A locking tenon joint?

-

I like that hexagon biscuit and your model though! Seems that joint is taking on a lot. I'd love to see what joint would work best there.

-

I would do it that way.

Robert

-

Good thoughts, pbacot.

Bob, I think you almost nailed it, so to speak.

It hadn't occurred to me to make one member in the joint a different shape from the others. I'd convert your tenon to a dovetail, however. That shape will definitely lock the two halves of the joint together.

Best,

dh -

Cool table David

. I think I've seen a drawing of the Japanese joint your referring to, but it's been so long I can't remember the exact details. Was inspired to put my own spin on it by everyones posts.

. I think I've seen a drawing of the Japanese joint your referring to, but it's been so long I can't remember the exact details. Was inspired to put my own spin on it by everyones posts.

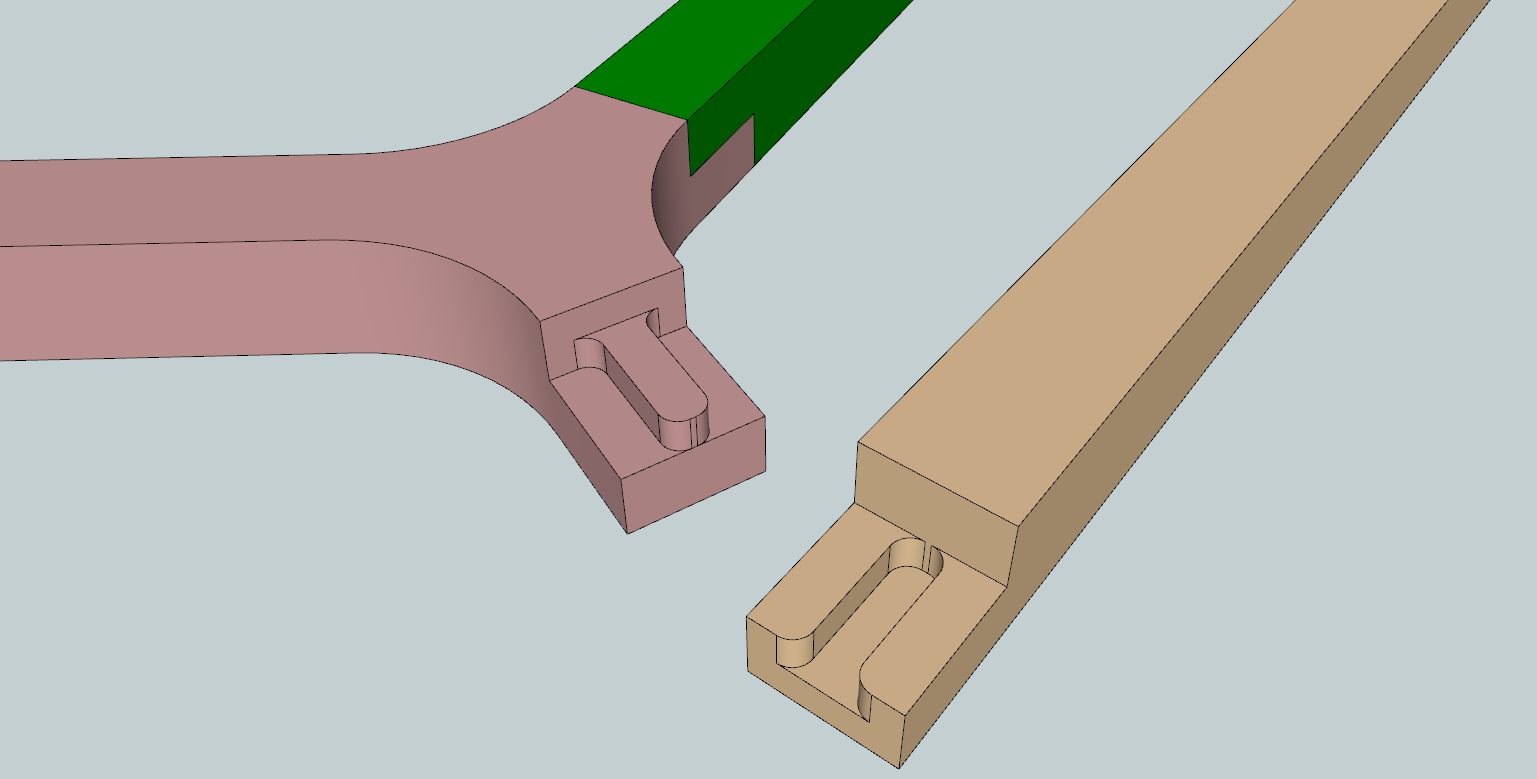

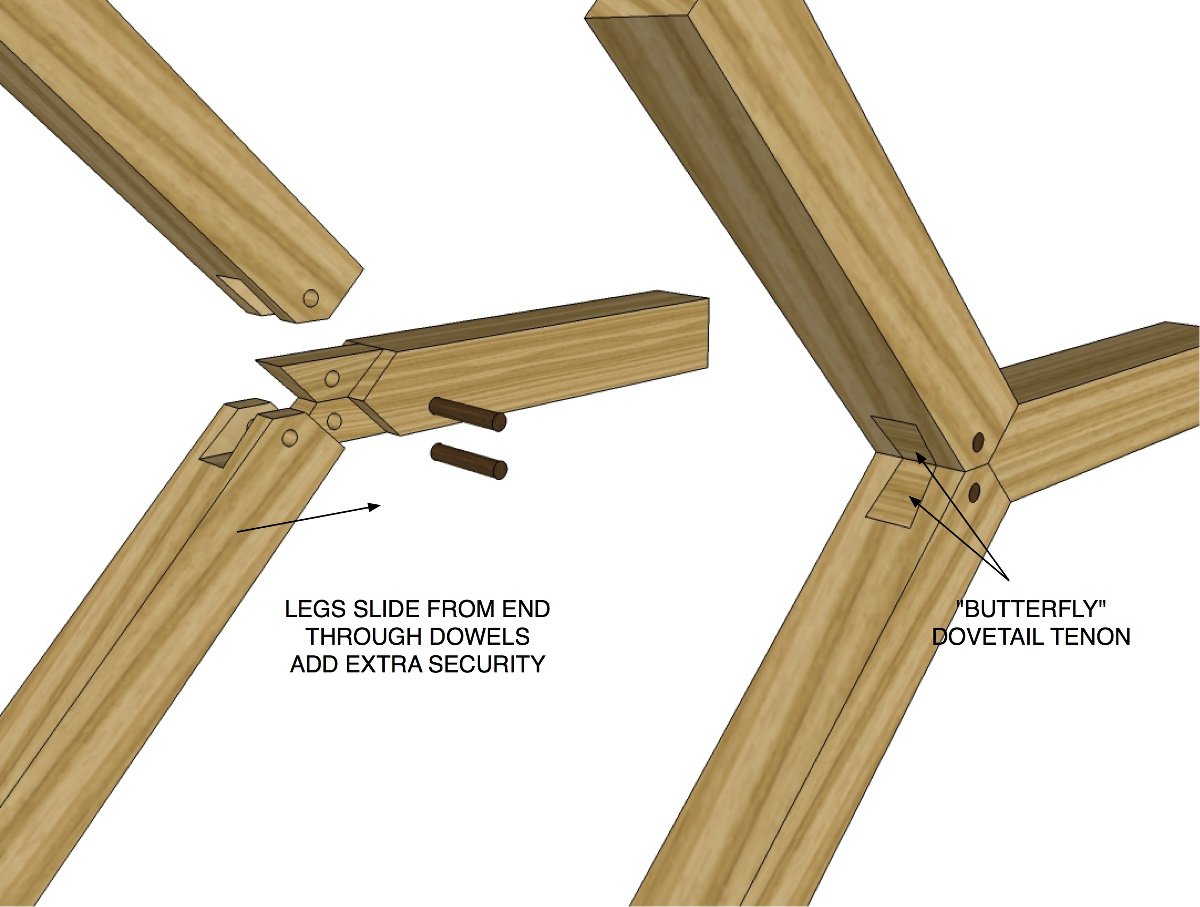

The stretcher has the tenon that"s cut like a butterfly dovetail. If that makes sense, narrow in the center tapers out at top and bottom. Corresponding mortises cut into leg pieces that slide straight in from the ends. I'd pin them with through dowels for a little extra holding power.

You have my curiosity up. I'll have to dig into my old reference material for the Japanese joint.

-

Excellent joint, tuna--especially working from memory. I think if you shaped the tenon like a double-dovetail, you wouldn't need the extra pins.

Many thanks.

Best,

dh -

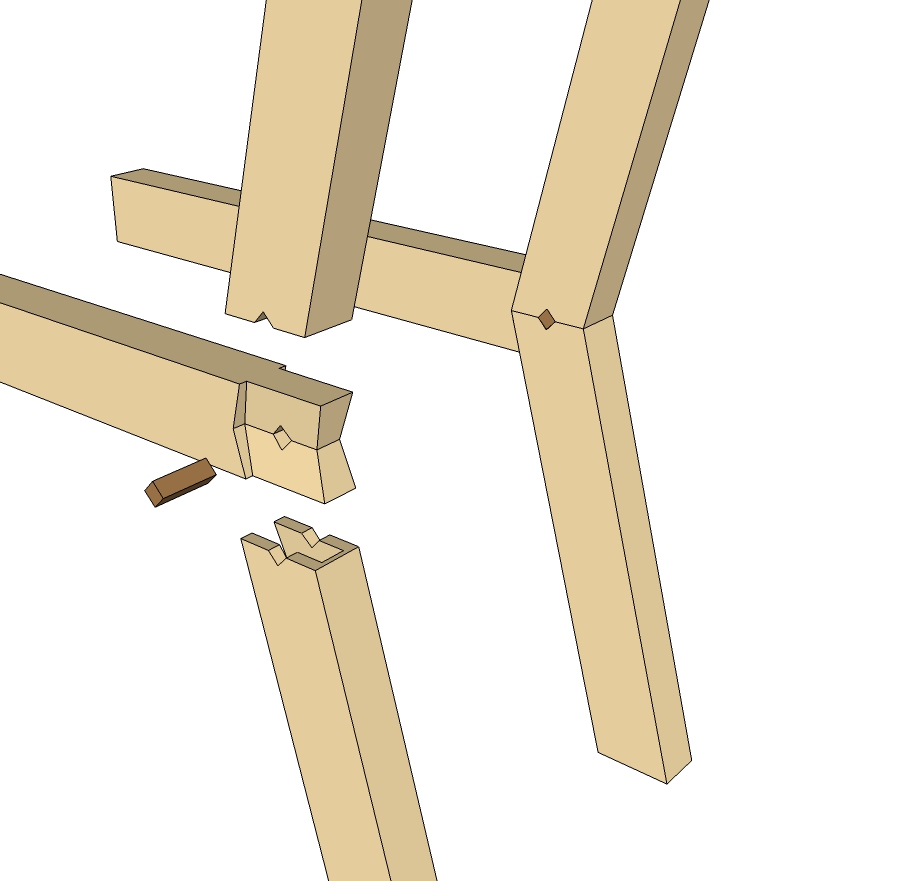

How does this look? It's a variation of tuna's joint.

Best,

dh -

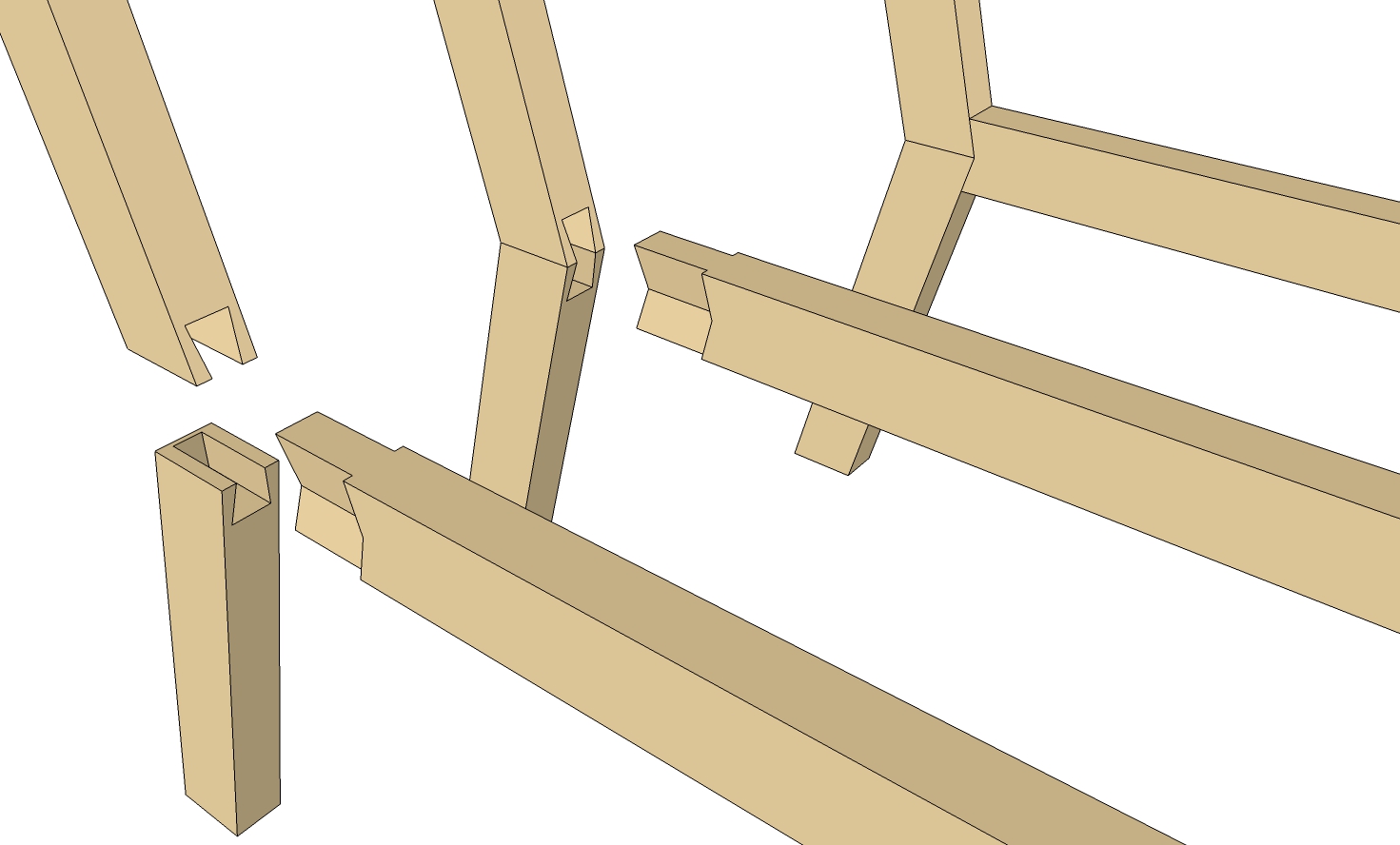

David, This rattled in the back of my melon head all day. Think I got it figured out

.

.The tenon end is hidden when assembled. Should only require glue for a strong joint. Each leg piece slips onto the dovetailed tenon. The angle cheek cuts on the stretcher should resist sagging of the leg pieces. Better be damn handy with a chisel if your going to make this joint. Cheers, tuna.

-

You nailed it, tuna!

Nice work.

Best,

dh -

Thanks David. Couldn't help making one more minor variation to the joint. Added a square dowel through the joint. It is centered on the midline of the tenon. Driven in after the parts are assembled the joints not coming apart even if the glue fails. This kind of locking peg is pretty common in large scale Japanese joinery. I'm not sure if it's common in furniture construction.

-

Nice touch, tuna.

Got me thinking . . . .

If you use a drawbore pin in each half of the joint, you might not even need glue. (The hole in the piece with the dovetail socket would be offset about 1/64" from the hole in the dovetailed tenon. Forcing the pin into the hole draws the two parts of the joint together.)

Best,

dh -

David , Your correct about draw boring for the peg. Offset hole in tenon, peg a little longer than needed , taper one end real good and there you have it. I'm sure most of the pegged joints the Japanese craftsmen cut for timber framing were draw bore. Still don't think my saw and chisel skills are good enough for this kind of work....

-

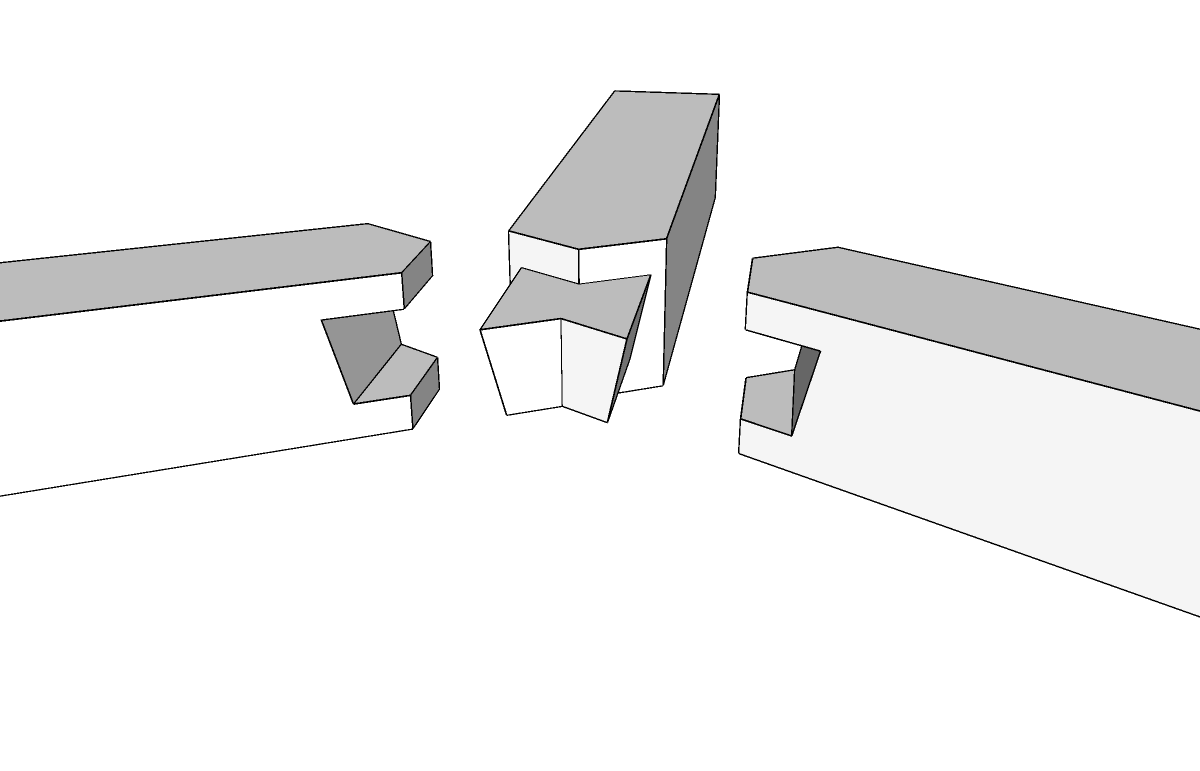

I'm certain my geometry is off as to rake angle's/etc.......that said; I had a go at it just for fun as to what the "lock tenon" might look like.

-

An elegant alternative, Charlie. If there's a way to shape the tenon like a butterfly key, then you'd have a real locking joint.

Thanks for taking the time to work through this.

Best,

dh -

@davidheim1 said:

An elegant alternative, Charlie. If there's a way to shape the tenon like a butterfly key, then you'd have a real locking joint.

Thanks for taking the time to work through this.

Best,

dhThanks dh

I started to wonder if the "lock" in lock tenon was maybe taken a bit too literal?

So I made a second attempt with that in mind...... IDK....maybe the upper & lower part of leg get "rotated" to fit together and then slipped over tenon? (just a carpenter here, and not a master woodworker)

IDK....maybe the upper & lower part of leg get "rotated" to fit together and then slipped over tenon? (just a carpenter here, and not a master woodworker)C

-

Very colorful and ingenious. Thanks for taking the time to model this. But it doesn't look as if the tenons on the brown part can be fitted into the mortises in the purple and green parts. The tenon fitting into the purple part works, but I don't see a way to get the tenon into the mortise in the green part. The long tenon on the purple part will prevent the other pieces from rotating into position. But if you make the purple tenon butterfly-shaped, then I think you'll be on to something.

-

@davidheim1 said:

Very colorful and ingenious. Thanks for taking the time to model this. But it doesn't look as if the tenons on the brown part can be fitted into the mortises in the purple and green parts. The tenon fitting into the purple part works, but I don't see a way to get the tenon into the mortise in the green part. The long tenon on the purple part will prevent the other pieces from rotating into position. But if you make the purple tenon butterfly-shaped, then I think you'll be on to something.

Dh

I was thinking the brown and green get assembled as a unit first. (Rotating both so tenons could “fit” together)

Then, brown and green assembly slips over the purple parts (long)tenon and lastly brown/green smaller tenons engage purple part.I’ll see if my Fredo Animator plug in still works and try to post a video of assembly.

If not, ill just put a few scenes together to demonstrate what may be lacking in my verbal assembly description.And yes, butterfly shape on purple long tenon would definitely make is a true locking tenon.....just don’t Know how that is possible in this configuration.

C

EDIT: UPLOADED .gif

-

Charlie,

Now I get it. Your locking joint works just fine. Thanks for the gif.

Best,

dh -

To force the final [purple?] tenon to lock firmly into the mortise...

Make it with a central small tapering horizontal cut along its length, make it widest at the visible end.

Make the tenon-mortise's cross-section so that its external end is slightly bigger that its start size.

After the joint whole is assembled, you can then drive a glued wedge into the tenon's exposed cut.

Over size the wedge's length so that after its firmly in and all is set, you can trim off the excess exposed end of that wedge and finish everything neatly.Now all of these connections are locked in all directions ?

-

@tig said:

To force the final [purple?] tenon to lock firmly into the mortise...

Make it with a central small tapering horizontal cut along its length, make it widest at the visible end.

Make the tenon-mortise's cross-section so that its external end is slightly bigger that its start size.

After the joint whole is assembled, you can then drive a glued wedge into the tenon's exposed cut.

Over size the wedge's length so that after its firmly in and all is set, you can trim off the excess exposed end of that wedge and finish everything neatly.Now all of these connections are locked in all directions ?

TIG,

Thanks....& Aha....much like an Axe handle wedge, to keep the axe head from flying off.And also goes to dh's thinking on butterfly joint as final "lock".

I only tapered the tenon's mortise 1° which actually seems like a bit too much? (maybe not)

Please see GIF

____________________________________________________________________________________________________

EDIT: I should have properly thanked Fredo for his Animator plug-in used to create the GIF’s in this thread ......so Thank you Fredo, for all the magic you have done with the Animator plug-in!

____________________________________________________________________________________________________

-

I think that does it. Thanks to TIG for suggesting the wedged tenon and to Charlie for producing yet another version of the joint.

Best,

dh

Advertisement