Solid objects?

-

Often SU "say" the PP is limited to a certain point. It is always due to some connected geometry within the same context. In these cases (even temporarily) grouping sometimes just a face only to PP it through some "offending" geometry is a good tactic.

-

I think that is what I'm looking for - the ability to move an object, until it is no longer able to move due to the physical limit of the object, as it would in real world objects.

In other words, to be able to slide the slot of one piece into the slot of another piece, until both slots are at their limit, and the pieces are in the position.

A more elaborate way of using this application might be to build, piece by piece - such as taking SketchUp 2x4 studs, "cut them to length", and then "nail" them in place, to build a wall, and then cover that wall with SketchUp pieces of drywall.

With something like this, a construction project can be built a piece at a time, until project completion and one could see where problems in construction would occur before actual building started, due to the "electronic" pieces having actual physical limits to which they have to adhere to.

-

Seems you can make that with SketchyPhysics3

But with some add little part of coding from you

-

Collision detection is actually coded somewhere in SU (as while using the Walkthrough tool, there is collision detection) so I can indeed imagine a pőlugin using this function - if it is available through ruby at all, of course.

But this is where my co-operation ends here as I know nothing of scripting - but at lest welcome to SCF if I am not too late with this.

-

I have just realized Chopper's question could be the inspiration for one of the coolest plug-ins ever: "Move Things Around With Collision Detection Activated"

I have just realized Chopper's question could be the inspiration for one of the coolest plug-ins ever: "Move Things Around With Collision Detection Activated" -

@unknownuser said:

Seems you can make that with SketchyPhysics3

But with some add little part of coding from you

I know next to nothing about programing - especially anything more than old fashion Basic, and I have forgotten almost all of that ( last time I did any programming was ~25 yrs ago )

.

. -

@chopper greg said:

I think that is what I'm looking for - the ability to move an object, until it is no longer able to move due to the physical limit of the object, as it would in real world objects.

In other words, to be able to slide the slot of one piece into the slot of another piece, until both slots are at their limit, and the pieces are in the position.

A more elaborate way of using this application might be to build, piece by piece - such as taking SketchUp 2x4 studs, "cut them to length", and then "nail" them in place, to build a wall, and then cover that wall with SketchUp pieces of drywall.

With something like this, a construction project can be built a piece at a time, until project completion and one could see where problems in construction would occur before actual building started, due to the "electronic" pieces having actual physical limits to which they have to adhere to.

maybe i'm missing something but what you're describing you want to do in this post is fully possible using only SU and it's most basic tools.

do you have a very specific problem that you're running into because SU is a surface modeler? (attach a .skp showing the problem if you can)..

-

I don't think this can be done in SketchUp - but I wish it could.

I'm a stairbuilder and I use SketchUp to lay out parts for the shop to cut. Often my stairs are very complicated and I'd like a Ruby that either didn't allow two (or more) objects to intersect one another or, that the intersecting areas would change color to red or something visible so I could 'see' that two of my parts are overlapping.

When I get to a situation where I've got a newel post and a curved tread and curved stringer and a riser, etc. all meeting at one place, it's very easy to not see that something is intersecting with something else - until my assistant starts complaining after cutting material and finding it doesn't work the way I told him it would. Going to wireframe or xray doesn't help.

Ideally I'd like to be able to go to wireframe and see red shapes wherever two objects intersected.

-

@unknownuser said:

maybe i'm missing something but what you're describing you want to do in this post is fully possible using only SU and it's most basic tools.

I don't think it is - I have tried to, but always end up pushing an object through another or one object sticks to the other.

-

@chopper greg said:

I don't think it is - I have tried to, but always end up pushing an object through another or one object sticks to the other.

i was talking about the situation you described (stud wall w/ drywall).. really don't see a need for solids there..

in more complex situations such as arail is describing can get a little more confusing because complex joinery and or/multiple complex parts converging at one point can get out of hand even with xray and zooming..

i requested some intersect tools here:

http://forums.sketchucation.com/viewtopic.php?f=180&t=22641the idea about having color coded warnings with overlaps would fit in nicely in that hypothetical toolset.. the core function of that plugin is finding an overlap and deciding what to do with it.. in that thread i asked to have parts erased but there could also be an option to color instead of deleting.

-

I just see it as an extension ( granted extreme simplification of the idea ) of being able to make and test fit parts together electronically, before they are actually made in real life.

-

@chopper greg said:

...always end up pushing an object through another or one object sticks to the other.

Now thatpart could be overcome by using groups/components.

-

excuse my opinion but if you need to place all studs then drywall ... in SU before you build it you have no business building anything! if you need to build machined parts and put them together for something like a pump for example, then use Solidworks or something similiar. besides inferencing and careful design work should be totally capable of keeping you out of trouble. IMHO

-

@xrok1 said:

excuse my opinion but if you need to place all studs then drywall ... in SU before you build it you have no business building anything! if you need to build machined parts and put them together for something like a pump for example, then use Solidworks or something similiar. besides inferencing and careful design work should be totally capable of keeping you out of trouble. IMHO

With due respect, that is not very nice.

No one starts off as a Norm Abram, nor can everyone afford the likes of solidworks or do they have the skill to use it.

Pre-building, even basic items, will point out any problems and allow people to properly plan. As such the ability to cut and test fit everything beforehand would be of great use to make sure that the design they hand in mind is valid, but to do that, your objects need to act as solids. We have heard from another poster, that even professionals do not always get their designs so that it will work in real life, until after the cutting has begun.

Such pre-building would allow, all the cutting and fitting to be done long before anyone putts their hand on a saw, thus would be of use to anyone including non-professionals, allowing any object that could be made with SketchUp's simple push-pull system to be test built, with inexpensive electrons and not expensive real world materials.

-

I would think that a little more than a warning dialog would be of greater use - like highlighting the area ( or area's ) that has intersection occurring, even then that might be less functional than allowing full contact but no penetration of an object on another object - like a 5mm OD peg not quite fitting into a 5mm ID hole.

-

@chopper greg said:

Such pre-building would allow, all the cutting and fitting to be done long before anyone putts their hand on a saw, thus would be of use to anyone including non-professionals, allowing any object that could be made with SketchUp's simple push-pull system to be test built, with inexpensive electrons and not expensive real world materials.

thing is, everything you're asking for (well, except for the solids thing) is possible in sketchup.. i do it often with some weird stuff so i know it works.. it might just be a simple change of mindset to accomplish what you want.. don't fight the software.. realize what it can do for you and go with that..

-

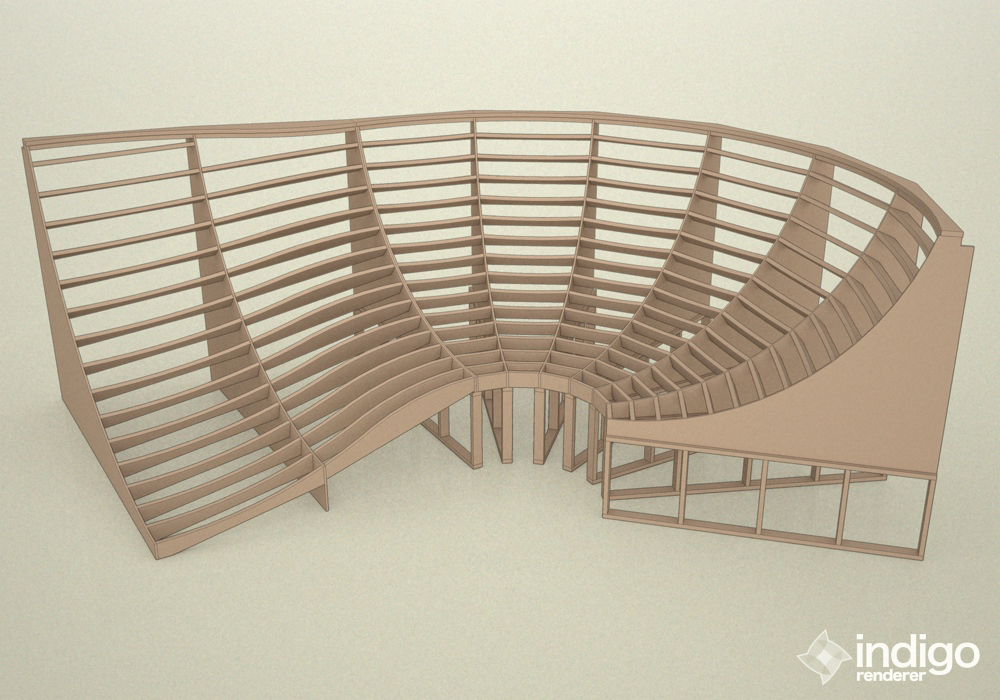

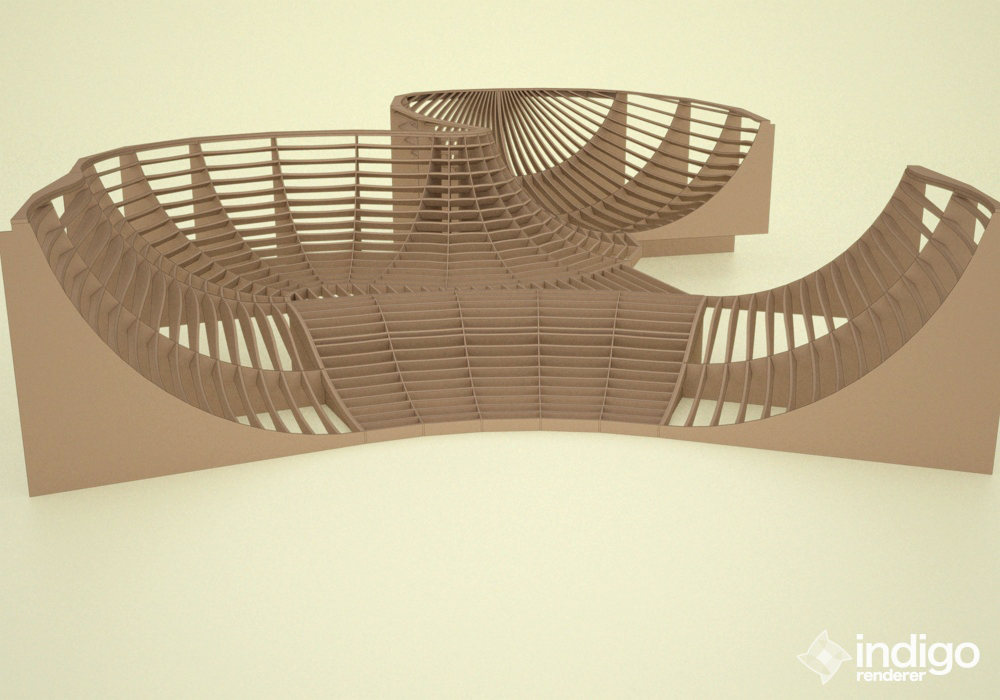

more of that bowl..

[fwiw, i've built a lot of stuff like this in the past and this drawing is the first time i'm actually drawing the entire frame.. i usually only get this detailed on very specific complex sections and the rest is done out of the head.. i'm only drawing this for a big promo print... if you're new to carpentry, welcome!.. pre-visualization is a great thing for successful projects and i suggest practicing it mentally as well as electronically]

-

@chopper greg said:

I would think that a little more than a warning dialog would be of greater use - like highlighting the area ( or area's ) that has intersection occurring, even then that might be less functional than allowing full contact but no penetration of an object on another object - like a 5mm OD peg not quite fitting into a 5mm ID hole.

I do not think you realize what a complex thing it is you ask Greg.

I have many years of Solidmodeling under my belt with most of the popular true solid modelers (Solidworks, Inventor, Intergraph, Unigraphics, Etc...) I can tell you that none of them implement what you describe in any usable way.Solidworks can do motion. You can add 'Mates' between solid parts. This allows them to pivot, slide, hinge and quite a bit more. They even added virtual motors both radial and linear. With some fancy footwork they can simulate belts and gears, in the latter case it doesn't work by virtual friction or surfaces impacting other surfaces. The point I'm getting at is that with all this parts can still intersect and pass through each other.

There once was a third party product ... I think it was called Solidmotion that we bought. It did motion studies and could do what you talk about but not in real time. You setup the parameters and let it run overnight. It built a slide show that you could animate and see the results. (Wasn't terribly useful)

This sort of thing requires a lot of horsepower.

Perhaps Simple alignment mates could be added to Sketch up. I can see that working. You would select a face on each of two parts then apply a coincident mate. The loose part moves to that position.

Three Mates and your parts are locked where you want them to be.I am getting Solidworks 2010 end of this month. I'll let you know what new stuff they added.

-

you could try booltools and just build with dimensional lumber and then use the difference tool to trim away anything that laps or intersects. that way when you measure the resulting parts they can't possibly not fit together properly.

-

@unknownuser said:

thing is, everything you're asking for (well, except for the solids thing) is possible in sketchup.. i do it often with some weird stuff so i know it works.. it might just be a simple change of mindset to accomplish what you want.. don't fight the software.. realize what it can do for you and go with that..

That's just it, I am trying, but because the object are not acting as solid individual pieces, they end up shoved through another piece or worse - they stick to each other and when I test fit I end up pulling the parts totally out of shape.

I have heard that making each part a group, would help in this regard, but the tutorial about groups is less than crystal clear and I find my self getting more and more frustrated with it.

@unknownuser said:

[fwiw, i've built a lot of stuff like this in the past and this drawing is the first time i'm actually drawing the entire frame.. i usually only get this detailed on very specific complex sections and the rest is done out of the head.. i'm only drawing this for a big promo print... if you're new to carpentry, welcome!.. pre-visualization is a great thing for successful projects and i suggest practicing it mentally as well as electronically]

Yes, I'm fairly new to carpentry - and as such, while I know what I would like to accomplish, I do not know how to do it, and as such I tend to end up wasting a fair amount of material.

Thus the reason I would like to be able to cut and fit with electrons rather than the real stuff.

Thus the reason I would like to be able to cut and fit with electrons rather than the real stuff.@gruff said:

I do not think you realize what a complex thing it is you ask Greg.

I have many years of Solidmodeling under my belt with most of the popular true solid modelers (Solidworks, Inventor, Intergraph, Unigraphics, Etc...) I can tell you that none of them implement what you describe in any usable way.Solidworks can do motion. You can add 'Mates' between solid parts. This allows them to pivot, slide, hinge and quite a bit more. They even added virtual motors both radial and linear. With some fancy footwork they can simulate belts and gears, in the latter case it doesn't work by virtual friction or surfaces impacting other surfaces. The point I'm getting at is that with all this parts can still intersect and pass through each other.

I think that there is some misunderstanding - I don't have allot of need for automation within the program - I can move a part myself were I want it to go, I just need to know when one part will not fit another, without being pushed into or through the surface and I have not been able to achieve that with SU..

@gruff said:

Perhaps Simple alignment mates could be added to Sketch up. I can see that working. You would select a face on each of two parts then apply a coincident mate. The loose part moves to that position.

Three Mates and your parts are locked where you want them to be.If I am understanding it correctly - this might work from my purposes.

@xrok1 said:

you could try booltools and just build with dimensional lumber and then use the difference tool to trim away anything that laps or intersects. that way when you measure the resulting parts they can't possibly not fit together properly.

booltools?

I have not heard of it - I tried looking it up and I'm finding allot of references ( about 4,600 hits ), but not hard data about what it actually does, it could be that I'm just missing it among all the references.

Advertisement