[Poll] - engineer this table

-

• high volume cafe/coffee house..

• one of those "i don't know - what do you want to build?" setups

• i want to build thisi'm not 100% on these spans/overhangs though.. what do you think?

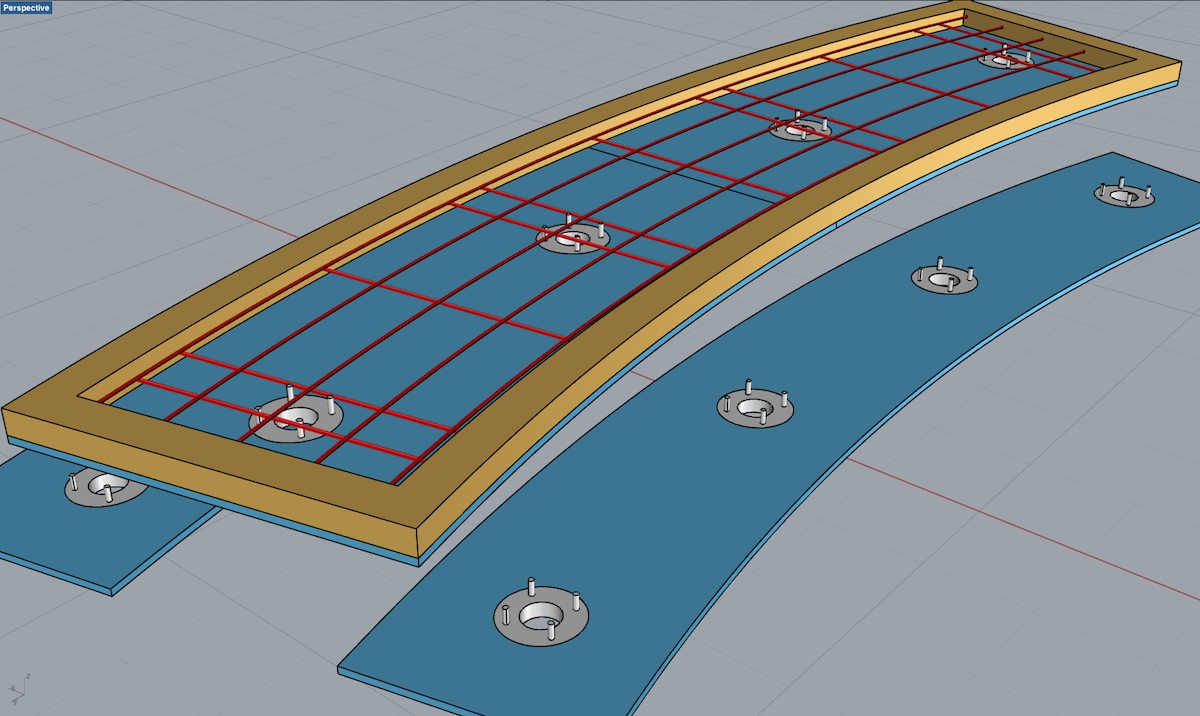

• 2.5" thick 6000psi concrete

• #3 rebar as shown-- cross bars are welded to bolts coming up through the flange then the long spans are tied in normal

• 12'-3" overall length of the top-- longest span between flanges = 34.5"

• 30" deep table -- overhang from flanges that way is 11.25"

• uprights are 3" sch40 steel pipe (3.5" o.d)

• test render is with 4" pipe - cost concerns brought it down to 3" so not quite as stout as shown in the render.

• floor flanges bolted to the floor-- that's all the mounting which is happening down there.. the idea is that this curved shape offsets the uprights enough so it's free standing without bolts.. then the bolts give it added prevention from toppling.

• ~1/4yd concrete :: ~1000lbs. (ie- pour in place )

)

-

That thing could hold up a Mack truck...

-

@krisidious said:

That thing could hold up a Mack truck...

ha.. yeah

i mean, i'm leaning in that direction myself.. it's just that i've never spanned anything with 2.5" thick concrete.. i've done it with 6" thick and it was totally fine with people jumping (skateboarding) on it etc..so 2.5" seems thin to me but it's possibly thicker than someone might use for a countertop type application..

i don't know.. if i'm only 90% sure, the 10% doubt is enough to make me worry.. just seeing what others think.

thanks for your input. -

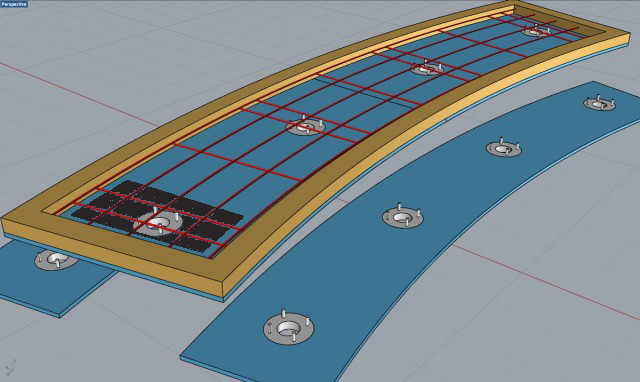

I'm pretty sure you could get away with just fiber mud, but I would want a layer or two of wire welded mesh or rebar in that seat, I see you drew it for the top but not the seat? I think the seat might need it more... Especially here in America.

-

Kris makes a good point about the seats needing some r-bar./wwm.

Also, you may want to consider core drilling @ the table and seat bases.(& don't assume clear drilling)

..........otherwise......

..........otherwise......  ...

...  ......

......  ......

......

C

-

I know you'll be careful, but 1" minimum coverage on the steel might result in "telegraphing"? Anyway, 6000psi is mighty strong.

-

@krisidious said:

I'm pretty sure you could get away with just fiber mud, but I would want a layer or two of wire welded mesh or rebar in that seat, I see you drew it for the top but not the seat? I think the seat might need it more... Especially here in America.

oh.. right.. i didn't finish drawing yet

.. there will be some steel in the seats too

.. there will be some steel in the seats too@unknownuser said:

Also, you may want to consider core drilling @ the table and seat bases.(& don't assume clear drilling)

..........otherwise......

..........otherwise......  ...

...  ......

......  ......

......

hmm. i'm not sure i quite follow what you're saying? what do you mean?

@mitcorb said:

I know you'll be careful, but 1" minimum coverage on the steel might result in "telegraphing"? Anyway, 6000psi is mighty strong.

you're talking about keeping the steel away from the edges? if so, yeah, i'll be more than an inch away (not by much) but i'll be hand packing the concrete and will need room for my fingers to get in there

..i am a little worried about the rebar (rust) bleeding through to the surface though.. i'd like to just use a galv/zinc mesh but i'm not sure about using such thin wire across those spans.

..i am a little worried about the rebar (rust) bleeding through to the surface though.. i'd like to just use a galv/zinc mesh but i'm not sure about using such thin wire across those spans.and yeah, i know 6000psi is strong.. and i also realize that some of what would constitute the table breaking would be compression.. but i just look at that rating as how much psi you can put on top if there's a sub-base (dirt) underneath the entire piece.. so i'm not sure how 6000psi translates when dealing with spans/cantilevers.

-

I assume you are using a mold...

We made some benches similar to this. We used white cement (And acid colored them after). We used fiber reinforced concrete. First we laid in a layer of mud about an inch and a half thick then laid in a layer of stucco expanded mesh which we tamped just into the mud. Then we ran 1/4" rebar longitudinally on 4 " centers. Covered it with a little more mud. Dropped in one more layer expanded mesh, and capped it with mud. We were at 3" total, and it was HEAVY. But, after the acid stain, looked like a granite slab -

@futurepast said:

I assume you are using a mold...

right.. that's what the drawings are of.. i have to pour it in place since it's so heavy and no machinery access.. if i could just pour it then lift it into place, it'd be a lot easier to form.. but being up in the air, i have to make the forms in a way that they're used for post alignment, hold wet mud, then easily removable afterwards (which is a bit tricky with those posts.. but yeah, the form work is the bulk of the work.. the actual pour won't take more than a couple of hours.

@unknownuser said:

We made some benches similar to this. We used white cement (And acid colored them after). We used fiber reinforced concrete. First we laid in a layer of mud about an inch and a half thick then laid in a layer of stucco expanded mesh which we tamped just into the mud. Then we ran 1/4" rebar longitudinally on 4 " centers. Covered it with a little more mud. Dropped in one more layer expanded mesh, and capped it with mud. We were at 3" total, and it was HEAVY. But, after the acid stain, looked like a granite slab

yeah, i've wet set rebar before but i'd rather not.. if the steel is pre-placed etc, one less thing to worry about while pouring

i've seen some of the decorative stuff with acid/dyes/exposed aggregates.. i'm still not sure which direction I'm going to go with that part.. but probably just hand troweled finish with maybe a semi-glossy epoxy sealer. -

One more thing....if you are going to do it in place, DON'T strip the forms to soon!!!! The concrete at that thickness will dry out too fast as it is. Keep it damp (burlap bags etc.)

-

@unknownuser said:

Also, you may want to consider core drilling @ the table and seat bases.(& don't assume clear drilling)

..........otherwise......

..........otherwise......  ...

...  ......

......  ......

......

@unknownuser said:

hmm. i'm not sure i quite follow what you're saying? what do you mean?

Jeff,

I used to do a fair bit of commercial work (restaurant/bar/etc.).

Often the tables and chairs (similar to your design) were installed using a core drill and grout.You simply drill the appropriate size hole in the conc. slab, and set the round base in the hole and grout.(brace plumb/level)

Obviously you have to be cautious of what is "in" the slab, and or, the type of slab. (post tension?)

So rather than rely on bolts (expoxy set?/wedge anchors?) as in your design, core drilling would potentially be a stronger/tamper proof option.

Just My 2¢

Charlie

Edit:

PS.......you may want to explore buying the bases instead of custom fab. (Outwater Plastics?) -

oh, I see what you're saying now. but the way I plan on building it, I won't be drilling into the slab. the flanges/legs are already placed during the pour.. the bolts coming through the top flanges are already there when the mud is wet (and welded to the rebar)... those bolts are what will allow me to suspend the rebar without any seats or hangers etc messing up any of the surfaces

as in- if this thing ever moves to a new location, you're only unbolting the floor flanges as the top flanges are not coming off.. moves as one (though I suppose you could unscrew 3" pipe leg from the top flange)

but in the drawing, the blue represents melamine.. holes are cut in it for the flanges etc.. or- that (partial) drawing is the form work and it's how it will look prior to pouring

-

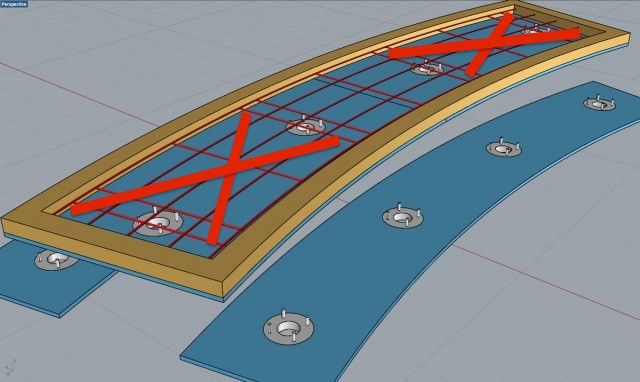

Curious in your drawing, I don't understand what is the gold versus blue component? I would think there needs to be some steel tie from each post cross wise in the table top, either in the rebar welded to the post or a plate, for torsion in the long axis. Some of this is resisted by the curved placement of posts. If someone sits on the corner is there a lot of tension in concrete at the top of the post?

-

@pbacot said:

Curious in your drawing, I don't understand what is the gold versus blue component?

the actual color is just 'color by layer' and isn't meant as a material/texture representation.

but the blue is 3/4" melamine sheets.. the gold is the form boards for the sides..

basically, everything in the drawing aside from the steel will be removed once dried.. or- when finished, you won't see any of the stuff in the drawing.. you'll only see stuff that isn't in the drawing (concrete)

(concrete)@unknownuser said:

I would think there needs to be some steel tie from each post cross wise in the table top, either in the rebar welded to the post or a plate, for torsion in the long axis. Some of this is resisted by the curved placement of posts. If someone sits on the corner is there a lot of tension in concrete at the top of the post?

that's my main concern as well.. structurally, i'd like to place vertical supports at the corners but people's legs need to be able to freely move in/out of the there so that's why the posts are in the middle..

but yeah, concrete can handle the torsion/twisting forces which will be happening in those areas.. problem is, i don't know exactly how much nor do i know how to calculate those forces..

i did consider something like so but it's generally not good practice to triple+ stack rebar which would happen if i used the same layout.. (especially when considering the top is 2.5" thick and each layer of rebar is 3/8")

i'm also looking into GFRC (glass fiber reinforced) which, as i understand, has great flexural strength and in many instances, eliminates the need for steel. (though i'd still use steel in combination with the fiber)

-

Jeff,

Just spitballing here........what if you router out your bottom form for a ¼" steel plate.(finishes flush to bottom of conc.) Also weld the plate to the sched. 40 steel pipe.

(see my crude image below)

And I'm curious...were you going to fill the sched. 40 with conc. as well?

C

-

hmm. that would work as a means to get more support in those area.. you wouldn't have to rout a recess in the form.. just place it on top of the form then it will be flush with the bottom of the concrete.. it would also double as a cap for the pipe (as in- those pipe holes will be covered and I'm not pouring inside of them.. so it would just be drilling the four flange holes into the steel plate..

thing is, I'd rather not if it's not necessary. or-- it still doesn't make me 100% confident.

meh, maybe I'll just talk($) to an engineer about it.

-

Hmmm. You need a friendgineer.

Can't believe it would be that expensive.

Can't believe it would be that expensive. -

@mitcorb said:

Hmmm. You need a friendgineer.

Can't believe it would be that expensive.

Can't believe it would be that expensive.heh.. i have one of them and he'd probably have a look for no charge.. thing is, he's not in the 'immediate' circle of friends so i don't want to waste a possible favor with this table..

but yeah, i'll just show it to a local engr.. surely won't be more than a couple hundred. -

I haven't looked at it carefully, but have you considered other materials. Good ply and nice edge trim, light and easily replaced.

Or fibreglass, simple fabrication, durable, light etc etc

Epoxy casting, bloody expensive but wonderful finish.I think my point could be that it depends what the full end use is. Are you making one or 300? Is tooling up cost effective etcetc

-

@box said:

I haven't looked at it carefully, but have you considered other materials. Good ply and nice edge trim, light and easily replaced.

Or fibreglass, simple fabrication, durable, light etc etc

Epoxy casting, bloody expensive but wonderful finish.I think my point could be that it depends what the full end use is. Are you making one or 300? Is tooling up cost effective etcetc

first thought was wood since i'm a woodworker.. (and this is still, basically, a wood project.. the form work is what will require the most skill).. i already have the necessary tools to build this.. concrete or rebar isn't that expensive..

the most expensive thing in the design are the flanges/threaded uprights and i'd have those subbed out. (~ $50 per flange / $50 per upright)..but that stuff aside, i'd still be up against the same sort of issues if i just took the same shape and made it of a different material.

i'm making a total of 4 different pieces.. a bar and 3 tables.. none are the same shape and the forms will be trashed (about $500 in form material)

Advertisement