Rail & Stile Edge Routing

-

Michael,

Have a look at the attached SKP and the instructions here. Click on the scene tabs to follow along. Maybe it'll help clarify.

-

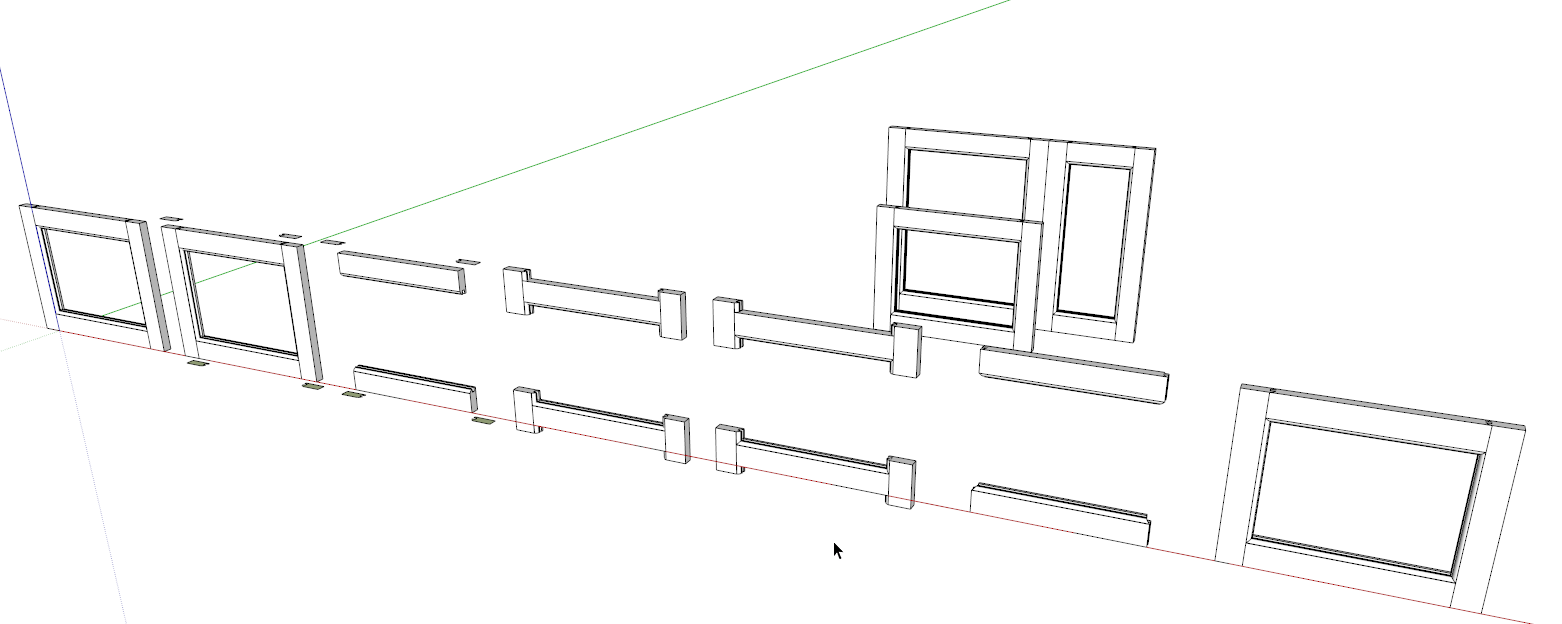

Rails and stiles drawn and placed in proper relationship to each other. The parts are components. The topped rail is a flipped (not rotated end for end) copy of the bottom and the right side stile is a flipped copy (again, not rotated end for end) of the left.

-

Open a stile for editing, select the end face and its edges using a double click of the Select tool. Use Move/Copy to copy the face up a bit away from the end of the stile. While the copy of the face is still selected, hit Ctrl+X (Command-X on Mac) for Cut. Open the top rail for editing and choose Edit>Paste in place. Use Move/Copy to copy the face to the opposite end of the rail and use Flip Along to flip the newest copy. Make sure this copy is in the correct position above the end of the rail. These faces will form the cope cutter for the rails and just like working with the rail and stile cutters in the shop, if the cutter isn't located correctly, you'll get a lousy joint.

-

Hide the stiles for the time being.

-

Open the rail component for editing again and use Push/Pull to push the cutters through the ends of the rails.

-

Notice there are no intersections where the faces on the "cutter" pass through the rail.

-

Select all of the geometry in the rail component including the cutters. Right click on it and choose Intersect Faces>With Selection.

-

Erase what is rail and correct any reversed faces. The rails are finished.

-

Unhide the stiles.

-

The thing about reusing the rails and stiles is correct and you can make them any length you need. Push/Pull will work on the stiles but not on the ends of the rails. Instead, use the Move tool. Open the rail component for editing, drag a left to right selection fence around the end of the rail. Get the Move tool and move the selection in the required direction and for the required distance. Make sure if you've got more doors to make that you are using Make Unique on pairs of like components. In this last scene, all three door frames are from the original components. If you would use this rail and stile again, save these components so you don't have to redraw them.

-

-

Thanks very much! I understand now how to use the rails you made for any project. Still working on making my own however and getting them to intersect. Thanks again!

-Mike

-

Maybe you could post what you've got or send it by PM with a note about where you're getting hung up?

-

Hey it worked! I think I've figured it all out. Just need to practice a bit until I feel comfortable. I've been working with sketchup for about 5 years now designing furniture and its probably one of the best tools in my shop. I just discovered this resource so I'm sure I'll be posting questions. What a great site! Thanks again for your help.

-Mike

-

-

Yeah that might be next on my list!

Advertisement