Medeek Wall Plugin

-

I've been looking at some screen shots from Chief Architect and giving some thought to framed opening headers and their trimmers.

Beyond the myriad of options I am already providing for window and door headers I may need to extend the list to a few others.

The current list is:

4X4

4X6

4X8

4X10

4X12

6X4

6X6

6X8

6X10

6X12

(2) 2X4

(2) 2X6

(2) 2X8

(2) 2X10

(2) 2X12

(3) 2X8

(3) 2X10

(3) 2X12

1-3/4X7-1/4 LSL

1-3/4X9-1/4 LSL

(2) 1-3/4X7-1/4 LSL

(2) 1-3/4X9-1/4 LSLFor larger doors (garage doors) glulams are fairly typical in my neck of the woods. If the designer selects glulam an additional menu will pop up that allow for the selection of the exact glulam size. I've already implemented a similar feature in the Truss Plugin for glulam rafter roofs.

I think it might also be interesting to provide an auto calculate feature based on the width of the framed opening:

- AUTO GLULAM

- AUTO 2X

- AUTO 4X

- AUTO 6X

- AUTO LSL

This is not an exact engineering solution since we don't know the loads on the header but it could at least get it ball park. Future releases of the plugin will have more engineering capabilities added so that one can actually run the actual numbers on a header (I'm think Forte type software here, one that I commonly use in my own practice).

Along the same lines another parameter should be added into the global settings to allows for auto-calculation of the door/window trimmer qty., again this would be based off of the width of the framed opening and also factor in whether the wall is an interior or exterior wall.

-

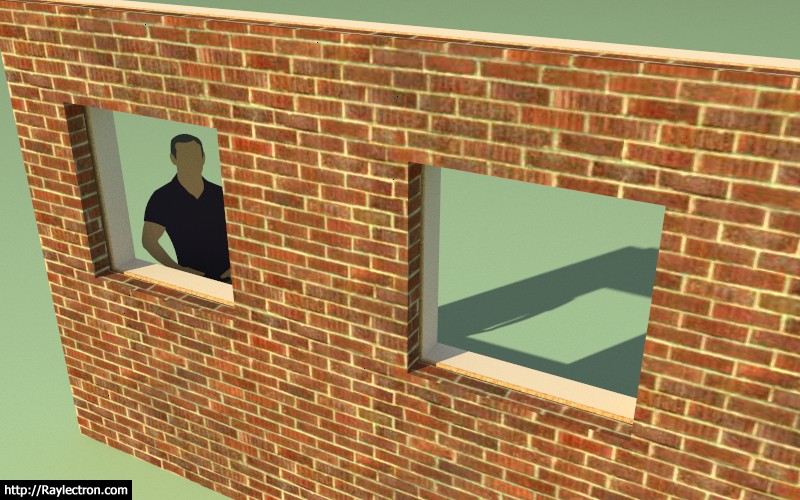

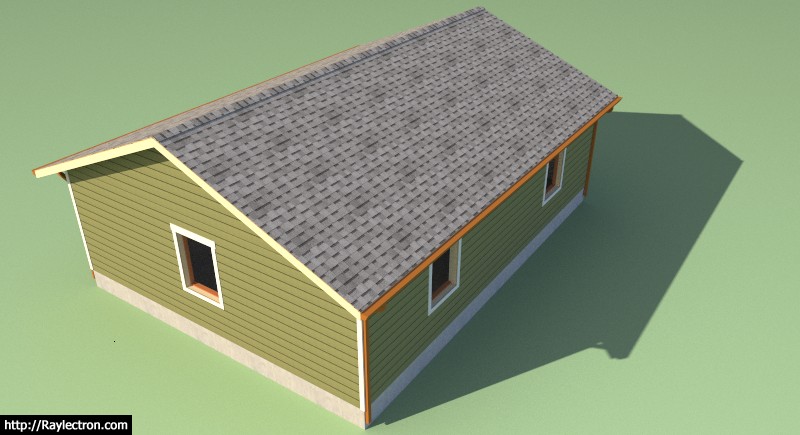

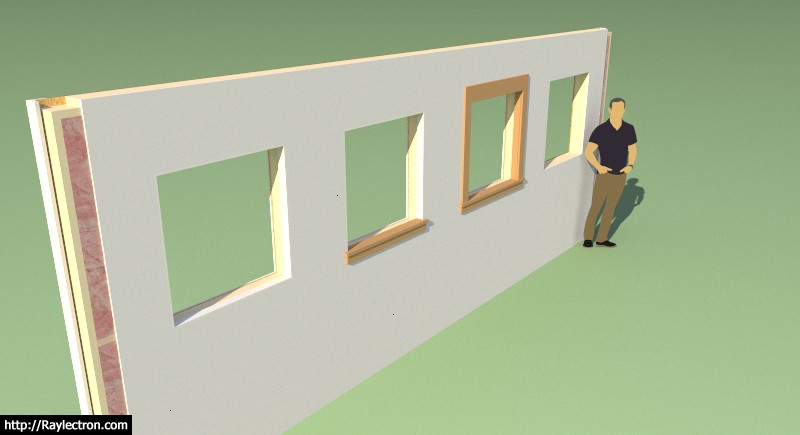

Another preview showing the insertion of windows and some other features:

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

It's looking really good — great progress!

I hope once you have all of the functionality coded, you will consider (in a future version) a second input method for generating walls and their openings: from the faces of massed walls.

It would fit more easily into our workflow, since we always have a massed model before elaborating structural and finish detail, so that walls and windows are already fully defined in size, position and orientation.

As is, it is definitely a huge step forward and I'm looking forward to your finished version one.

-

I'm only about 2-1/2 weeks into the actual development of this plugin so realize that I've only just scratched the surface. With the latest preview video I am getting a lot of questions about other wall systems. Initially I will release the plugin with the conventional light wood framing but subsequent developments will also look at steel framing, CMU, brick and other more exotic methods as the demand arises.

The framing option will currently be:

- Yes/No/2D

This will probably be expanded to (or some other variation):

- Lumber/Steel/CMU/None/2D/etc...

I still have a lot of work to do before I can release this even to the beta testers.

The current pre-release "todo" list is:

1.) Wall and Window edit, move and delete functions/Tools.

2.) Global Setting tabs for Window and Door settings.

3.) Rudimentary Door and Window plugin that integrates with this plugin tightly.

4.) Wall Move and Split Tool.

5.) Add air gap parameter for the cladding (ie. brick fascia).

6.) Auto corner configuration

7.) Polyline Wall Tool and Face Wall Tool (right now all you can do is create a single segment at a time).

8.) Final clean and addition of any additional parameters to the Global Settings.

9.) Further refinements to the Add Window and Add Door Tools.

10.) Gable/Shed Wall Tool.

11.) Add glulam beams to Window and Door header options.

12.) Update Wall Plugin web page.I'm sure there are other items that are probably missing from this list but those seem to be the major items right now.

I probably should have just left them but the blocking and insulation algorithms were complex and so it took me a couple of days to figure them out and then commit them to code. At one point I just had to start over since my initial algorithm was too inefficient and the code quickly got out of control and became an ugly bowl of spaghetti for lack of a better word.

Please keep sending me your suggestions, they do not get lost. I am compiling another post-release "todo" list where all of these other items will be considered and hopefully the majority implemented.

-

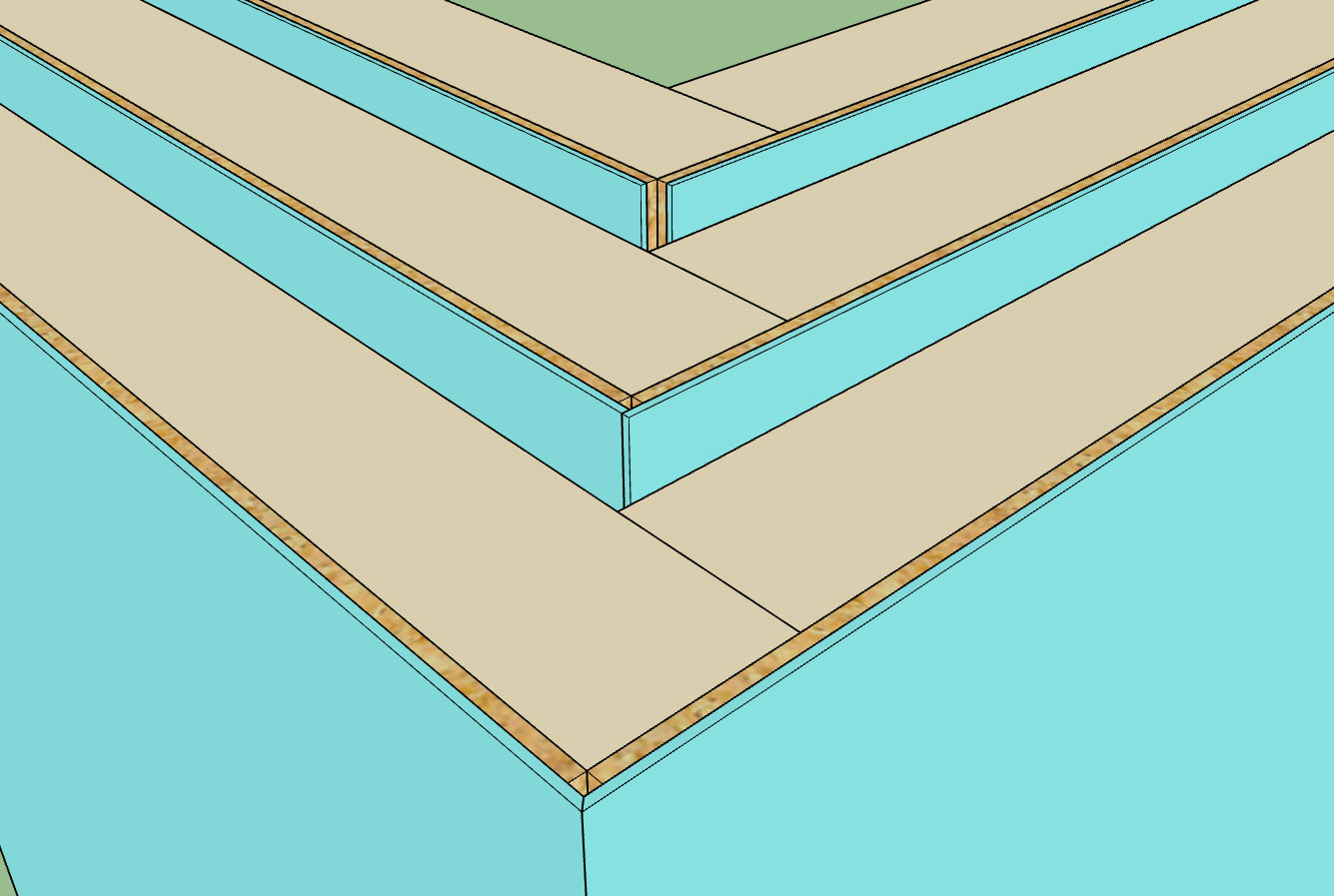

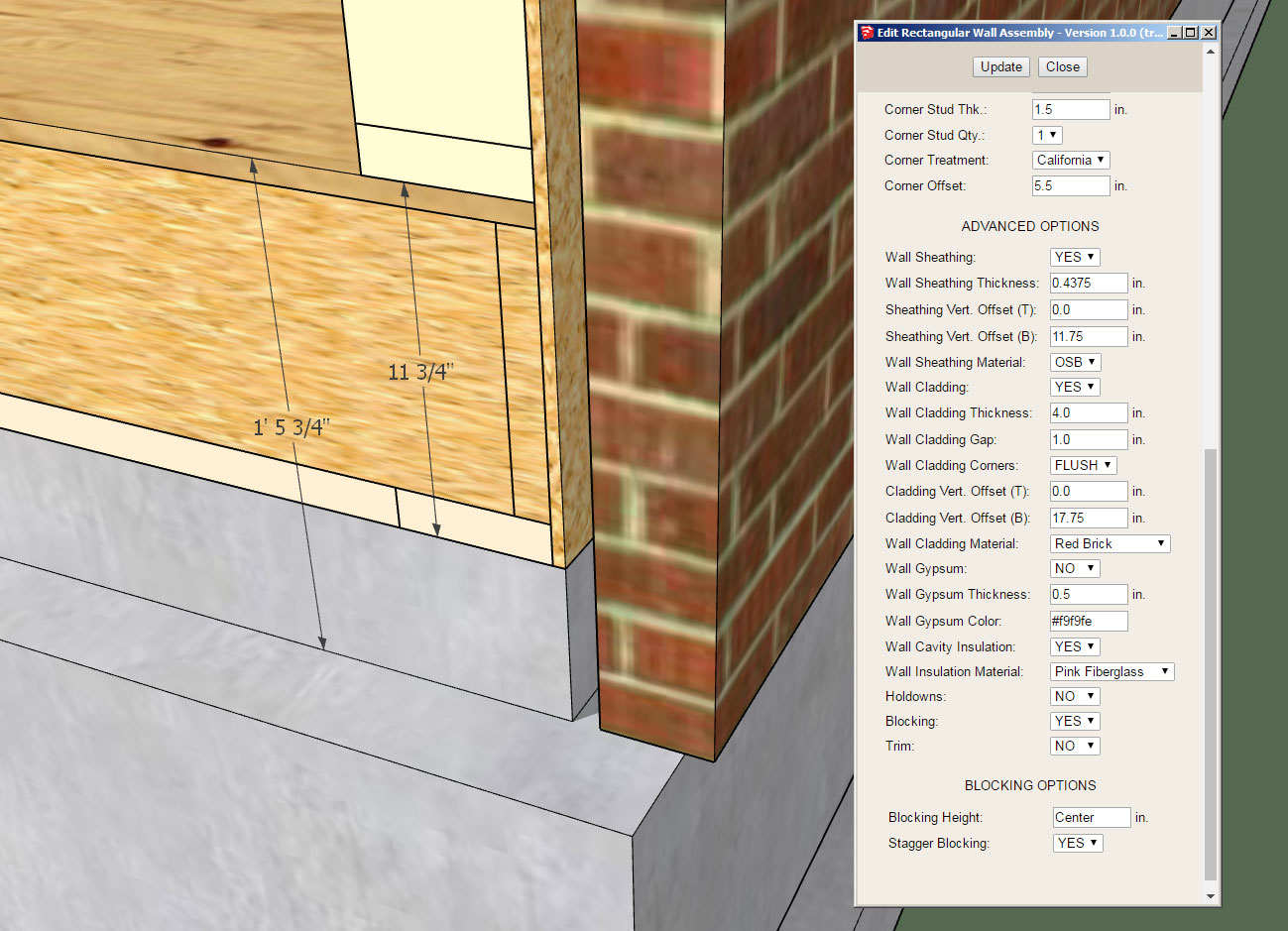

An additional parameter for cladding will added to the advanced wall options:

Cladding Corners: Flush/Lap/Miter

This parameter becomes important for certain cladding such as brick facade where the cladding thickness is significant and no corner trim will be present to cover up the corners.

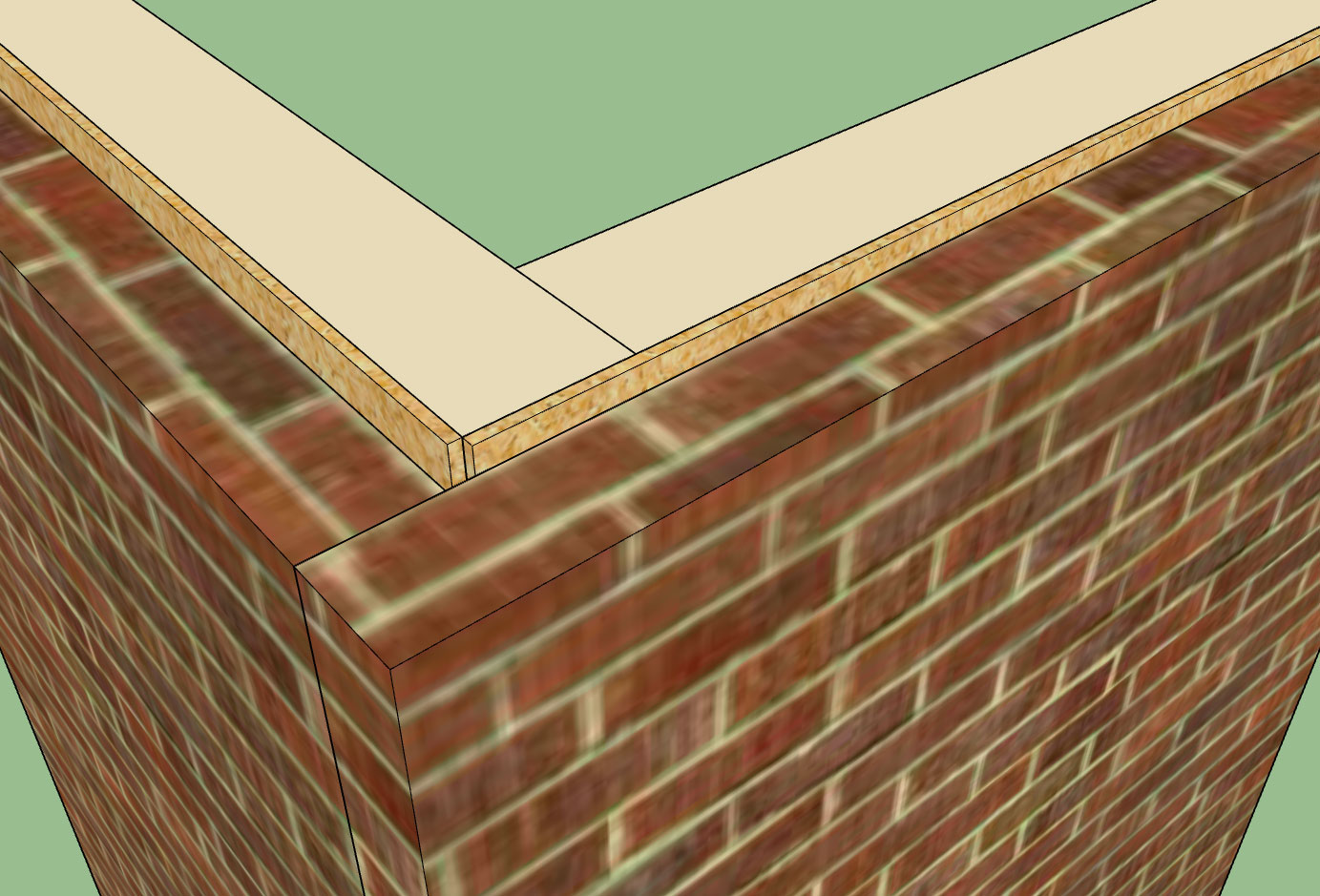

Another parameter that should also be added is an air gap, I am showing a 1" air gap between the brick cladding and sheathing in the image above.

-

I've added in the air gap and corner parameter:

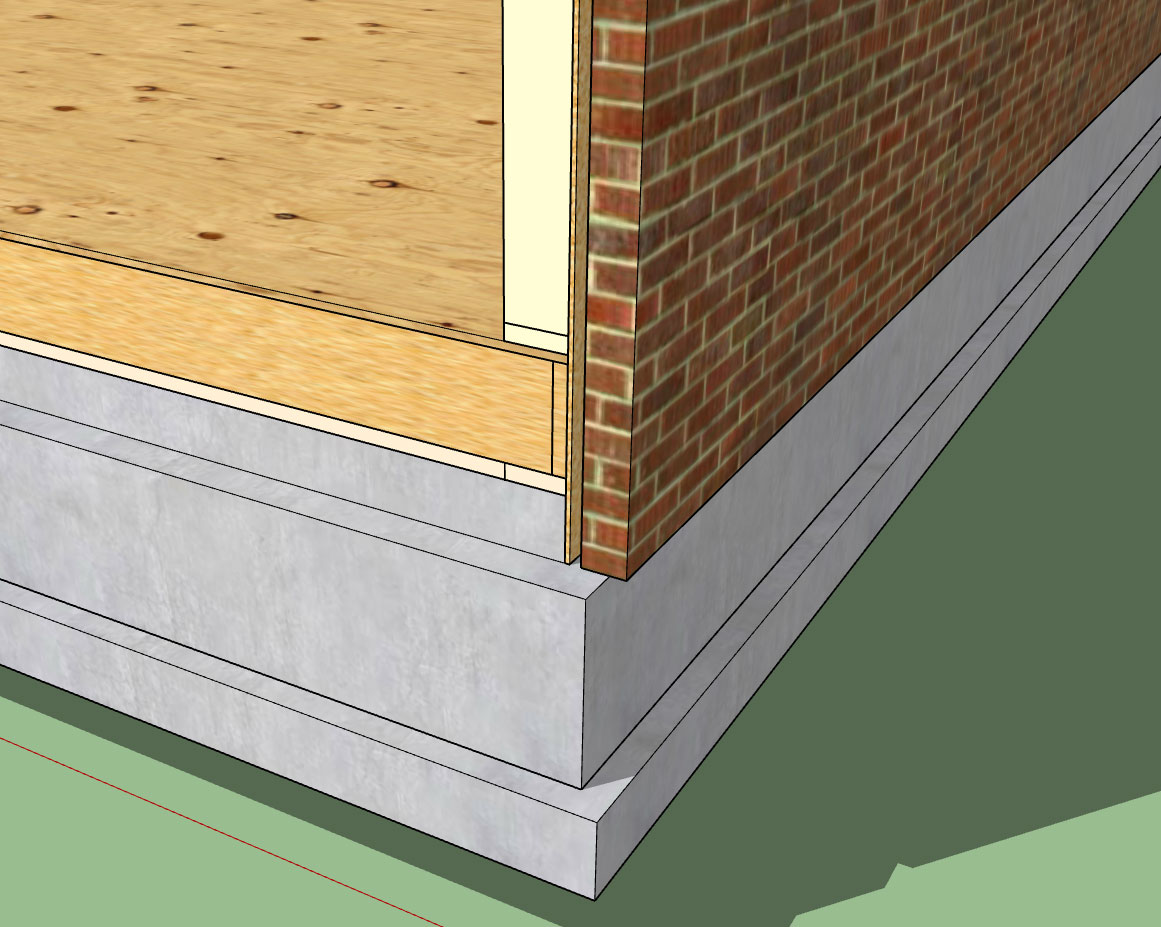

I then put a wall on top of floor and stemwall foundation:

The one thing that immediately jumps out at me is that the vertical offset parameter for the sheathing and cladding probably needs to be divided into two parameters so that the offset can be set separately for both sheathing and cladding.

-

I've separated the cladding and sheathing vertical offsets (top and bottom) into separate parameters so you can now offset each independently of each other:

Notice the two value in the edit wall menu for the offsets. This should allow for maximum flexibility, however the addition of more parameters might make the entire interface more overwhelming to some.

-

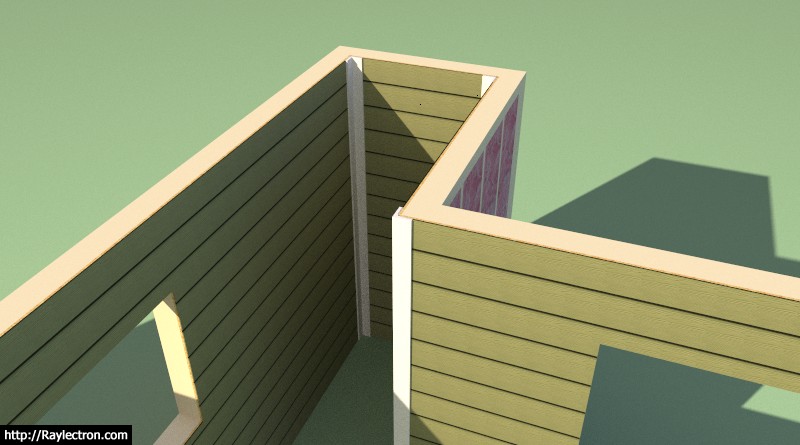

This evening I'm going to take a break from windows and doors and switch gears to the wall corner trim.

The wall corner trim (outside and inside corners) will be configured within the wall edit menu.

The door and window trim will be configured independently for each framed opening and edited within the door or window edit menu.

With trim in general I am trying to decide whether the trim should sit on top of the cladding or sit on top of the sheathing, or possibly a parameter that determines this location: ON SHEATHING/ON CLADDING

My initial list of parameters for the wall (corner) trim is looking like:

Trim Location: ON SHEATHING/ON CLADDING

Trim Thickness (in.): (defaults to 0.75 inches)

Outside Corner Trim: YES/NO

Outside Corner Trim Width (in.): (defaults to 3.5 inches)

Inside Corner Trim: YES/NO

Inside Corner Trim Width (in.): (defaults to 3.5 inches) -

You'll need to have both (on sheathing, on cladding) dependent upon what cladding you use.

-

@mtnarch said:

You'll need to have both (on sheathing, on cladding) dependent upon what cladding you use.

It makes more sense to put the trim on the the sheathing, since generally that is the way it is really constructed but there may be some designers who would like to have it on the cladding. I will provide the option for both.

In many cases the corner trim is assembled from two pieces but to start with I will go with the simpler monolithic corner piece (ie. AZEK).

-

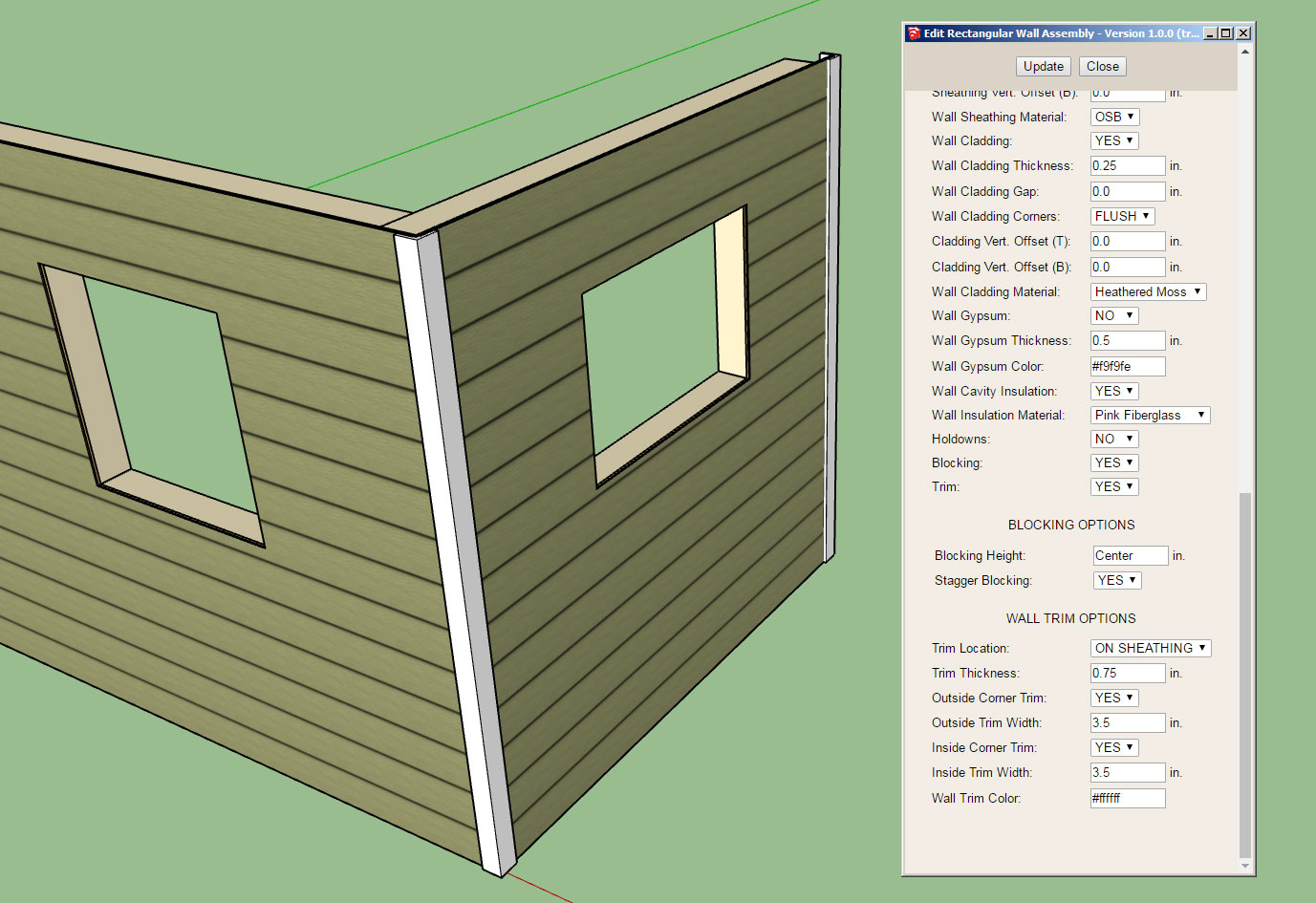

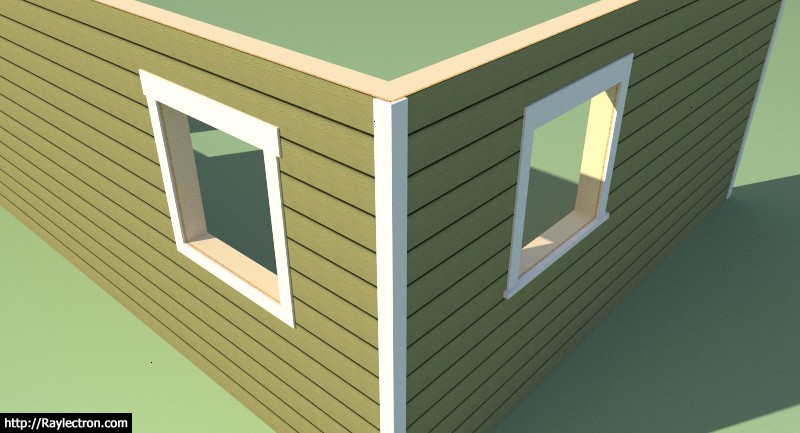

I've got the corner trim working reasonably well now:

It can also handle non-orthogonal corners.

-

That looks great!

-

The corner trim options within the Wall Edit Menu:

Then later today, a Style A (left wall) and Style B (right wall) window trim:

Style A is per the previous drawing I posted on the board. Style B is where the sill trim extends past the jamb trim(s). Note, that the thickness of the header, jambs and sill can all be independently set. At some point I would like to set it up so that users can save specific configurations

I'm now looking at the interior casing for the windows and also at the baseboard and crown molding trim. I'm not sure how elaborate I am going to get with this with the first go around, this may have to come later after the initial release. I'm trying not to get bogged down in the minutiae but as I've come to realize there are a lot of details when it comes to a full architectural design.

I'm also starting to think about the Windows and Doors. The doors (man doors) are fairly straightforward in my mind, use a typical pre-hung door, I've got some details that should guide me fairly well in that regard. Windows on the other hand are a real mixed bag, there are vinyl windows with the nailing flanges (the type I'm most familiar with) and then there are the much more expensive types. Any particular styles, brands or suggestions would be helpful.

-

Not sure this is in the plan, but of course it would make sense that a particular style is automatic for trim etc. once chosen. That is all new windows installed in the file come in with the correct style trim. Which leads me to the question with all parametric modeling like this where you seek to keep an identity for each object which can be updated: First, say you need to change all the trim at once--can you do that (happens to me all the time-- and components are helpful but don't do the whole job)? Secondly if the there is some window that must be different or there is something you must model "manually" which is outside the built-in options. What happens to those components down the road, can they somehow be integrated to the "smart" features of the model? A custom-modeled window that still has framing done by the plugin and cuts openings, is part of the materials list etc?

-

@pbacot said:

Not sure this is in the plan, but of course it would make sense that a particular style is automatic for trim etc. once chosen. That is all new windows installed in the file come in with the correct style trim. Which leads me to the question with all parametric modeling like this where you seek to keep an identity for each object which can be updated: First, say you need to change all the trim at once--can you do that (happens to me all the time-- and components are helpful but don't do the whole job)? Secondly if the there is some window that must be different or there is something you must model "manually" which is outside the built-in options. What happens to those components down the road, can they somehow be integrated to the "smart" features of the model? A custom-modeled window that still has framing done by the plugin and cuts openings, is part of the materials list etc?

A little bit to digest here, I will think on it. This project has ballooned well past my original estimate of what it would be. Like the truss plugin, I'm sure I'll be adding features and functionality well into the foreseeable future.

-

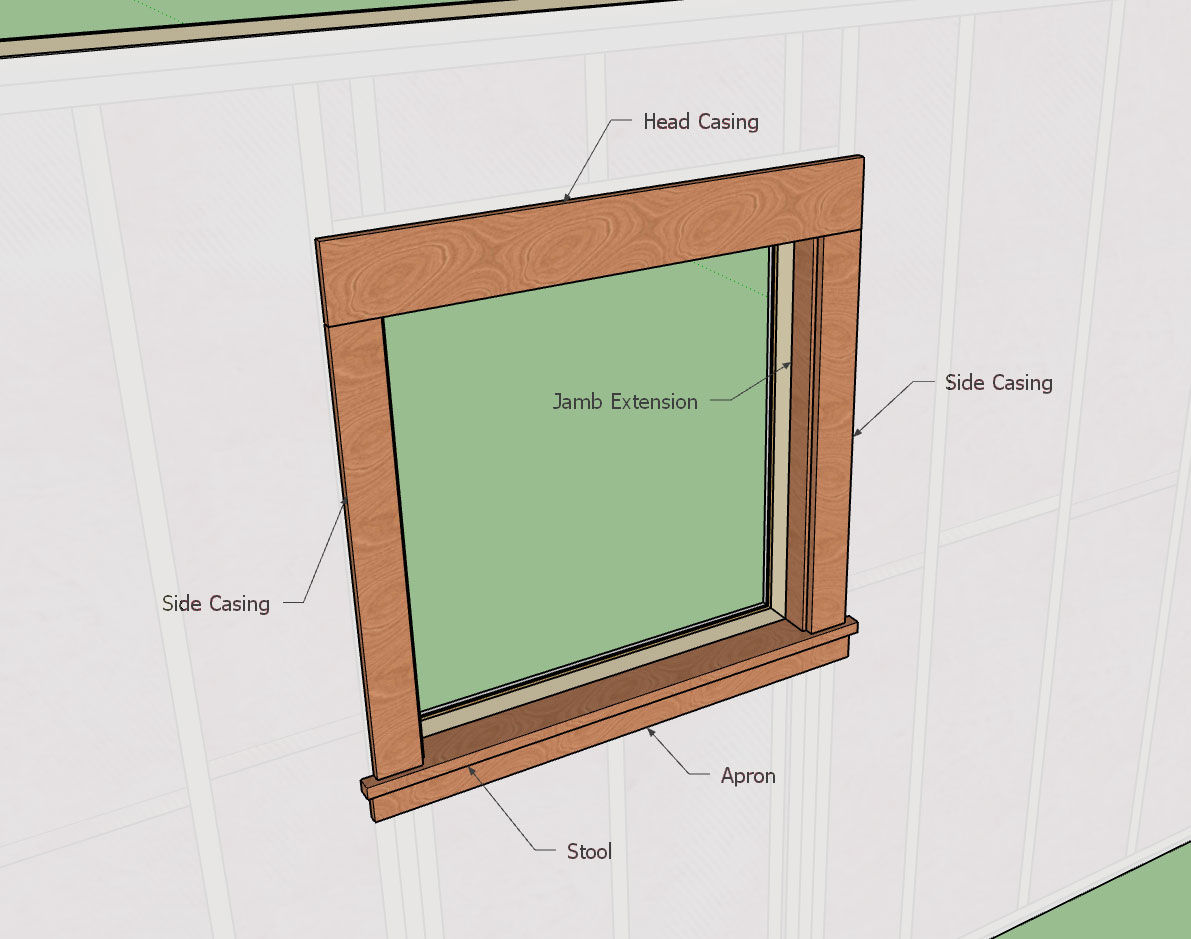

Here is my draft for Window Casing (Style A):

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

The parameters will probably be:

Head Casing Width: 5.5"

Side Casing Width: 3.5"

Apron Width: 2.5"

Jamb Ext. Depth: 2.5"

Casing Thickness: 0.75"

Stool Thickness: 1.0"

Apron Thickness: 0.75"

Jamb Ext. Thickness: 0.75"

Header Extension: 0.0"

Stool Extension: 1.0"

Apron Extension: 0.5"

Stool Projection: 1.25"

Casing Reveal: 0.25"

Shim Gap: 0.25"The values given are the default values and coincide with the model given above.

Some details show shims between the framing and the jamb extensions, others do not:

-

@pbacot said:

Not sure this is in the plan, but of course it would make sense that a particular style is automatic for trim etc. once chosen. That is all new windows installed in the file come in with the correct style trim. Which leads me to the question with all parametric modeling like this where you seek to keep an identity for each object which can be updated: First, say you need to change all the trim at once--can you do that (happens to me all the time-- and components are helpful but don't do the whole job)? Secondly if the there is some window that must be different or there is something you must model "manually" which is outside the built-in options. What happens to those components down the road, can they somehow be integrated to the "smart" features of the model? A custom-modeled window that still has framing done by the plugin and cuts openings, is part of the materials list etc?

I've been thinking about this some more and this is the reason I created the Wall Grouping parameter. I haven't fully fleshed this one out yet but the idea is that if you have a bunch of wall panels that belong to the same group (not a SketchUp Group) then when you edit certain parameters such as wall height all of those wall panels will be updated to reflect that change to anyone of the wall panels within the group. Certain parameters, of course, should be exempt from this "group action". What I would like to do is have a tab within the global settings where you can specify which wall/window/door parameters will be affected by the group editing feature.

So for instance if you enable Window Trim as parameter(s) that will be affected by wall groups then when you edit the trim of one of the wall panels within the group the trim for every window within that grouping will be updated to reflect that change.

Currently any manual edits to the wall panel and all that resides within its SketchUp group will be blown away as soon as any edit is done with the plugin. The way to avoid this is to put any geometry outside of the wall panel group. That geometry will then been unaffected by anything the plugin does. There may be a way to set this up so that manual edits are somehow stored or accounted for but I haven't figured that out yet.

When you really analyze how the plugin works it is little more than a database (attribute dictionaries) which then converts that information into SketchUp geometry. The wall panel, its openings and all other characteristics and settings are fully defined within these dictionaries and that is how I am able to create a system where you can change parameters and "edit" a wall panel. When you edit a wall panel it is creating the entire wall panel from scratch just from the attributes stored in the dictionaries.

-

Thanks for the information! That makes sense. Maybe there'll be some way to incorporate custom work, sort of "bless" it to be accommodated and preserved within the wall group, but the great about your plugins is to get all the standardized systems of construction into the model fast with a lot of flexibility built in.

-

Here is a quick preview of the Window Trim and Interior Casing:

In this video I'm only showing Style A of the interior casing, I will finish up Style B later tonight.

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

Window Casing Options:

From right to left:

- No Casing

- Style A: Full Casing

- Style B: Stool and Apron with Gypsum jamb and header extensions

- Style

Full Gypsum jamb, sill and header extensions

Full Gypsum jamb, sill and header extensions

Advertisement