Curviloft Thickness

-

So I was playing around with Curviloft, and I was wondering: Is it possible to give your loft a thickness? Even if you select a face to follow the path, only the edges are extruded. It would be great if it functioned like "Follow Me," where you get a thickness. Other than that, Curviloft seems incredibly useful.

-

You could use Fredo's Joint Push/Pull to create the thickness.

-

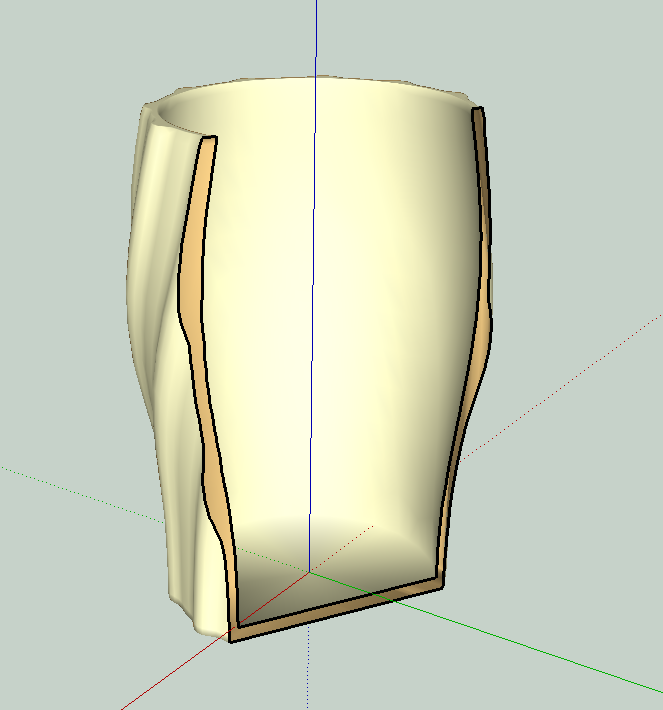

Interesting tool that I will probably use elsewhere, but it seems like even a slight twist in a loft (made with Curviloft) gives joint push pull trouble. I guess that's just from the surfaces Curviloft built. I'm new to Sketchup and thought it would be fun to print vases with Curviloft. Any suggestions for issues like the one in the attached picture?

-

What Dave said, have used joint push pull to get thickness to small boat hulls after creating the shell with curviloft. Works great.

-

Just do it twice on the same curve.

-

@reb629 said:

Interesting tool that I will probably use elsewhere, but it seems like even a slight twist in a loft (made with Curviloft) gives joint push pull trouble. I guess that's just from the surfaces Curviloft built. I'm new to Sketchup and thought it would be fun to print vases with Curviloft. Any suggestions for issues like the one in the attached picture?

[attachment=0:47fudnk0]<!-- ia0 -->JointPushPull_5DegreeTwist.PNG<!-- ia0 -->[/attachment:47fudnk0]Could you share the starting point before you run Curviloft? and what are you hoping to wind up with?

-

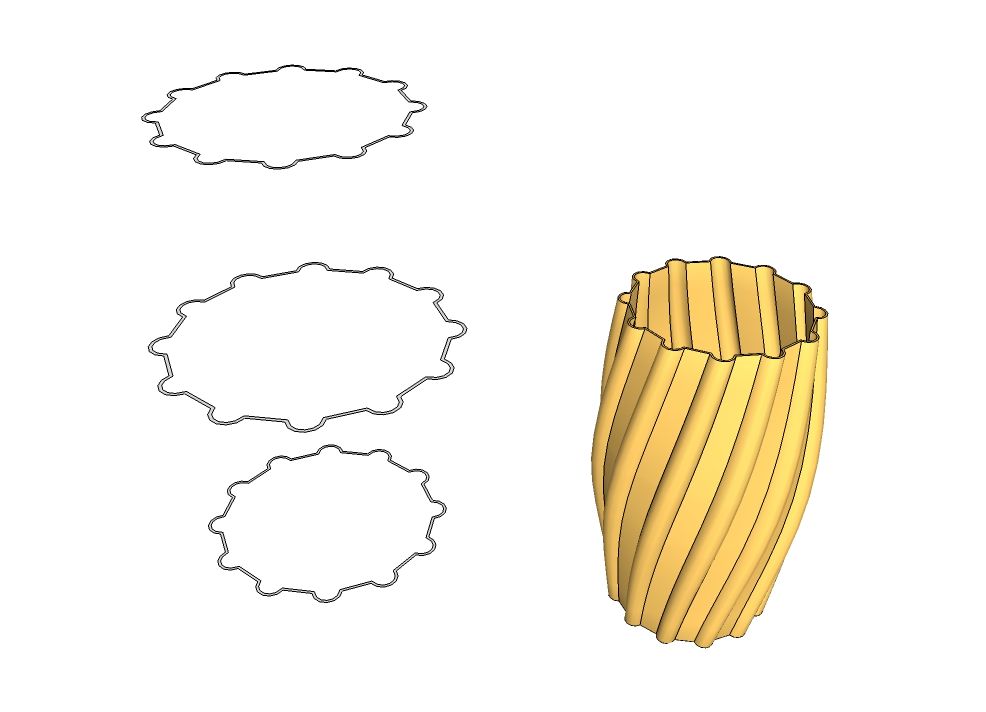

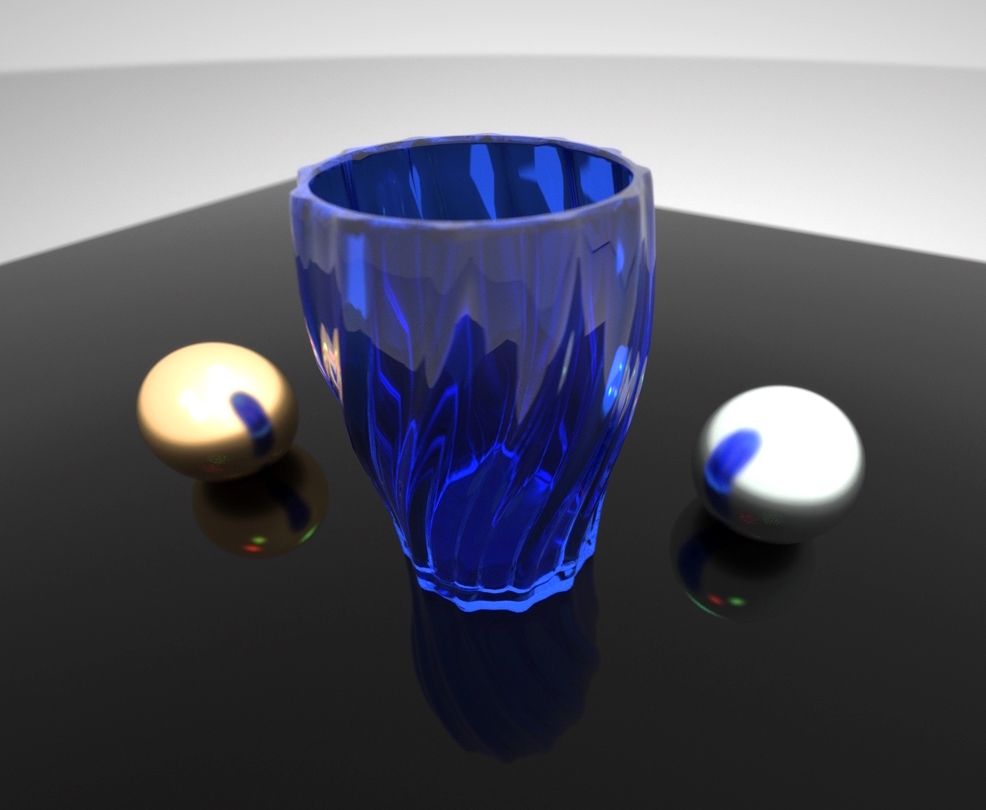

The original profile can be seen below.

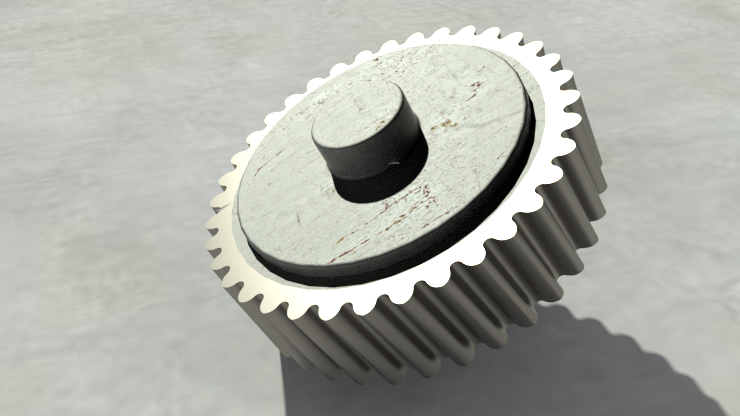

I put the same profile a couple inches higher, rotated it 5 degrees, and lofted between the surfaces using Curviloft. I was trying to replicate something like this twisted gear vase. I'm open to any other suggestions for how to approach it. Thanks for the help.

-

@reb629 said:

Interesting tool that I will probably use elsewhere, but it seems like even a slight twist in a loft (made with Curviloft) gives joint push pull trouble. I guess that's just from the surfaces Curviloft built. I'm new to Sketchup and thought it would be fun to print vases with Curviloft. Any suggestions for issues like the one in the attached picture?

[attachment=1:bldmc5gc]<!-- ia1 -->JointPushPull_5DegreeTwist.PNG<!-- ia1 -->[/attachment:bldmc5gc]No need for curviloft, just make gear tooth pattern, push-pull and rotate (twist) bottom edge 5 degrees.

Of course, there are gear-making plug-ins

[attachment=0:bldmc5gc]<!-- ia0 -->Gear.png<!-- ia0 -->[/attachment:bldmc5gc]

-

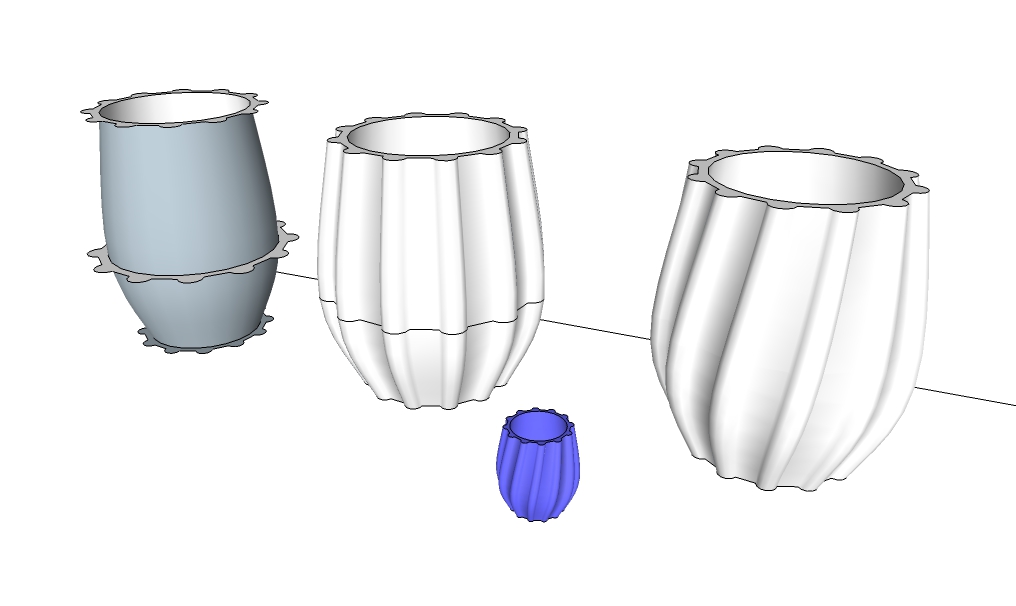

Now that I understand just what your trying to do here's a way to get there. The steps you do are from left to right in the picture.

Draw your "sprocket". Make a hole in the center for the inside wall. Make it a group. Copy the sprocket up, I did it twice. Scale the sprockets to give the vase taper.

Use Curviloft - Loft by Spline and select the inside edges of the sprockets to get the inside of the vase. Do the same selecting the outside edge of the sprockets for the outside of the vase.

Use Joint Push Pull to give the bottom of the pot thickness.

Use Fredo Scale Box Twisting to twist the vase. Twisted the sample 20 degrees.

One tip , Work BIG, the model is 4' tall, then scale down. Colored vase in front is a more realistic 12" tall.

-

The Fredo box twist is a great tool - thanks for the detailed help! I successfully made a vase, but I'm still curious if anyone has advice on adding thickness to complicated surfaces like the outside of this vase. I get geometry errors when I use Joint or Round Push Pull (works fine on the simpler inner surface of the vase). In order to print this, won't it need to have a thickness instead of being a lofted curve? (I'm not new to CAD, but I'm new to Sketchup and 3D printing. Thanks for the help.)I guess there's probably a way to fill in between the inner and outer lofts - that would maybe be easier, but use more material.

-

It looks like you have thickness??? Is it a "solid"/ manifold?

-

It looks like that because I left the face used for Curviloft up there, but Curviloft doesn't loft faces, only curves. So if I delete that top face, you can see that the vase is just extruded curves. I did give the inner surface thickness.

-

You're producing a great deal of new faces and likely some of them will to small for SketchUp to form. Try working at a scale of 100x or 1000x and see if that helps.

-

Not sure why your trying to make your model like this. I'm no expert at 3D printing but have been researching and reading up on it of late. As I understand the process on an object like a vase the thickness of the print would be the distance between the inner and outer wall of the model. It just seems that would be the logical way to make an object like a vase so it's walls are solid. Seems like your trying to model it so there would be a hollow cavity between the inner and outer wall ? If it's trying to cut down the amount of material used I've posted a pick of another vase. The inside follows the contour of the outside. It's actual thickness would be determined by the requirements of the printing material used. As a side note both models I posted check out as solid and could be printed.

If your determined to keep trying what you've been doing. Try using JointPushPull on the outer surface before you twist the vase. After the twist the geometry is insane and it's asking a lot of JPP to try and pull thickness on something with that crazy of geometry. If JPP works before the twist you could group everything and then give it the twist. Remember work REAL BIG !

One last thing if you haven't already, you might talk to a 3D printing service for the best way to approach this.

Oh and if your wondering I scaled the vase down before I saved the image. Sprockets are at the size I did all the modeling.

-

Yep, I realized I should be using Joint Push/Pull BEFORE twisting and I felt pretty dumb. Whoops.

I agree that I'd rather have the thickness of the vase just be the distance between the inner and outer walls. The reason I was having trouble is Curviloft only lofts curves, not faces, so I moved on to thickening the vase walls instead. Maybe my knowledge gap is with building the stl model. If I have a gap between the inner and outer surfaces, is that okay when I move on to the stl phase? Or I can make a solid using the vase walls in a later step?

-

I am having a very hard time getting a solid out of my curves/vase. I decided to investigate my base profile more....When I pull each of the faces created by my sprocket profile, for some reason the inner circle is just moving...instead of creating a solid cylinder. Does anyone know why this might be?

-

That seems right. If you intend to leave a face where it started,you press the Control key(?)in windows. On the Mac I press the option key, and I looked for this in "knowledge center" and it's buried somewhere, so try one of those windows keys...

-

Here is a vase sort of like yours. I made it with plugins you probably don't have. But the point is, even with curviloft you get the inner and outer surfaces, and you need to complete the top and bottom. I don't do printing but I think this would print because when grouped SU says it is "solid". It just has the surfaces continuous with no holes and no extra faces or edges.

Made this with push pull (and duplicated the base curves several times), Vertex tools, and Artisan (to smooth it).

-

Okay, so I guess the reason my vase is not a solid must be due to the curviloft then? If I push/pull the base profile and then run SolidInspector, I have to fix some reversed faces and internal faces (no hole in face like with curviloft below), but then I do get a solid. If I run Curviloft and then Solid Inspector though, I get the following errors. The hole in the face is Solid Inspector thinking the top of the vase should be covered like a jar...:

I attached my sketchup file in case anyone is interested.

-

Advertisement