[Plugin] Milling Tools

-

Work in Progress - Alpha version

This is just a WIP preview.Based a request for a milling tool plugin: http://forums.sketchucation.com/viewtopic.php?f=323%26amp;t=24588

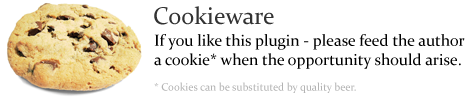

Creates Dog-Bone fillets on the faces you click on.

Use VCB to set tool radius.

Use VCB to set arc segment quality. ("8s" will make arcs based on circles with 8 segments)The face clicked on should not be connected to any other faces or edges.

Version 0.2.1a

-

Better internal processing of existing fillets.

Version 0.2.0a -

Handles previously processed faces.

To do:

- Validate face before processing.

- Per-corner processing

- T-Bone fillets

- Remember tool settings

SketchUp Plugins | PluginStore | SketchUcation

SketchUp Plugin and Extension Store by SketchUcation provides free downloads of hundreds of SketchUp extensions and plugins

(sketchucation.com)

-

-

I have found two omissions:

1, select the faces necessary for the positive and negative behavior will be crash

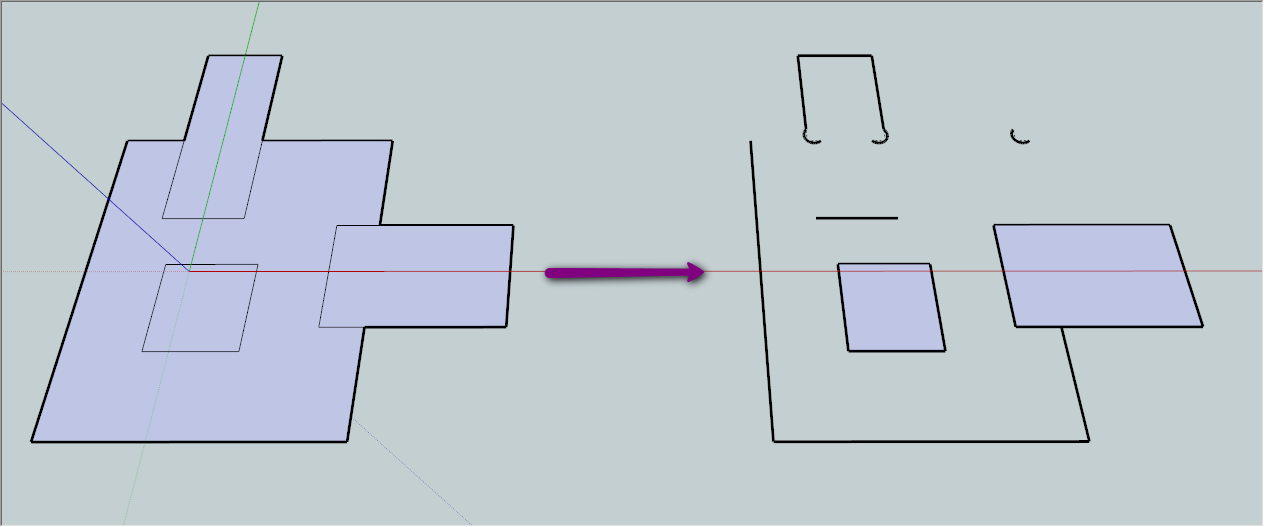

2, two face intersecting must be four points, five points, there will be non-operational status

-

@hsjzyangbin said:

I have found two omissions:

1, select the faces necessary for the positive and negative behavior will be crash

2, two face intersecting must be four points, five points, there will be non-operational statusIt does not work on pre-selected faces.

And as stated in the description:@unknownuser said:

The face clicked on should not be connected to any other faces or edges.

You should only apply this plugin to single faces that doesn't touch anything else. The face can have holes though.

@hsjzyangbin said:

1, select the faces necessary for the positive and negative behavior will be crash

SU bugsplatted?

-

Update

- Edits existing fillets.

-

Update:

- Better internal processing of existing fillets.

-

Hey Thomthom

this is looking really good right on track for milling tools for use with sketchup

can you email me as i would like to talk with you about a really cool project i am working on that may interest youthanks

keep up the great work!

Join the Evolution !

-

A new task!

-

is there no more development for this plugin ?

-

I've been ill for more than a week.

All work has been halted.

All work has been halted. -

oh sorry

hope you get well soon

-

I've pretty much recovered - but I now got a bit of backlog of work to do. I'll get back to this plugin - just need to catch up.

-

this plugin has a lot of use! please continue development.

thanks

-

Just out of curiosity, is this in any way related to Fredo6's Bezier tools added polyline tools for dogbone and t-bone polylines? And was work discontinued for that reason?

-

@mitcorb said:

Just out of curiosity, is this in any way related to Fredo6's Bezier tools added polyline tools for dogbone and t-bone polylines? And was work discontinued for that reason?

The tools where done in parallel - initiated by a request here at the forum.

I simply haven't had time to work on this. Since I don't do CNC work myself it'd ended up as low priority. -

I don't do CNC work either. I was just thinking maybe Fredo's feature could fill a temporary need? They are obviously different approaches.

-

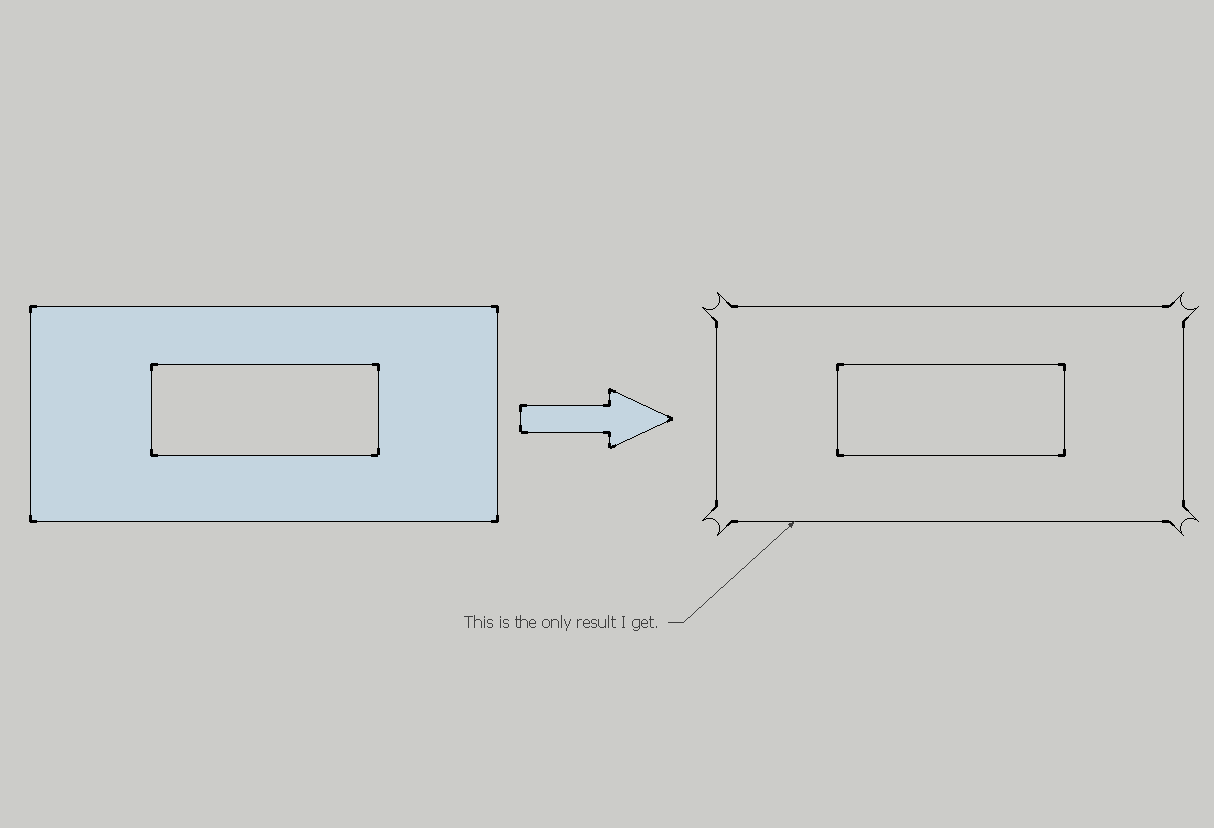

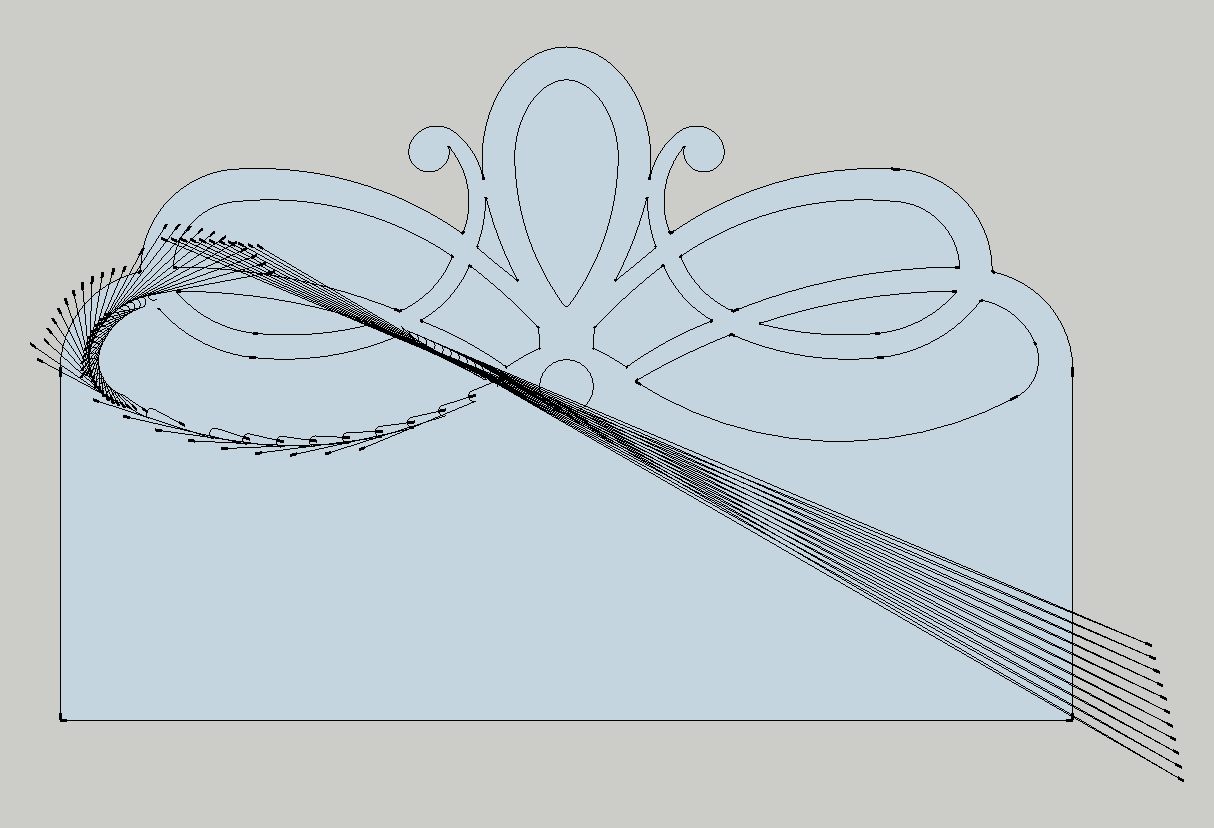

I encounter problems with this model. I also tried on a simple rectangle and I get strange results. Maybe I don't know how to use it?

It would be useful to get the actual contour line and this plugin to create a path (inner/centered/outer) on how the milling head will perform. In the first post, I've seen some images that illustrate exactly this, but my results were bad.

- I don't know why "Milling result.png" is not shown

- I don't know why "Milling result.png" is not shown

-

In your attached model, there are errors listed in the Ruby Console. The plugin has not been tested on such complex and curved shapes.

@unknownuser said:

It would be useful to get the actual contour line and this plugin to create a path (inner/centered/outer) on how the milling head will perform. In the first post, I've seen some images that illustrate exactly this, but my results were bad.

You would like the path you see in the preview as actual geometry?

-

This model if yours has revealed several issues with this plugin...

-

@thomthom said:

You would like the path you see in the preview as actual geometry?

I would like to draw the actual geometry in Sketchup, but the plugin to alter my edges (offset/inset or leave them unaltered, just fillet corners). Because the milling bit can perform on the left, on the right or on the center of the line.

This plugin could be a very powerful one in the future... (offtopic: Now I have some problems with DXF export from SketchUp and importing in CNC software. Some line elements (especially arcs) are mirrored outside of board perimeter). Maybe AutoCAD and SketchUp export DXF in different manners.)

-

@thomthom said:

This model if yours has revealed several issues with this plugin...

It's my model...actually is something I do now. The curves have a lot of segments because it will be sent to CNC and I have some problems with arcs in DXF export. Polylines are ok, but if there are less segments, it will reflect in manufactured piece.

Advertisement