ways.

Sometimes thomthoms's thinks things are OK, when they are not, and mine can fix things over-zealously !

Try both - one of them might fix your problem...But if you model properly as you go along it reduces what needs to be fixed at the end, so try that first.

Also it's pretty easy to devise a form that is not able to made into a solid, no matter how convoluted your code gets...

So give us authors a chance... -

@tig said:

Sometimes thomthoms's thinks things are OK, when they are not, and mine can fix things over-zealously !

Thank you very much for your kind explanation! Of course I will try both and maybe even keep both, to use one where the other doesn't do it.

-

Hi Tig,

I get below issue when installing SolidSolver v7.0 in my SKU8 Free (ver.8.0.16846):@unknownuser said:

Error Loading File C:/Program Files (x86)/Google/Google SketchUp 8/Plugins/TIG-solidsolver/TIG-solidsolver_code.rb

undefined methodforce_encoding' for "langhandler.rb":StringError Loading File TIG-solidsolver.rb undefined methodforce_encoding' for "langhandler.rb":StringAny solution to fix it?

Thanks for your time. -

Sorry the latest update has string handling that needs Ruby better than v8's.

I'll publish and update which is less strict... -

Here's v8.0 http://sketchucation.com/pluginstore?pln=TIG_solidsolver it's now compatible with v8 again.

-

Great!! SolidSover v.08 works fine with SKU8.

Thanks for your quick reply. Cheers! -

Thank you for the many great plugins and extensions TIG!

You have made my SU life a lot easier. I am, although, having a bit of trouble with the current version of SolidSolver v8.0.

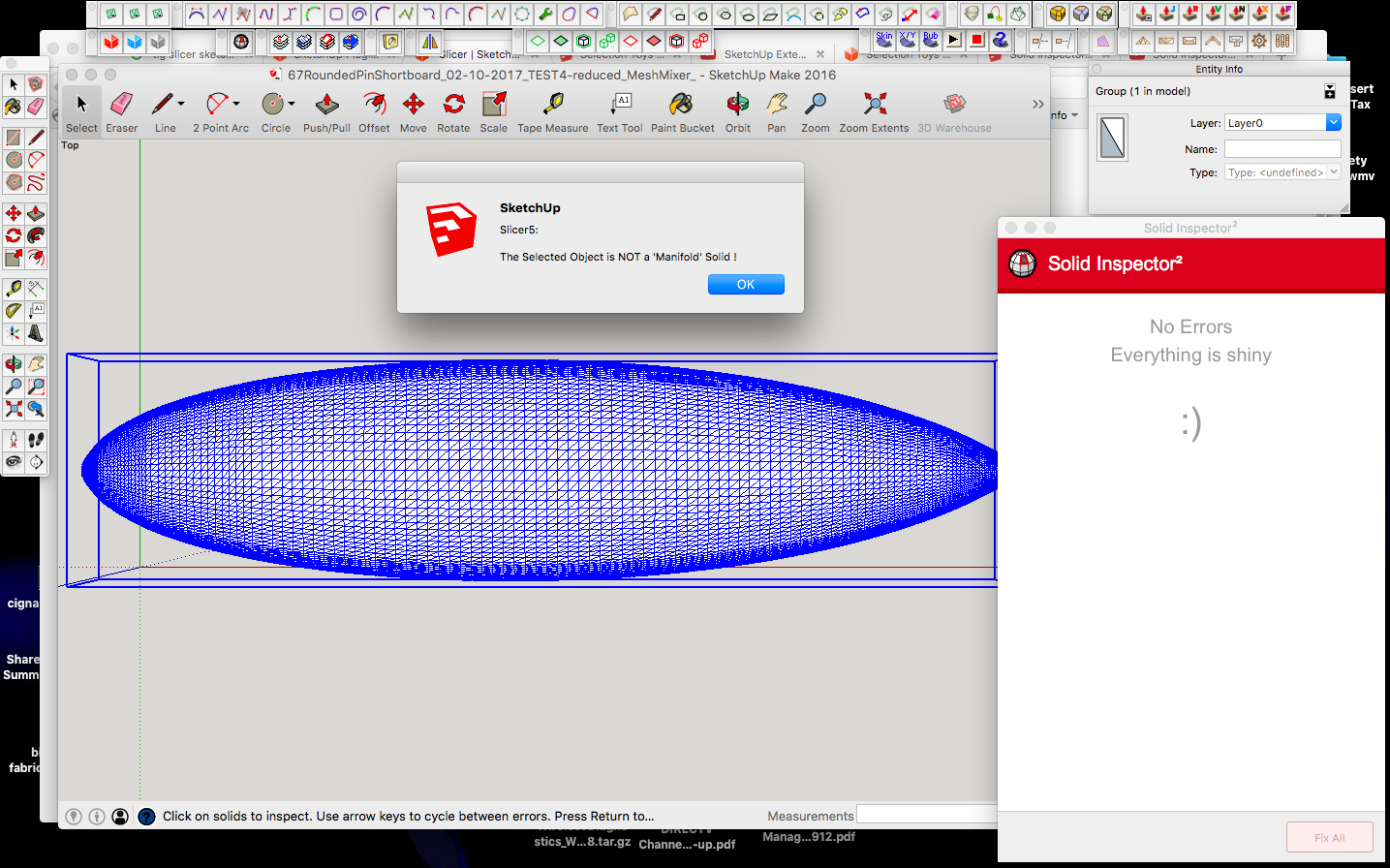

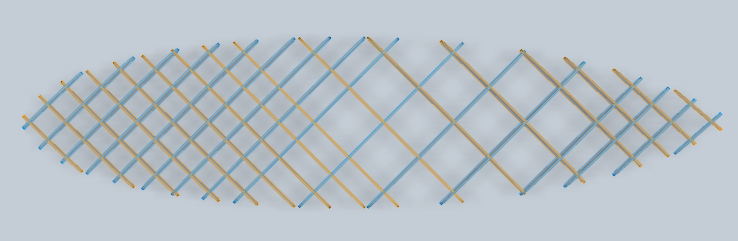

You have made my SU life a lot easier. I am, although, having a bit of trouble with the current version of SolidSolver v8.0.Background: I make wooden surfboards that have a wooden 'rib and spine' type structure as the core support and then skin the outside with wood as well. Using a surfboard shaping specific CAD app, I create the desired shape in 3d then export the mesh (.stl) file and then import into SU 16.1.1451. Would like to use your Slicer5 plugin but receive error 'not manifold solid'. Have used ThomThom's Solid Inspector2 and fixed all issues (using both Auto and manual correction). Still no go as the group is not showing as solid.

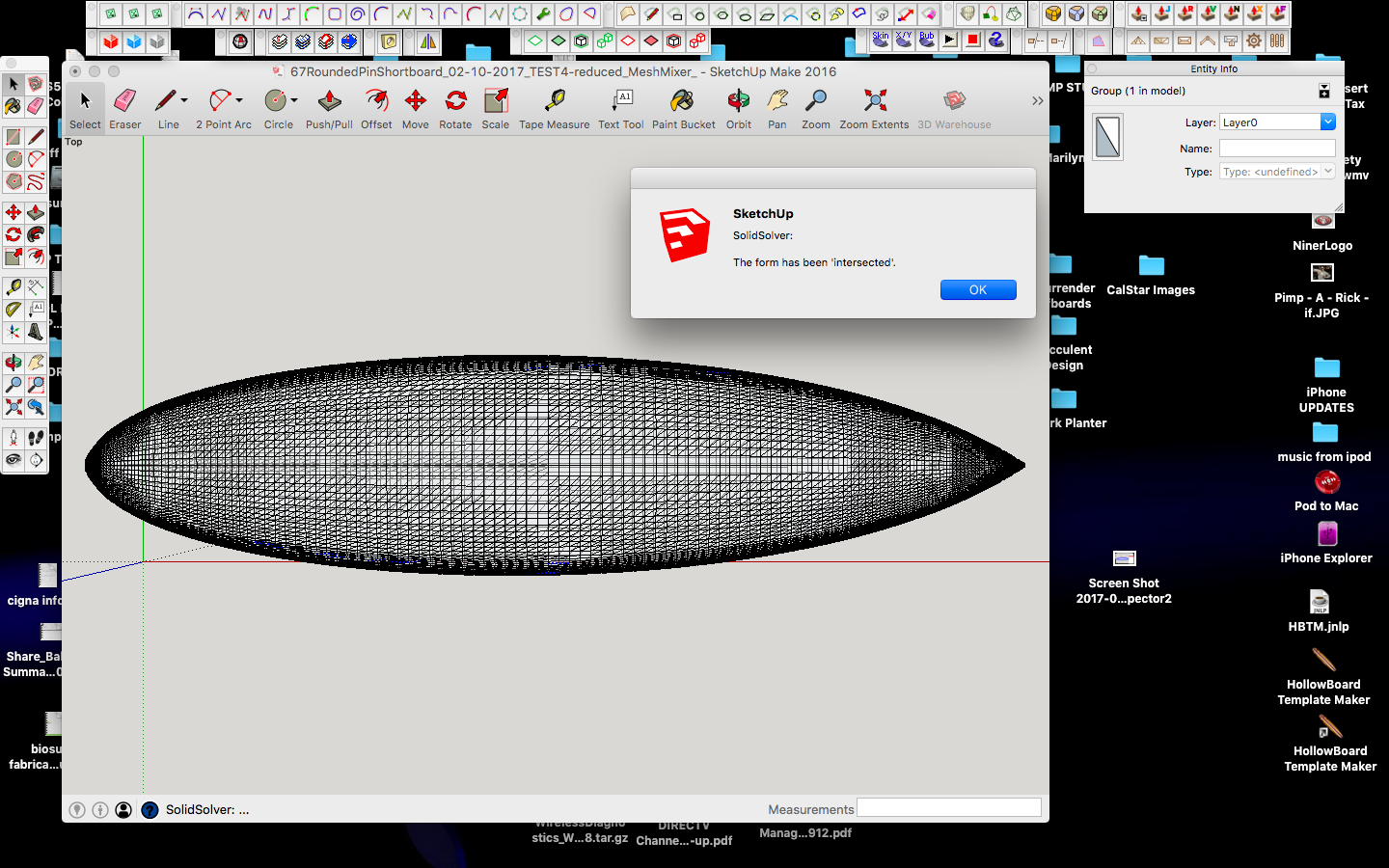

Tried SolidSolver and received report of 'Intersected'. Try to have your plugin fix issue, resulting in changing overall shape of my design substantially. Once that task completed, plugin provided another suggestion to fix (sorry, don't remember what dialog reported), selected yes and then SolidSolver hung for over 1 hour with SU reporting as 'Not Responding'.

I know I must be doing something incorrectly and could use some help. Ultimately trying to find best workflow to generate sliced model for CNClaser cutting skeleton structure.SketchUp 16.1.1451 file (zipped)

Thanks to any and all!

Rico

-

Thomthom's SolidInspector can sometimes report objects as OK even when SketchUp thinks they are not a manifold solid - Entity Info will say 'Solid' if SketchUp thinks it is - although it's still possible to make a self-intersecting 'solid' which cannot be sliced or 3d-printed in the real-world.

SolidSolver is less forgiving, but with 90,587 faces/edges to consider in your very [overly] detailed form I am unsurprised that it's taking forever to process...

It does not need to be so finely detailed for almost any use...Having done a little grepping I find that there are 35 edges which do not have exactly 2 faces.

Some have 0 faces - lone-edges

Some have 1 face - holes or flaps

Some have 3 or 4 faces - internal partitions

Mainly at the two pointed ends where there are many tiny facets.

They are all very short in length - SketchUp's built-in tolerance is 1/1000", and many are near that, and any 'intersections' etc will probably result in tiny unsustainable edges !

You could scale the group up by say 100 and see if that helps.

I've left SolidSolver running on it that way, and I'll report back...Even if it becomes a manifold solid chances are that Slicer5 will balk at it !

-

BugSplat after 20 mins !

Try making a simpler form...

-

@tig said:

...forgiving, but with 90,587 faces/edges to consider in your very [overly] detailed form I am unsurprised that it's taking forever to process...

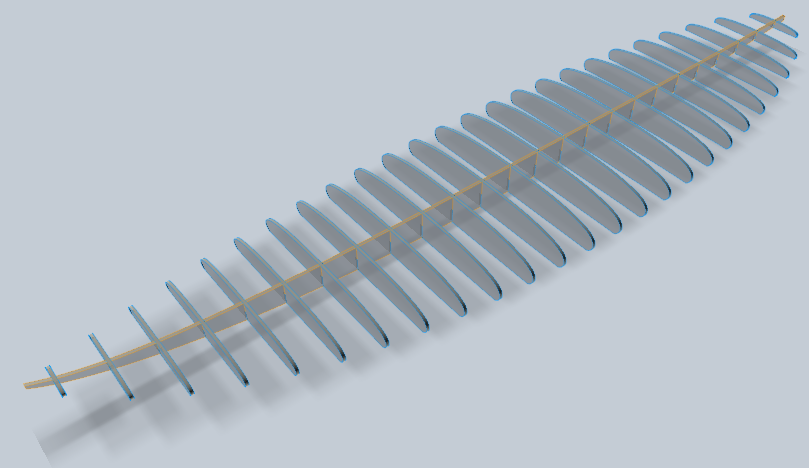

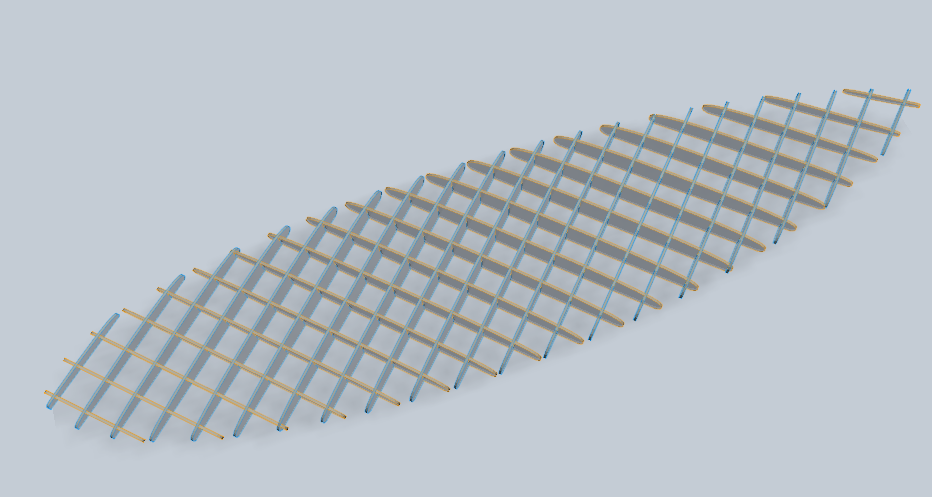

It does not need to be so finely detailed for almost any use...Thanks for the feedback. The thing is...it does! Origin of STL file is a CAD/CAM app designed to produce finely cut foam surfboard blanks, ready for extremely light final hand sanding (if any) then fiberglass. In the hydrodynamics of surfboards, fine detail is everything. After designing within this CAD/CAM tool, I simply export the resulting STL. Was trying to find a simple way to slice it up to gen internal structure components for laserCNC. This would allow for producing entire board out of wood, removing the need for foam completely. Thats why I looked to your Slicer plugin. Didn't want to have to do a bunch of re-work or dumb down the fine detail. Just looking to simplify my already challenging workflow.

@tig said:

I've left SolidSolver running on it that way, and I'll report back...

I may have found an alternative way...I ran the original STL thru the Online service of NetFabb. It returned a cleaned up STL that reported Solid in both TT's SolidInspector and SolidSolver. Success!

And its automated so I didn't have to do a bunch of additional work.Resulting STL file - Processed via NetFabb Online Service

And its automated so I didn't have to do a bunch of additional work.Resulting STL file - Processed via NetFabb Online Service

So now on to Slicer... SPLAT!@tig said:

Even if it becomes a manifold solid chances are that Slicer5 will balk at it !

Yep, SPLAT for me too. But I did find a solution and got it sliced, sorta. Just not using Slicer5...and I wanted to!

These images are from 123D Make. Nice app. Simple, powerful and very forgiving. Imported the original STL that had holes and folds and all the other problems reported from SolidSolver and Slicer. It just worked. Once sliced, 123dMake provides flat layout files ready for export in EPS, DFX, and PDF formats. Also provide resulting STL and OBJ files.Thank you TIG for looking at my challenge. I want to work in SketchUp as my post CAD/CAM Board designing tool. So many cool things I want to use for further "Frame" refinement and customer presentation. As of now, I can't use Slicer nor SolidSolution in this workflow. Maybe you and ThomThom could work together to refine these plugins (TT's UI and presentation and your hard scrub approach) to provide a more forgiving and thus more powerful/valuable solution. That's a plugin I'd pay for. Thanks again TIG for your continued contributions!

-

@tig said:

BugSplat after 20 mins !

Try making a simpler form...

Thanks Again TIG! Please see above response/request. I stand ready to help with Use Case and testing for any new developments.

KnottyRico ~ Wood-dent you rather ride knotty?

-

Hello all,

How do i manually fix nested instances or is there a plugin to help me?

-

@catramanthony said:

Hello all,

How do i manually fix nested instances or is there a plugin to help me?A 'container' can never be 'solid' if it contains nested component-instances or groups - even if those nested parts are themselves 'solid'.

To get a solid 'container' to include the nested parts' geometry, you must select the nested parts and explode them [context-menu] back into 'raw' geometry.

A manifold 'solid' component or group [aka 'container'] can only contain edges and faces - nothing else can be inside it - i.e. no non-geometry and nothing 'nested'.Every edge must support exactly two faces.

That means there can be no faceless edges, no holes/flaps/shelves where an edge has only one face, no internal partitions where an edge will have three or more faces, no forms which appear otherwise solid but share a common edge - like two touching cubes - where one shared edge has four or more faces.Also all of a solid's faces should be oriented 'outwards'.

Also a solid's forms cannot interpenetrate themselves - they might report as 'solid', but they will be unprintable in 3d !

To trap for this, once you think it's fixed and reporting 'solid' in Entity Info, edit it, select all and use the context-menu to intersect with selection - exit the edit, and if it ceases to report as 'solid', then you'll need to fix any issues as listed above - these will probably be internal partitions etc...

Advertisement