Over Engineering for My Shop

-

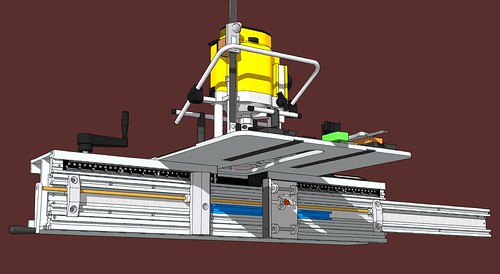

Not directly woodworking but related. Thought I'd show something I've been doodling with as an "improvement" to one of the tools in my shop. Actually the tool doesn't need it but I'm not letting that get in the way. This is the Router Boss which I find to be more useful than my router table. Actually the router table comes in handy with my Porter Cable OSS.

The crank on the top moves the long bar on the front left or right. There's normally a clamping arrangement to secure the work and by turning the crank you can move the work past the router. It works very well and there's no risk of getting your fleshy bits into the cutter.

I've been designing a fine screw advance setup which is still very much a work in progress. With the current design one turn of the crank on the left end would move the work 1/16 in. I'm thinking this will be nice for doing very small joinery for things like jewelry boxes. I made a proof of concept version the other day and it worked pretty well but I don't have the lead screw so I substituted a piece of standard threaded rod. Trying to decide at this point if I should order the hardware I need. Precision lead screw stock and associated nuts ain't cheap.

-

Very cool. Looks to be better than a horizontal mortiser or an X-Y-Z contraption.

-

I like the Router Boss for a number of reasons. It's extremely versatile, unlike a router table you can see what is going on, and it is safe. It's also mounted on the wall so it doesn't take up any bench space. Probably the key advantage to a horizontal mortiser over the Router Boss is in handling very long pieces like bed rails. As long as you properly support the work you could easily mortise the ends of the rails for the hook plates. I've got my Router Boss set up so there's about 42 inches of clearance under the router plate. That would make for a pretty short bed.

-

Say Dave, I assumed you didn't have a shop because I never see you post any of your shop builds?

Have you or am I just getting old and forgetful?

that's an impressive router boss model!

-

I do have a shop, Joe. It's been awhile since I've had much time to do anything in it and due to recent events on my wife's side of the family the shop had been congested with stuff waiting to get distributed to other family. Now I'm starting to get my shop back. I don't have a lot of photos of things I've built over the years but here are a couple of them.

The Router Boss model was originally done a few years ago. It was used for assembly and set up instructions. If you go to chipsfly.com, you can see some of those documents in PDF form.

-

Did you build that gaff rig boat Dave! I was a sailor for many years, helped build a 50' ferro cement schooner, and our family's 52" Horstman trimaran in 1968 which my parents sold in 1975 damn it!

-

Yep. Built from scratch.

-

perfect work(s)

and how cool are your reports with the sailboats (which is my only term for all these types ) - for one who lives in the middle of the continent, away from any coasts this is so very exotic !!

) - for one who lives in the middle of the continent, away from any coasts this is so very exotic !! -

Thank you HornOxx. The baby cradle is a Pram that I designed for my son. He just turned 16 last Saturday.

-

Great model and pictures. I love that gaff rig.

-

Thank you Peter.

-

... wunderbar, respect !!! (and a little bit of envy when it comes to sailing

)

) -

You could still build a boat and take it to some water to sail. The building process is a good learning experience.

-

The building process is a good learning experience.

The way having shingles is a good medical experience?

Boats have too many curves for me. -

LOL!

Boats teach you how to deal with things when you have no square corners.

-

as you can already guess - I am not a woodworker.

Can you buy a wood-shape-bender (a real one analog with plug) in a specialized shop?I'm just kidding here - as someone who can't even glue together any airfix model flawless I bow to this craftsmanship! - in addition a craftsmanship with which you can send your own son onto/into(?) the deep water without any stomach rumbling...

-

@hornoxx said:

as you can already guess - I am not a woodworker.Maybe you start a new hobby.

@hornoxx said:

Can you buy a wood-shape-bender (a real one analog with plug) in a specialized shop?

I expect you can buy a steam box although most people who steam bend wood would probably make their own. You can buy big clamps to use for clamping wood to forms. In the case of the two boats I show, the bending didn't really require anything special. The sailboat has a plywood hull. The bottom (12mm thick) was screwed down to the keep to create its bend. The deck is suspended at the ends with some intermediate bulkheads and then the sides were screwed to the edges of the deck and bottom creating their curves.

The small boat was built by bending the wood over a form. The planks on the small boat are only about 2.5 to 3 mm thick.

@hornoxx said:

I'm just kidding here - as someone who can't even glue together any airfix model flawless I bow to this craftsmanship! - in addition a craftsmanship with which you can send your own son onto/into(?) the deep water without any stomach rumbling...

Thank you very much. I think anyone could do this stuff if they just put their mind to it. When I was building the sailboat I had a number of people ask me, "How do you know how to build a sailboat?" The answer was that I didn't know how to build a sailboat but I knew how to do the next step in the process and could follow the directions.

-

@hornoxx said:

Can you buy a wood-shape-bender (a real one analog with plug) in a specialized shop?

@dave r said:

I expect you can buy a steam box although most people who steam bend wood would probably make their own.

Dave's undoubtedly correct that (most) pros build their own steam-bending set-up, but Rockler does sell this kit (along with plans for the box itself) for hobbyists:

Rockler Steam Bending Kit w/FREE Steam Box Plan, Hinges and Latch

All the hardware and fittings you need to bend wood to your will, including a steamer and a plan for building your own box.

https://www.rockler.com/ (www.rockler.com)

Advertisement