Have you built what you design in sketchup?

-

@unknownuser said:

@krisidious said:

if I'm not mistaken Jeff that's a pretty forward thinking skatepark. I don't think I've ever seen grinds like that. have you seen examples like it before? or is this your idea?

all my ideas.. but, i've been building ramps forever. my first paid job happened while i was still in high school and i've been doing it ever since.. (even did a couple of jobs in springfield

)

)

building the same stuff over and over gets boring so i'm always trying to come up with new shapes that remain functional..Really cool stuff, definitely don't forget to post the final results.

-

Some excellent, inpspiring stuff in here guys, thanks for sharing!

-

@chris fullmer said:

Jeff the top piece of plywood acts as a top form for the conrete, so it shapes the top surface? Sort of like inection molding concrete or something? How do you know the form is full?

chris, here's the process.. place, shape, finish..

i'll post another pic or two on the 26th when this thing gets lifted off the mold and placed..

-

beautiful... love the wet work. did you use fibermud?

-

That is awesome.

-

@krisidious said:

beautiful... love the wet work. did you use fibermud?

Nah, you can't put a super smooth finish on that stuff. This is a 5000psi shotcrete mix.

-

I figured durability would be more important... some of those corners worry me a bit. did you do work on the Springfield Skatepark?

-

@krisidious said:

I figured durability would be more important... some of those corners worry me a bit. did you do work on the Springfield Skatepark?

skateability comes first

.. nah, the stuff is way durable.

.. nah, the stuff is way durable.here's something along the same lines (from the link i posted earlier in the thread).. those corners are doing good and they don't have the steel border with rebar welded to it like this new one..

from around 50seconds to 3minutes

[flash=640,505:ndbkyfoj]http://www.youtube.com/v/HUhlCn0zz0A?fs=1&hl=en_US&rel=0&hd=1&color1=0x2b405b&color2=0x6b8ab6[/flash:ndbkyfoj]re:springfield.. no, i didn't work on the concrete park that you're talking about though my company did.. i'm a carpenter and build mostly indoor stuff out of wood.. i built the indoor park there around 10 years ago prior to them saving up enough dough for the concrete park..

i'm trying to take my wood bending skills to these concrete molds etc.. it's going to allow me to go into the direction i'd like which is more in the realm of public sculpture (that can be skated). -

We use SU heavily for a wide variety of product design, application and so on.

Pic of me, a brief article and a few SU indications of a few of the products.

A few years on and we still use it in much the same ways.

Karl

-

I think I've built pretty much everything I've designed in SU. From the little bits of model airplane landing gear through office furniture http://sketchup.google.com/3dwarehouse/search?uq=1259776282395917285925759&scoring=m all the way up to my new house http://www.rowledge.org/tim/building/index.html

-

HI all, designed and built this a few years ago. Didn't even know you could render an SU image then

You will need to scroll down on the last image

You will need to scroll down on the last image

-

I'm still new to sketchup, so I don't have much works realised. One thing is the renovation of my interior designshop:

-

I designed and built these bookcases as one of my first SU projects

http://forums.sketchucation.com/viewtopic.php?f=183&t=30924&p=271820#p271820

And also this woodworking bench.

http://forums.sketchucation.com/viewtopic.php?f=183&t=25804&p=254932#p254932

There are SKP's also. Jerry

-

A Sony shop I did last year - first the render

and the finished product

The total shop was completed in 7 weeks and we just barely made it on opening day. -

hey . . .the TV screens don't match the render.

-

@fastech370 said:

I designed and built these bookcases as one of my first SU projects

http://forums.sketchucation.com/viewtopic.php?f=183&t=30924&p=271820#p271820

And also this woodworking bench.

http://forums.sketchucation.com/viewtopic.php?f=183&t=25804&p=254932#p254932

There are SKP's also. Jerry

Those shelfs look great fastech370.

You are in a very select group here who has actually build what they modeled like the thread title says.

-

Form this old structure

...trough SU...

...to this.

-

This is my work, a church an the modell!

All other works are super!

-

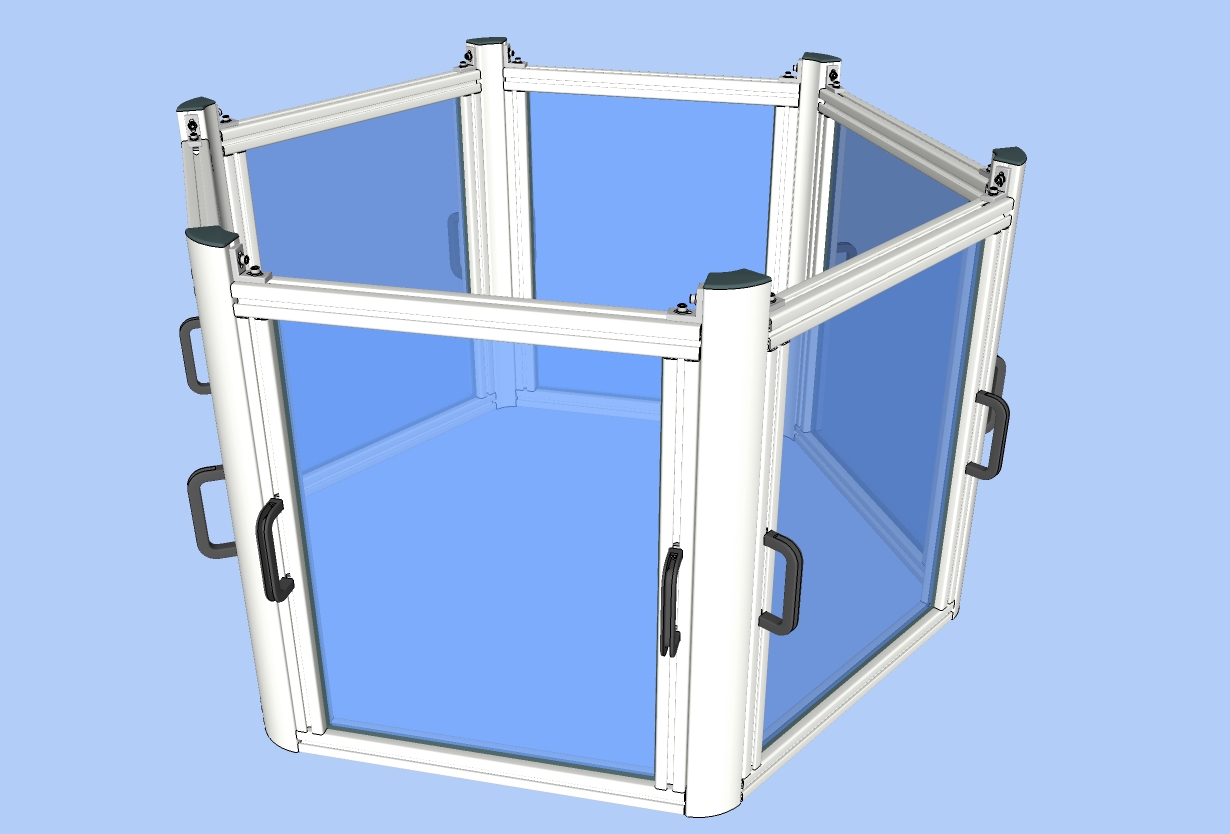

I have just ordered the components for the attached machine barrier. The building kit system is made by ITEM and I downloaded most of the parts as Google Sketchup files from http://www.traceparts.com/users/TracePartsOnline/index.asp. I have attached the .skp file for those interested in this type of building system.

Regards,

Bob

-

.

for those following.. i peeled this thing off the mold earlier today..

Advertisement