Cutting up a model for 3D printing

-

revelever: FYI, You may not have found this but Shapeway has a free cloud based service wherein they run checks on your model, more extensive then NetFab free, check their web site. BTW they have a limit on model size and number of polys ( 64 MB and 1,000,000).

Here is link http://www.shapeways.com/tutorials/how_to_use_meshlab_and_netfabb. I think most printer have to use slicer to print the item since they lay down a small layer at a time. I was initially concerned about your model and possible issues running into small sections that are not supported. -

@mac1 said:

revelever: FYI, You may not have found this but Shapeway has a free cloud based service wherein they run checks on your model, more extensive then NetFab free, check their web site. BTW they have a limit on model size and number of polys ( 64 MB and 1,000,000).

Here is link http://www.shapeways.com/tutorials/how_to_use_meshlab_and_netfabb. I think most printer have to use slicer to print the item since they lay down a small layer at a time. I was initially concerned about your model and possible issues running into small sections that are not supported.Interesting I will certainly check that out. However I don;t think Shapeways uses 'out in the open' desktop class FDM printing,, but rather an SLS process which works in a sand bed so their support criteria is going to be different...i think. But I should check it out before I say anything more. I have done 2" bridging on this printer pretty successfully, so I am not concerned about the loop parts on the rim for example. You can get away with some pretty crazy overhangs and bridges in mid air with an FDM printer as long as you set your toolpath velocities and fan speeds right.

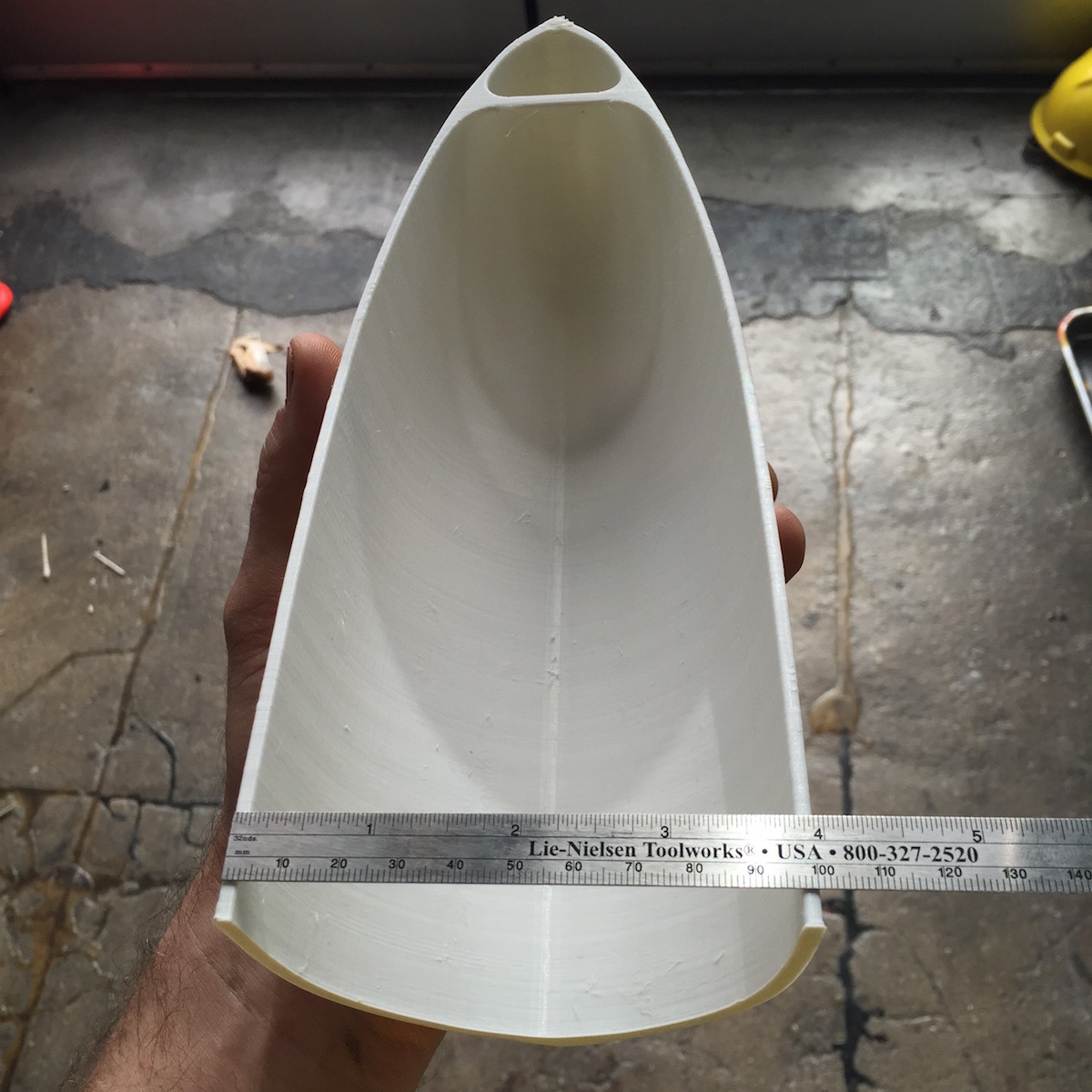

The print actually came out quite well, I'm doing the other half right now. Slicing is quite a powerful thing!

The aforementioned bridge did have a flat bottom as opposed to a bellied one, but its pretty subtle. Re slicing the model a little lower on the Z axis or closer to the bottom of the hull would take care of this issue.Here are some pics

-

That looks great !!

Perhaps when I finally put my CNC at work I will buy some printing attachments too. -

@ely862me said:

That looks great !!

Perhaps when I finally put my CNC at work I will buy some printing attachments too.What kind of CNC are you building? What is the Z axis movement? That is one of my next projects!

-

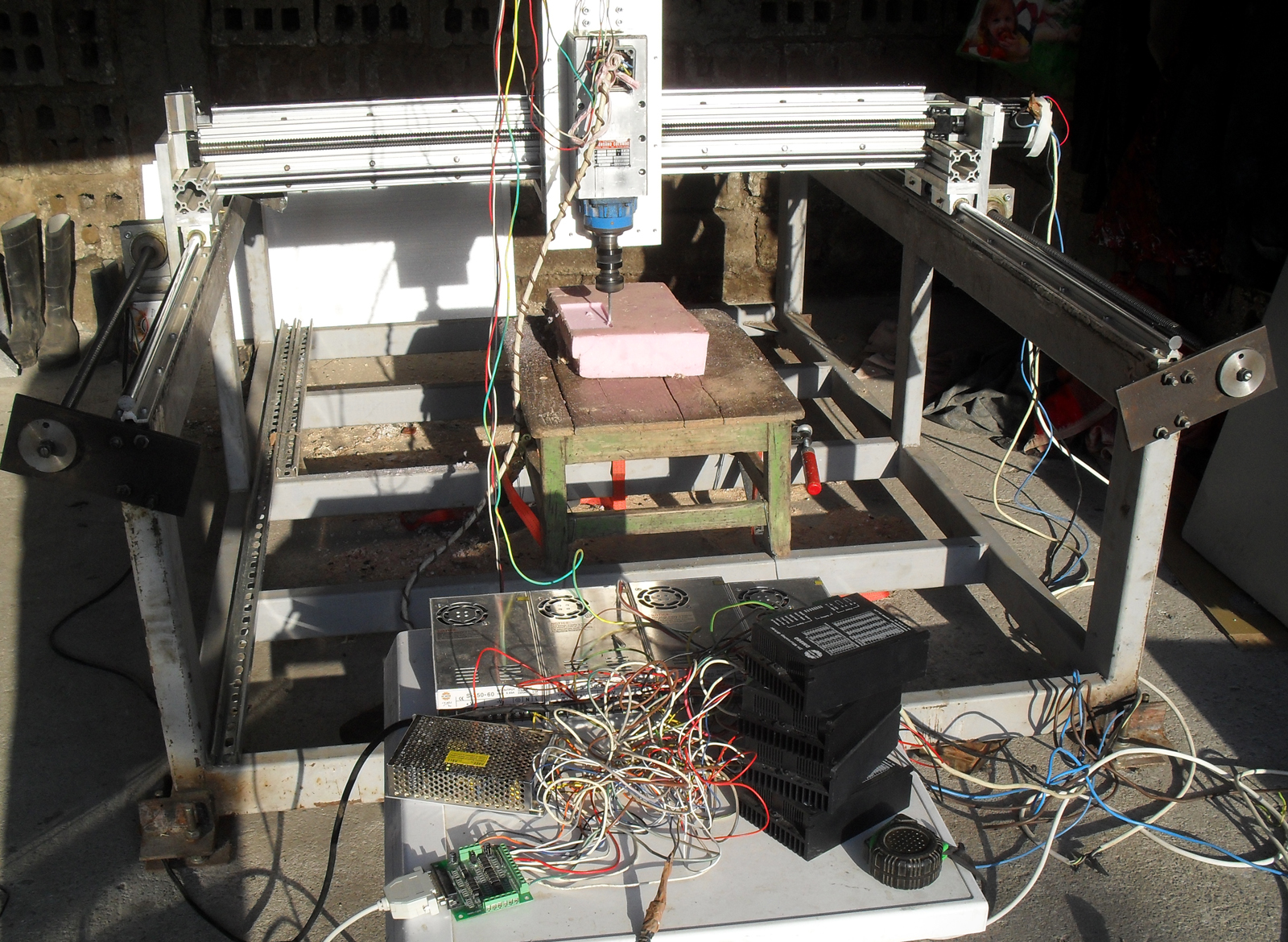

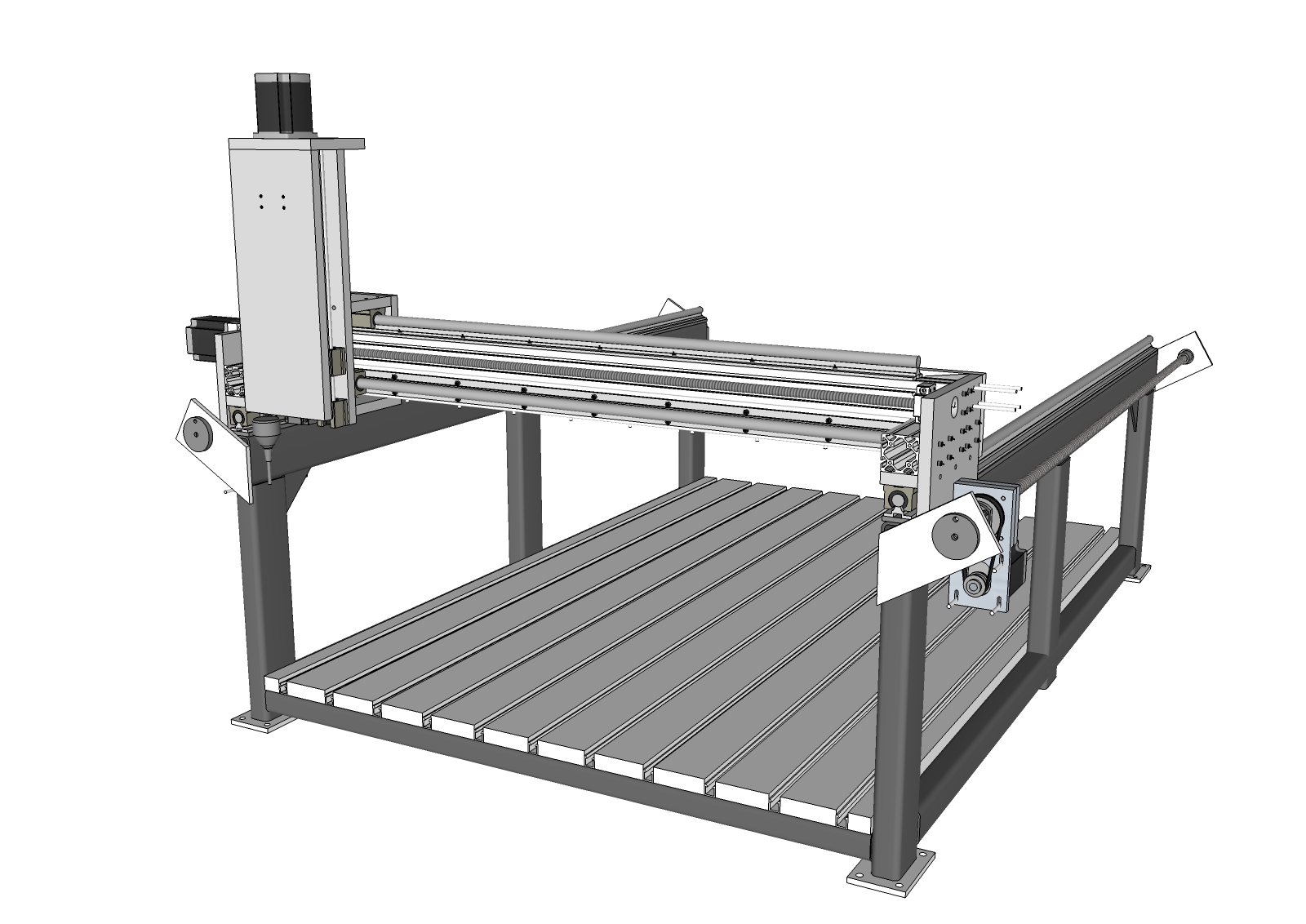

This kind of CNC. Took me a while to build and it is still far from complete.

The Z axis travel should be over 350mm, X is 1750mm and Y is 1100mm.

These are my first real attempts. Some models done for my sister in law - she's a kindergarten teacher. And a stepper motor cover done in foam- just for testing the code.

Sorry to somehow hijacking the thread.

-

@ely862me said:

This kind of CNC. Took me a while to build and it is still far from complete.

The Z axis travel should be over 350mm, X is 1750mm and Y is 1100mm.

These are my first real attempts. Some models done for my sister in law - she's a kindergarten teacher. And a stepper motor cover done in foam- just for testing the code.

Sorry to somehow hijacking the thread.No I invited the thread jack. That is a very badass CNC btw.

Here are some pics of the final product. Definitely room for improvement but overall it came out very well, client happy etc.. Thank you for all the help guys, It really was invaluable!

Advertisement