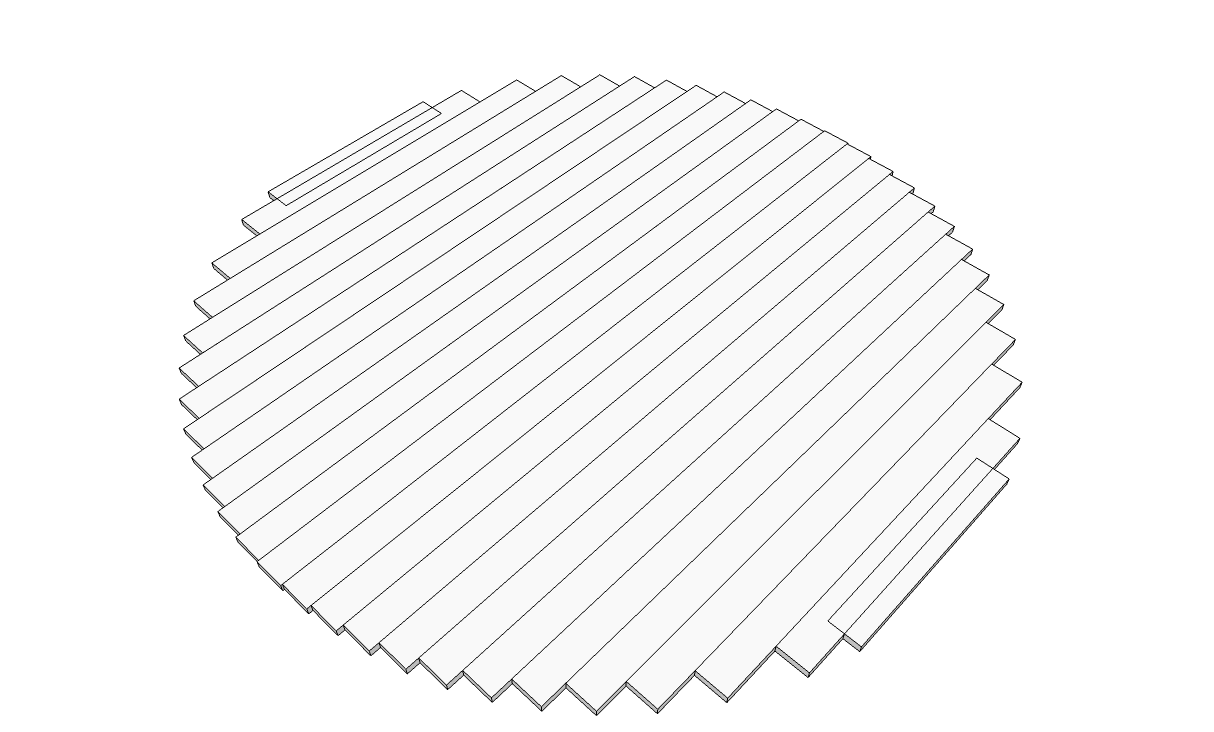

Cutting floor boards out of a cylinder

-

Thanks. I did as you indicated and it worked very well. One final question: After deleting the waste, I'm left with planks that are open on the now curved ends. How should I make them solids again?

-

It sounds to me as if you didn't copy the cylinder into those components/groups before doing the intersect. By copying the cylinder in, when you delete the waste, you're suppose to be leaving part of the cylinder behind to make the curved surface. If you don't paste the cylinder inside the component, there won't be any face to leave.

At this point you could stitch the faces closed by drawing vertical lines between vertices or you could delete one face and the verticals and use Push/Pull to pull the plank back to 3D.

-

Does sections are like these ? So the Push Pull one face will don't working!

-

@unknownuser said:

Does sections are like these ? So the Push Pull one face will don't working!

He said he was going to join the planks with dowels which I think would mean there aren't tongues and grooves on the edges so then Push/Pull would work fine. If the planks are joined with tongue and groove joints, it would be best to just redraw the entire plank and cut the ends off as I described.

-

Thanks again. You're right that I neglected to "copy" the cylinder into the model. I did as you suggested and restitched the vertices from the top to the bottom of the circles ( I now see the downside of specifying a lot of "sides" when drawing a circle).

My next challenge is drawing the dowels, which are inserted into the edges of each plank, thus joining it to its neighbor. [Pilou, pls note that these are not typical flooring boards with the tongue and groove profile you suggested. The sides of the planks are smooth and holes are drilled to accommodate the dowels.] I was thinking I would draw the circles for them and then push/pull the hole into the edge of one plank and then try to copy the holes into the neighboring plank somehow. Would the rotate tool be best for this? Is there a faster way to do this for all the planks? Thanks.

-

So since you have the planks drawn and cut, try it this way:

- Lay out the circles for the holes on the edge of a plank.

- Select them and Ctrl+C copy.

- Use Push/Pull to push in the the holes to depth.

- Close the first plank and open the neighbor.

- Click on Edit>Paste in place.

- While the pasted circles are still selected, use Move-Copy to copy them to the opposite edge of the plank.

- Return to the first edge of this plank and push in the holes.

- On the second edge, add or subtract holes as needed.

- Select and Ctrl+C copy the circles.

- Push in the the holes.

- Open the next plank and go up to step 5 and repeat.

There's a cool plugin from Wudworx that would make this a lot easier but I would suggest that you learn this with the native tools first.

-

So if your plank are strictly "box plank" maybe Slice v5 by Tig will be a cool friend! ?

(but without an image of one of your plank...maybe i am wrong

No plank to draw!!!

Just draw a disc then and the plug make all the rest!

At the end if you want that each different plank must be a component oe a group there are plugins for automatically made that!

-

Pilou, Slicer is nice for a lot of things but I don't think it is the right option for this. The OP clearly stated the planks are of varying widths and he wants the ends cut to the radius of the cylinder. Slicer only makes constant width slices and doesn't retain the radiused ends.

-

Will you be showing the dowel pattern here?

-

Ah damned, I am disappointed!

So TIG must improve his plugin!

-

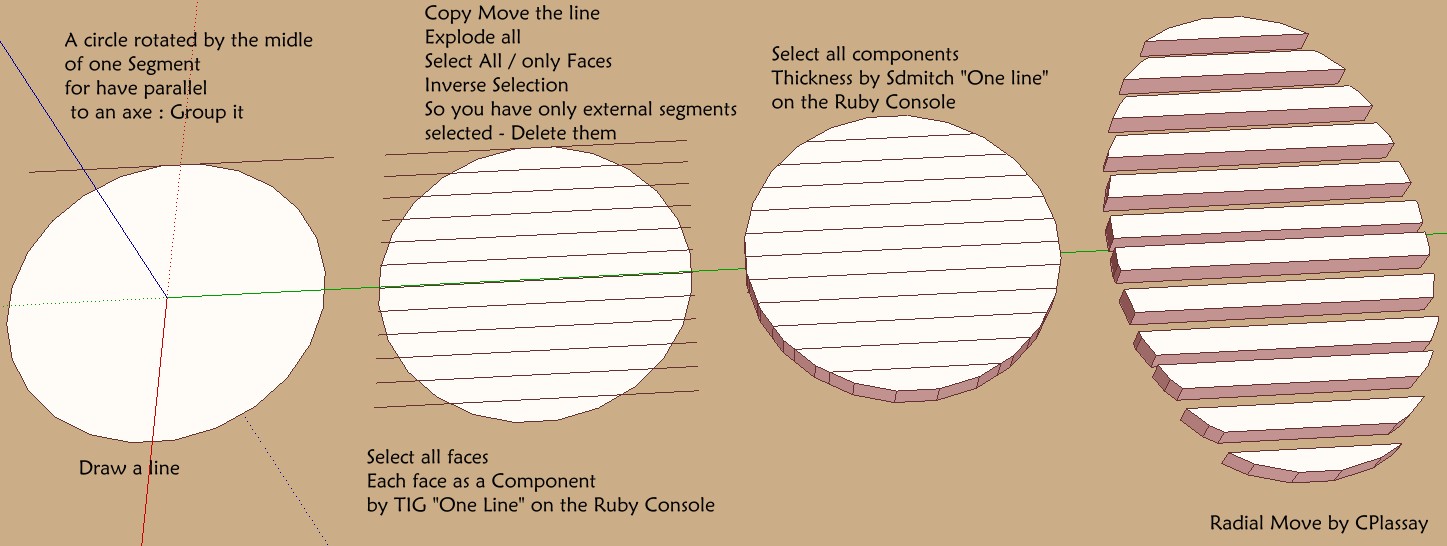

So my try

The two "one line" must be a "real one line" written inside the Ruby Console !

Face on Component by TIGm=Sketchup.active_model;n=m.active_entities;m.selection.to_a.each{|e|(g=n.add_group(e);g.to_component.definition.name="Face#1")if e.class==Sketchup;;Face}Thickness of a component By SDmitch

mod=Sketchup.active_model;sel=mod.selection;sel.grep(Sketchup;;ComponentInstance).each{|c| c.definition.entities.each{|f|(f.pushpull -10;break) if f.class==Sketchup;;Face}}Selection Toy by Thomthom

Inverse selection by TIG

Radial Move by CPlassais

PS Maybe following your version of SU when you "Explode all" , Faces are not trimed by segments ?

So Select all / Intersect Selected

-

Anything to keep from using the native tools.

-

Not sure you can easily take away pieces between them without plugin!

For ten pieces maybe but for 100 ? -

Thanks. I've finished the floor boards (yes I put it down for a while). Now I've got a lot of dowel holes in the planks w/ no dowels. Making a dowel is easy, but how would you suggest I insert a copy of it into each of the holes? Is there some way of doing this quickly and accurately?

-

Make the dowel a component and set its origin and axis alignment so you can simply drop the components in to place. Did you use even spacing between holes? Could you either post the model or at least a screen shot in X-ray mode so we can see the arrangement of the holes??

Advertisement