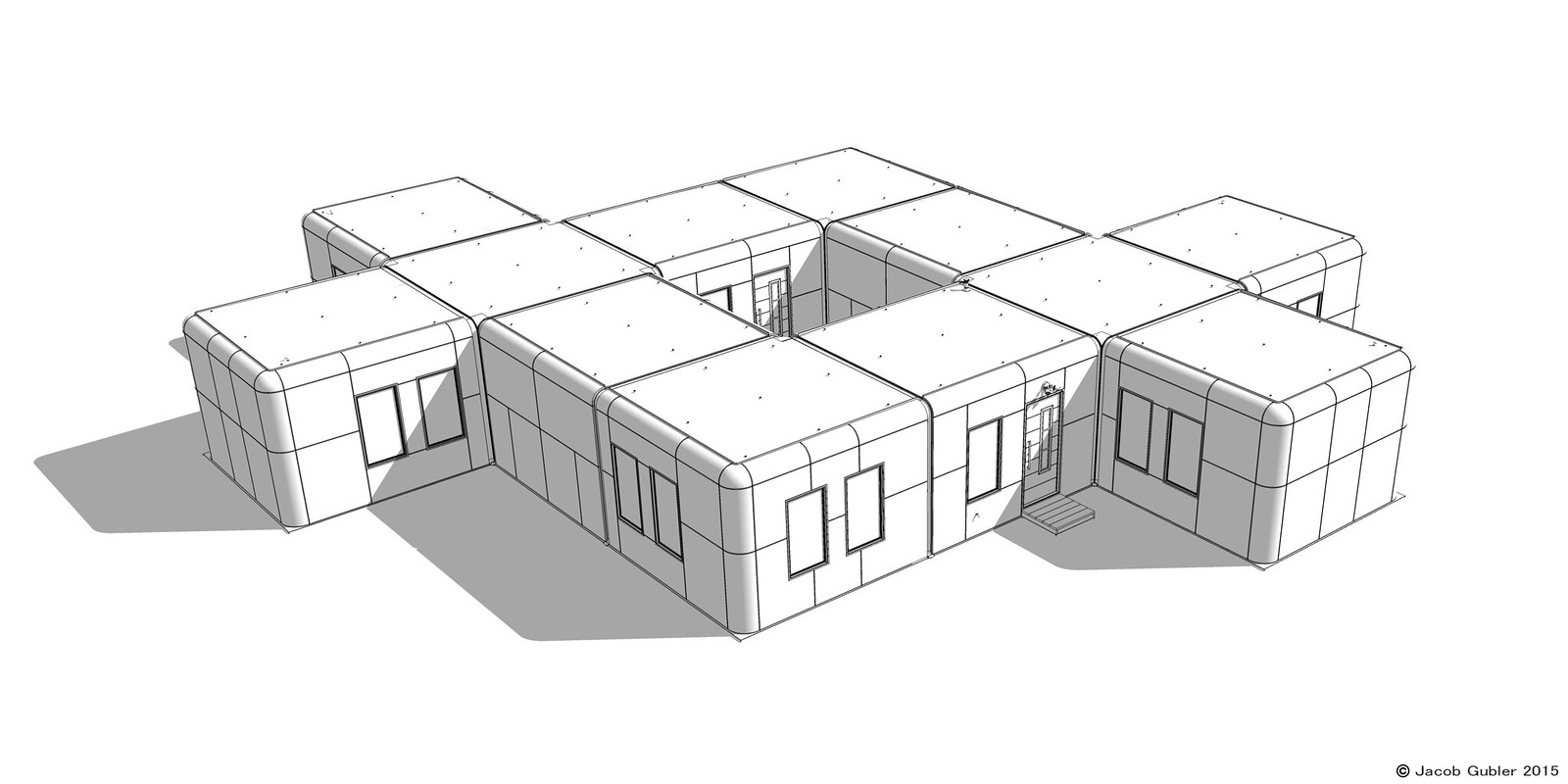

GoMicro - Prefabricated Modular Microhome Concept

-

Questions, comments, criticisms welcomed.

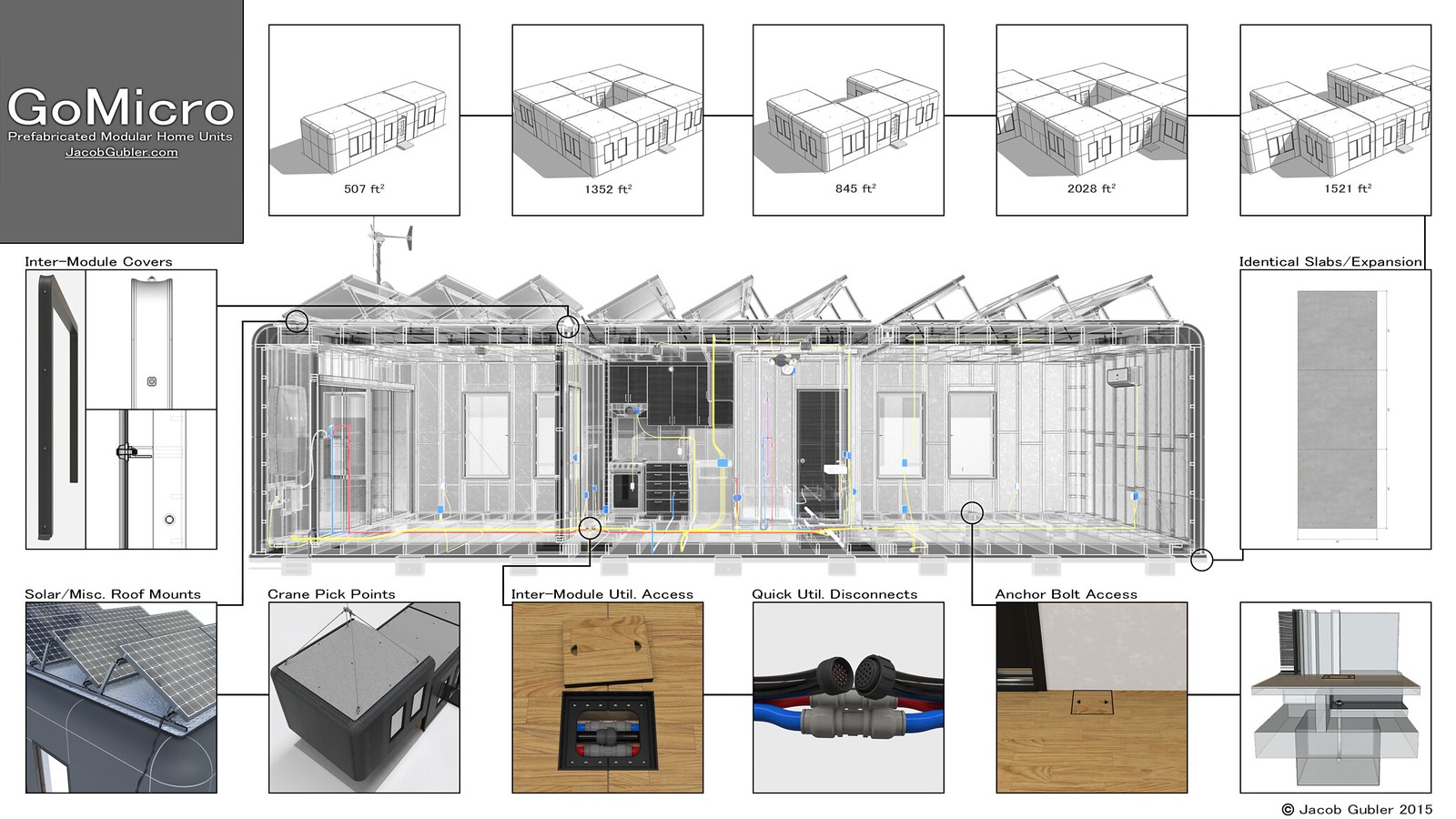

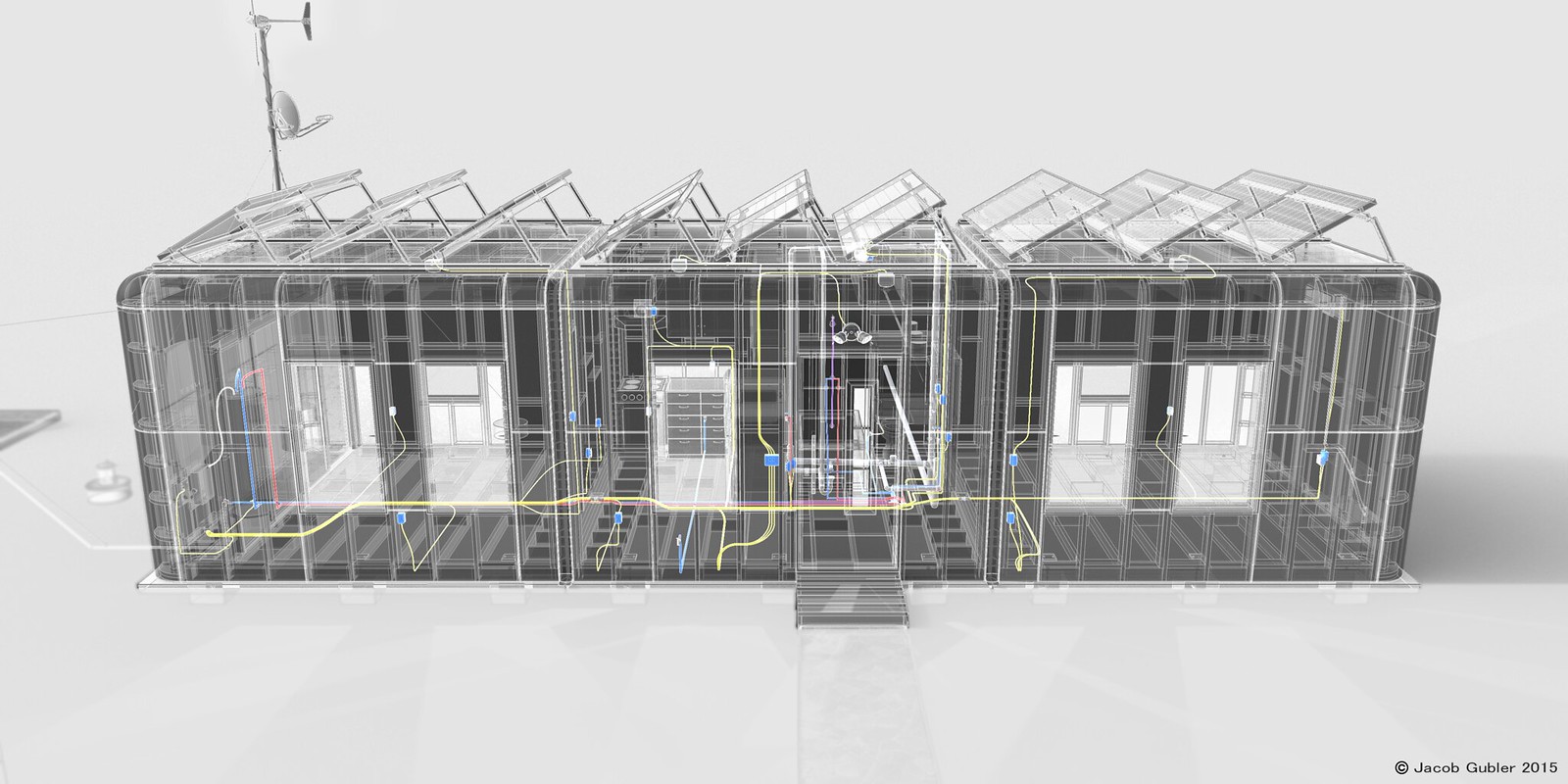

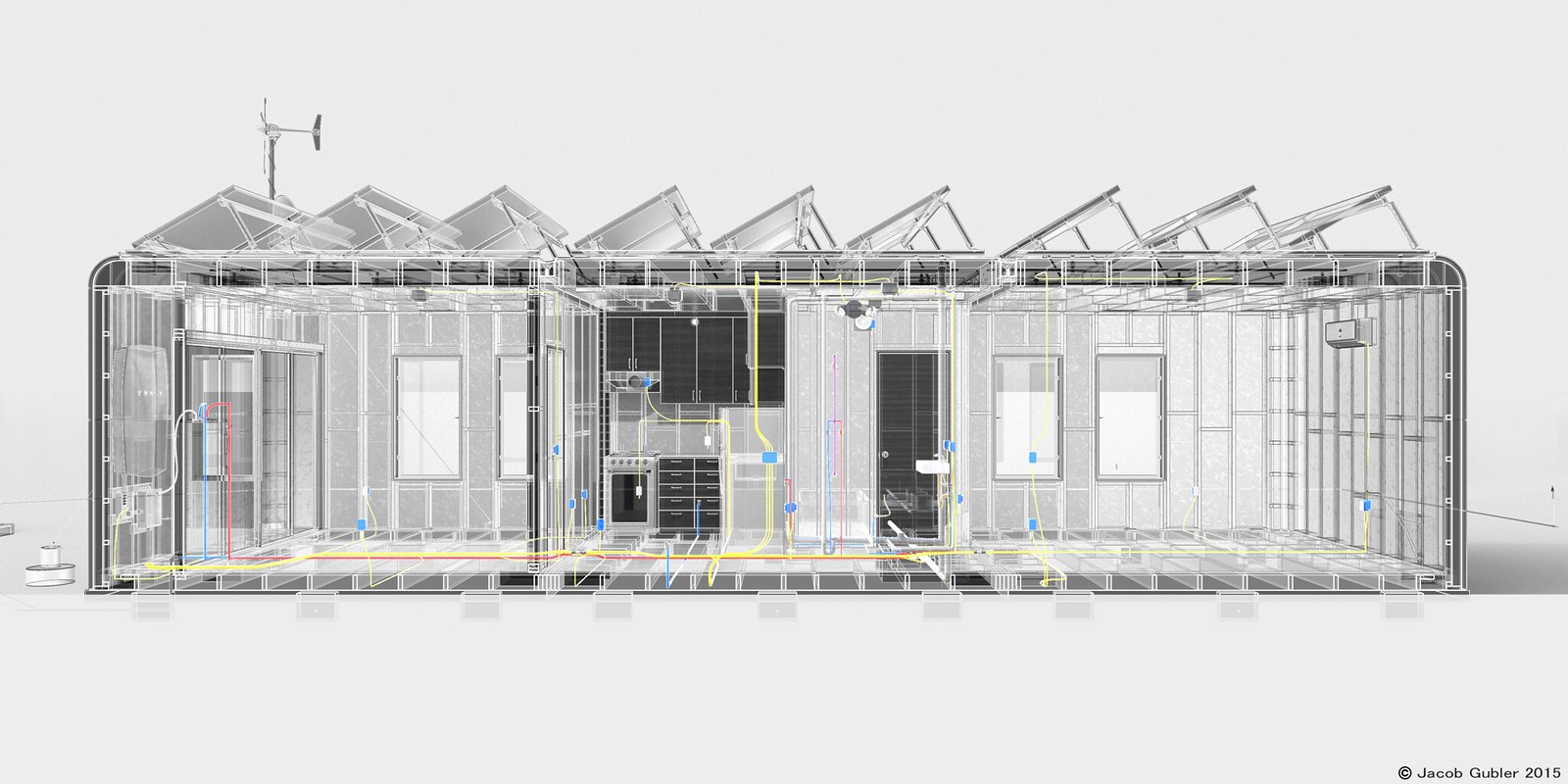

GoMicro is an environmentally friendly, affordable and expandable form of housing. A prefabricated, modular system built to 95% completion and delivered, reducing site work requirements to a minimum. Semi-permanent, the module assemblies can be disassembled with ease, transported to a new location or rearranged to accomodate additional modules over time. A 2 or 3 unit assembly can be turned into a 5 or 7 unit assembly over decades, providing financial freedom and flexibility for the homeowner. With the inherently environmentally friendly and affordable nature of building smaller, GoMicro means freedom and peace of mind.

Extended album here: http://imgur.com/a/umDfS

My website here: http://www.jacobgubler.com/GoMicro Prefab Module Render III

GoMicro Prefab Module Render II.2

GoMicro Novel Features

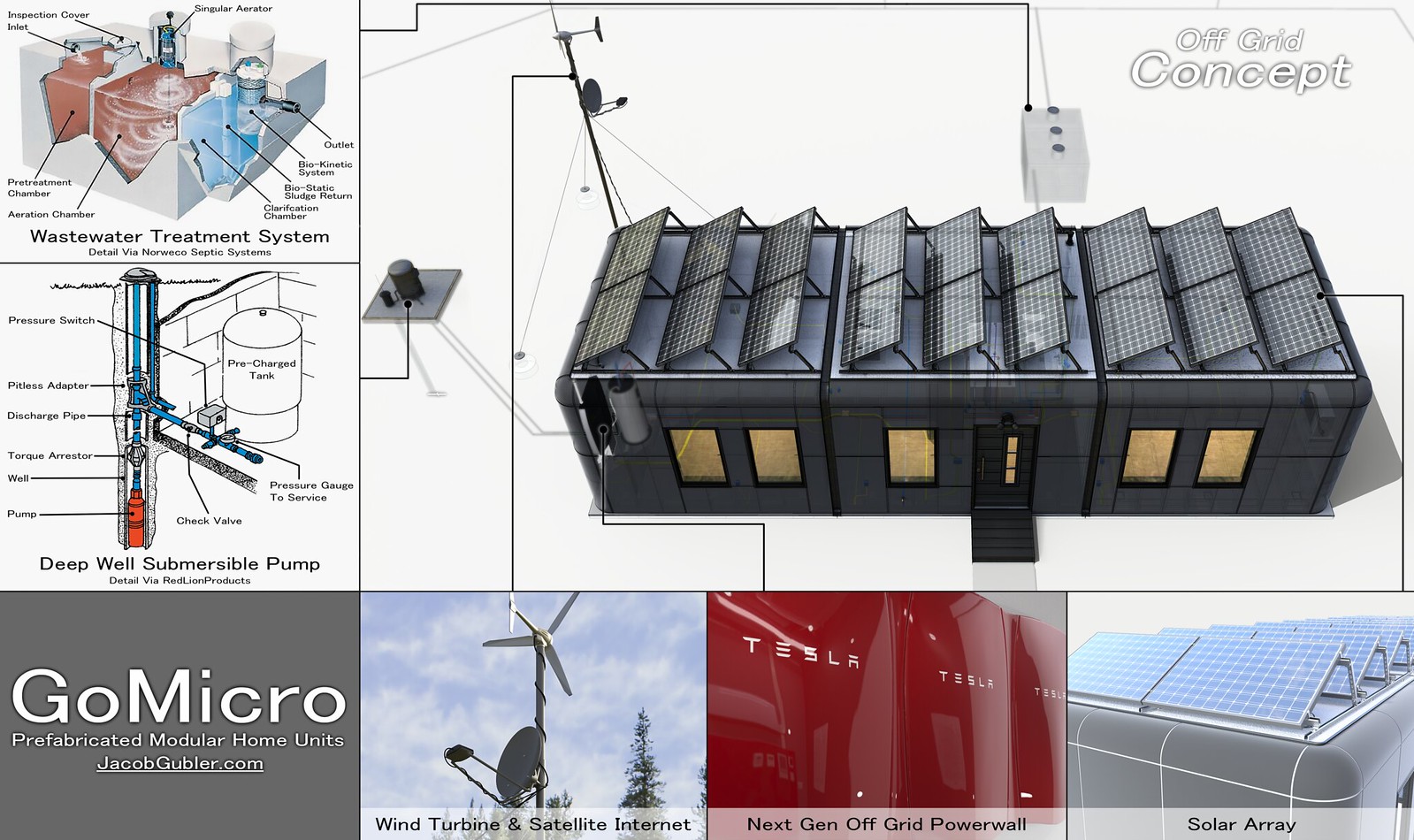

Off Grid Concept

Module Pricing and Variation

Construction, Transportation, Assembly and Expansion

2X Mid Module - Kitchen/Bathroom Option

GoMicro Warehouse Render

XRay Top Section II

XRay Ext Iso II

XRay Front Section II

Assembly Variation

Assembly Variation

Assembly Variation

-

Seems very well thought!

Does the production is yet started or all that is just conceptual?

-

@pilou said:

Seems very well thought!

Does the production is yet started or all that is just conceptual?

Thanks. All conceptual. Unless one of you can recommend a venture capitalist contact.

-

Some early/abandoned concepts

-

Wow, brilliant, you deserve a raise mate.

-

Impressive project, Jacob.

-

Great ideas, really well worked-out and presented.

-

very smart and well done -presented. gluck!

-

Great work

-

Do you have any problem with the model being slowed or complicated by elaborate (high poly) multi layered components as for plumbing fixtures and appliances?

-

Thanks everyone!

@pbacot said:

Do you have any problem with the model being slowed or complicated by elaborate (high poly) multi layered components as for plumbing fixtures and appliances?

Not so much. The file size never surpassed 80mb. Lots of repeated geometry. The piping/electrical is low poly for the most part, 12 segments a line, and there isn't much of it given the small scale. The warehouse render was pretty heavy - I made an empty warehouse a couple years ago and didn't yet understand how to optimize model performance with components, low-poly imperceptible detail and what not.

-

I really like the concept in general mate! I do have some questions and comments though.

What do you see the modules clad in and constructed of? By the images with rolled corners, one would assume aluminium? Cost here ($'s and environmental) would worry me!

What are you proposing as the structural framing, could this even be eliminated if sandwich panel construction was utilised? Ie: SIP type - Skin / EPS / Skin.

The installation direct to the ground is also an issue that would call for some serious ground works prior to installation, and then give rise to thermal transfer issues.

The beauty of all of this, you are thinking about new models for housing and that's always good!

-

@richard said:

I really like the concept in general mate! I do have some questions and comments though.

What do you see the modules clad in and constructed of? By the images with rolled corners, one would assume aluminium? Cost here ($'s and environmental) would worry me!

What are you proposing as the structural framing, could this even be eliminated if sandwich panel construction was utilised? Ie: SIP type - Skin / EPS / Skin.

The installation direct to the ground is also an issue that would call for some serious ground works prior to installation, and then give rise to thermal transfer issues.

The beauty of all of this, you are thinking about new models for housing and that's always good!

Thanks for the feedback Richard. Your modules were an inspiration and catalyst.

I imagined them clad in formed fiber cement paneling over waterproofed ply. The rounded nature would require special order, increasing costs for the FCP, underlaying formboard and carpentry. The sole motivation to keep them was a differeniating aesthetic that might be appealing to the Apple generation.

My intention was timber framing, a 2x6 exterior with a 2x10 subfloor and roof. For the 4X and 3X modules, 6x6 columns connected by 6x10's, with 2x10 subfloor and roof spans.

The main motivation to keep the subfloor was to create a module that can be shipped and transported at 95% completion. The subfloor framing not only allows for the means of connecting utilities between modules, but also for a factory-made finished floor, interior framing, cabinetry, etc., in addition to a simplified, more feasible means of relocating. Could the thermal transfer issues be remedied via an insulated subfloor? I imagine there need be some vapor barrier between the exterior bottom subfloor and slab (Aside from some goop around the base perimeter, which is a given).

What kind of groundworks do you forsee? I envisioned the modules fitted onto indentically dimensioned slabs with identical anchor bolt locations, plumbing waste penetrations (where necessary), and post-intallation waterproofing. Water supply can enter the exterior walls, intergrate with the water heater and inter-module piping. Electrical can do the same, all post initial installation.

-

@gubermensch said:

Thanks for the feedback Richard. Your modules were an inspiration and catalyst.

Wow, thanks mate! It was certainly a lot less complex than the project you've set yourself!

@gubermensch said:

I imagined them clad in formed fiber cement paneling over waterproofed ply. The rounded nature would require special order, increasing costs for the FCP, underlaying formboard and carpentry. The sole motivation to keep them was a differeniating aesthetic that might be appealing to the Apple generation.

I'd then imagine Aluminium might prove to be an alternative even on costs. I'd also look at if this could be false work so as to not require an added depth of engineering in the frame out.

Consider to that your aesthetic direction is giving rise to lots of further consideration of water and waterproofing.

@gubermensch said:

My intention was timber framing, a 2x6 exterior with a 2x10 subfloor and roof. For the 4X and 3X modules, 6x6 columns connected by 6x10's, with 2x10 subfloor and roof spans.

Mate I'd think about the option of SIPS or something your creative mind might come up with! Here is a link to a product I've been helping to develop the system for. Simply your FRC sheet glued to a Polystyrene insulative core. Given your module size, pretty much everything could be done with that and the result be RIGID!!!

Modular Building System | SipForm™ Structural Insulated Panels

Structural Insulated Panels | The SipForm™ Modular Building System offers builders an affordable, more efficient, high performance method of construction.

(www.sipform.com.au)

Here is another cool system using steel sandwich panel.

@gubermensch said:

The main motivation to keep the subfloor was to create a module that can be shipped and transported at 95% completion. The subfloor framing not only allows for the means of connecting utilities between modules, but also for a factory-made finished floor, interior framing, cabinetry, etc., in addition to a simplified, more feasible means of relocating. Could the thermal transfer issues be remedied via an insulated subfloor? I imagine there need be some vapor barrier between the exterior bottom subfloor and slab (Aside from some goop around the base perimeter, which is a given).

Mate here is then, what I'd suggest the weak point. That your site needs to be prepared well in advance of installation, with several additional transports to the site of everything from excavation, reinforcement and formwork, labour and concrete. Given the choice to go prefab is often remoteness, this double dealing of the floor will kill the costs.

@gubermensch said:

What kind of groundworks do you forsee? I envisioned the modules fitted onto indentically dimensioned slabs with identical anchor bolt locations, plumbing waste penetrations (where necessary), and post-intallation waterproofing. Water supply can enter the exterior walls, intergrate with the water heater and inter-module piping. Electrical can do the same, all post initial installation.

I think you have those covered mate! Though again the issue about the slab!

Mate I'd be lifting the floor off the ground so to be located on posts that can be installed in less than a day, or on installation of the pods.

Here is a link to the structural flooring product we've been using in combination with the SipForm panels - this can be engineered to create a chassis for transportables.

Spantec Steel Floor & Roof Frame Systems; Bearers, Joists, Piers, Bracing

Spantec Systems are Designers and Manufacturers of Boxspan steel flooring systems. We make joists, bearers, rafters, verandah beams plus piers and bracing.

Spantec (www.spantec.com.au)

With this flooring system, we've been using these footings. These are installed in about 10 minutes each, so could potentially be installed on the day of delivery of the modules, and their capacity is enormous! The guy who developed these will be a rich man.

http://surefootfootings.com.au/

The beauty is the site conditions and slopes you can install to is greatly increased and the effort / costs MUCH less. Suddenly your logistics are halved.

-

@richard said:

I'd then imagine Aluminium might prove to be an alternative even on costs. I'd also look at if this could be false work so as to not require an added depth of engineering in the frame out.

Consider to that your aesthetic direction is giving rise to lots of further consideration of water and waterproofing.

I didn't know the cost of an FCP system, even considering the extra engineering, carpentry and special order materials, would be comparable to aluminum. Thanks for the insight! I think waterproofing would be manageable, but I'm open to alternatives. I went with FCP for aesthetic again, something that has been around a while, but breaks the mold in this kind of presentation:

@richard said:

Mate I'd think about the option of SIPS or something your creative mind might come up with! Here is a link to a product I've been helping to develop the system for. Simply your FRC sheet glued to a Polystyrene insulative core. Given your module size, pretty much everything could be done with that and the result be RIGID!!!

Modular Building System | SipForm™ Structural Insulated Panels

Structural Insulated Panels | The SipForm™ Modular Building System offers builders an affordable, more efficient, high performance method of construction.

(www.sipform.com.au)

Here is another cool system using steel sandwich panel.

Wow, there are some brilliant building materials out there. The simplicity and ease of installation is impressive. How does the sipform system handle in-wall utilities? Or is there exposed piping/conduit?

@richard said:

Mate here is then, what I'd suggest the weak point. That your site needs to be prepared well in advance of installation, with several additional transports to the site of everything from excavation, reinforcement and formwork, labour and concrete. Given the choice to go prefab is often remoteness, this double dealing of the floor will kill the costs.

I think you have those covered mate! Though again the issue about the slab!

Mate I'd be lifting the floor off the ground so to be located on posts that can be installed in less than a day, or on installation of the pods.

Here is a link to the structural flooring product we've been using in combination with the SipForm panels - this can be engineered to create a chassis for transportables.

Spantec Steel Floor & Roof Frame Systems; Bearers, Joists, Piers, Bracing

Spantec Systems are Designers and Manufacturers of Boxspan steel flooring systems. We make joists, bearers, rafters, verandah beams plus piers and bracing.

Spantec (www.spantec.com.au)

With this flooring system, we've been using these footings. These are installed in about 10 minutes each, so could potentially be installed on the day of delivery of the modules, and their capacity is enormous! The guy who developed these will be a rich man.

http://surefootfootings.com.au/

The beauty is the site conditions and slopes you can install to is greatly increased and the effort / costs MUCH less. Suddenly your logistics are halved.

Right, I saw two mobilizations. Your typical sitework and slab pour, then the module delivery and installation. You're right, one mobilization would be ideal. The two systems you suggested here would remedy that perfectly and make it easier to transport in the future, a feature I was trying to maintain. In what I suggested, the module owner looking to move and sell their current property would have to deal with the slab and pour a new one at a new site; with what you suggested, the structural base and footings move with them. Brilliant!

Thanks for the insight and exposure to these systems.

-

@gubermensch said:

I didn't know the cost of an FCP system, even considering the extra engineering, carpentry and special order materials, would be comparable to aluminum. Thanks for the insight! I think waterproofing would be manageable, but I'm open to alternatives. I went with FCP for aesthetic again, something that has been around a while, but breaks the mold in this kind of presentation:

I think the problem with FRC is the cost for such a custom curve, where with Aluminium it's easy! FRC is I think generally made by pouring a slurry in a flat bed mould. You can imagine then the tooling required for a curve!

@gubermensch said:

Wow, there are some brilliant building materials out there. The simplicity and ease of installation is impressive. How does the sipform system handle in-wall utilities? Or is there exposed piping/conduit?

Mate, we try to put the plumbing to an internal (one off framed out wall) if not we just run a rod with big hot tip down the panel to create a pathway for pipes or conduits.

@gubermensch said:

Right, I saw two mobilizations. Your typical sitework and slab pour, then the module delivery and installation. You're right, one mobilization would be ideal. The two systems you suggested here would remedy that perfectly and make it easier to transport in the future, a feature I was trying to maintain. In what I suggested, the module owner looking to move and sell their current property would have to deal with the slab and pour a new one at a new site; with what you suggested, the structural base and footings move with them. Brilliant!

Thanks for the insight and exposure to these systems.

Yeah it will solve a LOT of issues, any reduce thermal loss to the ground. Here in Australia we wouldn't get away with timber on to the slab without some major nightmares with termite treatments.

-

@richard said:

@gubermensch said:

I didn't know the cost of an FCP system, even considering the extra engineering, carpentry and special order materials, would be comparable to aluminum. Thanks for the insight! I think waterproofing would be manageable, but I'm open to alternatives. I went with FCP for aesthetic again, something that has been around a while, but breaks the mold in this kind of presentation:

I think the problem with FRC is the cost for such a custom curve, where with Aluminium it's easy! FRC is I think generally made by pouring a slurry in a flat bed mould. You can imagine then the tooling required for a curve!

@gubermensch said:

Wow, there are some brilliant building materials out there. The simplicity and ease of installation is impressive. How does the sipform system handle in-wall utilities? Or is there exposed piping/conduit?

Mate, we try to put the plumbing to an internal (one off framed out wall) if not we just run a rod with big hot tip down the panel to create a pathway for pipes or conduits.

@gubermensch said:

Right, I saw two mobilizations. Your typical sitework and slab pour, then the module delivery and installation. You're right, one mobilization would be ideal. The two systems you suggested here would remedy that perfectly and make it easier to transport in the future, a feature I was trying to maintain. In what I suggested, the module owner looking to move and sell their current property would have to deal with the slab and pour a new one at a new site; with what you suggested, the structural base and footings move with them. Brilliant!

Thanks for the insight and exposure to these systems.

Yeah it will solve a LOT of issues, and reduce thermal loss to the ground. Here in Australia we wouldn't get away with timber on to the slab without some major nightmares with termite treatments.

-

Great communication in the images reminds me of loft cube:

-

Great concept, modeling and presentation.

-

Well done Jacob, great concept and excellently presented. I'm glad to see you getting great feedback from Richard. Maybe you could team up with him and get the concept to prototype and to the market!

Advertisement