Latest Work with Curved Roof Design

-

Here's another of Shuhei's "bubbletecture" projects:

http://www.designboom.com/weblog/cat/9/view/5299/bubbletecture-m-maihara-kindergarten-by-shuhei-endo.htmlIn Google Search, "bubbletecture" reveals much of his work.

Taff

-

New Zeeland Aikido Dojo inspired by Bucky. Thing is that we still have to walk on horizontal surfaces

-

Taff,

Wow! Thanks so much for the links. Endo Shuhei's structures are the closest thing I've seen to what I'm trying to build in terms of his use of irregular triangles. I'd love to know more about the hubs in the two buildings you linked to. From the pictures it looks like he used different approaches in each building. I'm honestly not terribly thrilled with the exteriors of either building but the interiors are stunning.

Regarding Billy Woods hub design. I tried to contact Woods to see if he still had any kits for sale, or would just be willing to have a conversation. I never heard back from him. I definitely like his approach though. One big difference in my version is that all the hub pipes are vertical. This is possible because I'm working toward curved roofs, not domes. Using all vertical hubs solves a number of problems, including making it much easier to connect the roof to vertical walls.

Taff, I was pretty impressed with how strong the framing was without the skin. The plywood has tightened everything up, but the framing itself has its own structural integrity. I think it goes back to triangles being inherently undeformable shapes.

Anyway, thanks again for all the links. I've downloaded the Domebook 2 pdf and will peruse over the next week.

The help provided on this forum never ceases to amaze.

Fred

-

to amaze me¡

Thanks Fred -

@fbartels said:

I tried to contact Woods to see if he still had any kits for sale, or would just be willing to have a conversation. I never heard back from him.

Well, Dyna Domes has been out-of-business for some time now. Last I heard (Dec 2008,) Bill Woods was retired, in Buckeye, Arizona.

-

Fred,

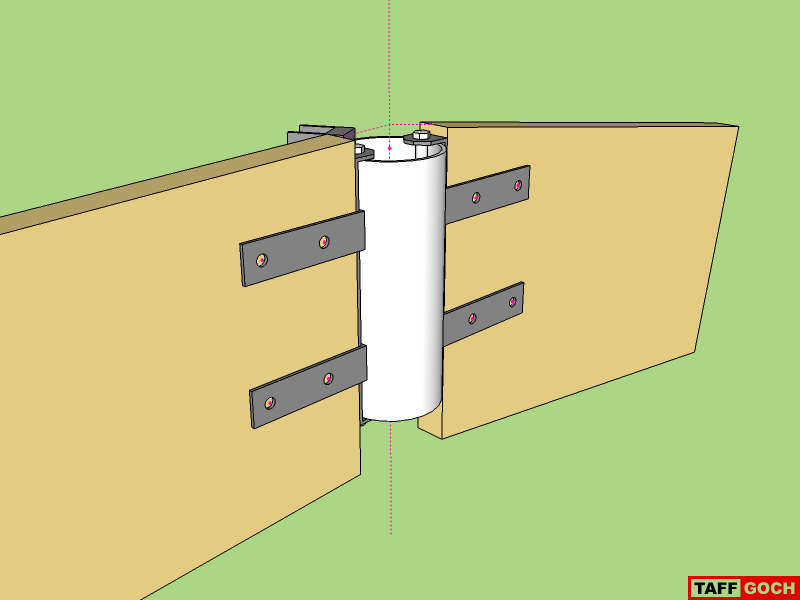

This connector is composed of 3 pieces of "strap" steel stock, requiring only bending and drilling (no casting.) All connectors are identical, with no custom angle restrictions.

(A modification of one of the patent connectors, to make DIY easier, with no welding, although it can be welded, if desired.)

The wood struts are connected to the straps first, using wood screws in the ends, and bolts all the way through the faces. Final assembly is completed by positioning on the hub pipe, and inserting the long hub bolts.

-

Taff, I do believe connectors like that would work. Very clever. Simple, flexible, and probably relatively easy to produce after working up a few jigs. I would guess you can get strap steel stock at Home Depot if one wanted to make a prototype?

-

Is that a PVC cilinder in the middle?

Wouldn't that be a weak spot in the construction? -

@kwistenbiebel said:

Is that a PVC cilinder in the middle?

Wouldn't that be a weak spot in the construction?Looks like PVC but we are thinking steel.

-

Fred,

If you're going to model with the connector I modeled, you should move the two stut "u-straps" as far up, and as far down, as possible. I modeled them in more central positions, to ensure that they wouldn't interfere with skinning.

The bottom strap can probably be (would best be) moved all the way down, without ever having to be subsequently moved.

The top strap should be positioned as high as possible, without "poking" above the top surface of the strut.

A "shorter" hub pipe would permit central positioning on the end of the strut, with the strut-straps at the top-most and bottom-most positions, all the time.

I'm thinking tension forces, not compression forces. Compression would push the strut against the hub, and all's okay. Tension, however, would pull the strut away from the hub. If the strut U-straps are more-centrally located, the hub-strap could bend. If the strut straps are positioned at the extreme upper/lower locations, bending of the hub-strap should be ruled out.

(I would have modeled that way, had I thought of the tension-force potential earlier.)

Taff

-

seems to me this would be simpler and maybe even stronger?

-

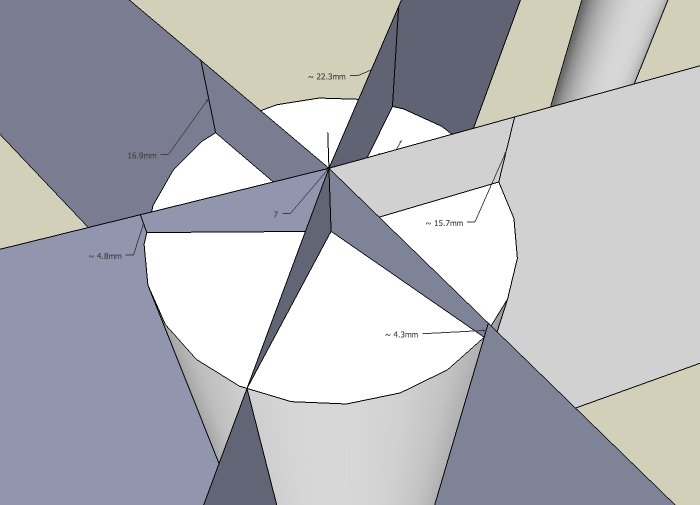

xrok, the major problem with your approach is that the triangles forming the roof surface actually intersect over the center of the pipe, and to make this happen the beams need to attach to the pipe circumference at different heights from the top of the pipe. The attached images should help to make this clearer. Fred

-

could you not cut the top of the pipe at an angle?

or slot the lumber:

-

how can it be simple when it looks like you would need a degree to figure out those non uniform triangles?

how can it be simple when it looks like you would need a degree to figure out those non uniform triangles?anyway, all the best with your project.

-

xrok1, Some interesting ideas! There are obviously multiple ways to solve this problem. What I'm aiming for is hub hardware that is simple, easy to work with, and strong. Your ideas are definitely heading in that direction. Fred

-

Fred,

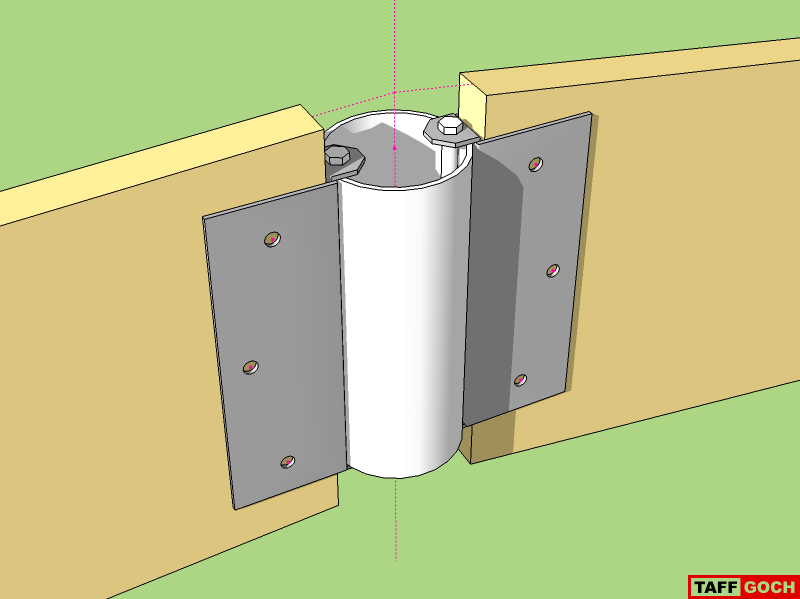

Further simplification, using thinner galvanized plate (the same stuff of which joist hangers are made.)

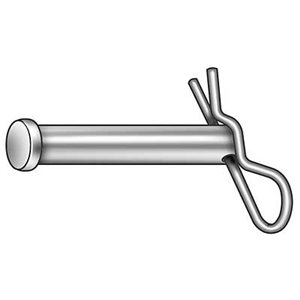

The bolt can be more-simply replaced with a long clevis-pin, making assembly much easier/faster (possibly cheaper, too.)

This is pretty close to your original connector design, and can be bent, using a jig and hydraulic press (jack) or vise & hammer. Since it's made of "plate" material, it doesn't have to be as thick as the straps in my first model. Additionally, it permits a more intimate strut-to-pipe fit.Taff

-

xrok1,

Those tiger-grain oak struts should provide for a very impressive (and expensive) ceiling !

-

thats all i could find in the garage!

-

Taff,

Nice clean simple design. Now we just need to get it manufactured in volume. If you get a patent then Simpson will consider.

Fred

-

Maybe useable...

http://www.strongtie.com/products/connectors/bc.asp

if pilot hole is used with bolt, sure you should not, but I think it this case it wount be an issue.

Advertisement