3D printer can build a (real) house in 20 hours!

-

Fantastic ¡

a complete revolution is just close to arrive -

There was a point raised in the video by Prof Khoshnevis where he addressed, what happens to construction workers with all this automation?. His answer is logical, much the same thing will happen to construction workers as happened to people working on farms after the introduction of mass mechanisation.

I would however be slightly skeptical about the materials he is intending to use, particularly concrete, at least in its current 'standard' form. Like current 3D printing for small items, new materials are needed and I see new innovation coming into play in this area also. I am talking, of course, about sustainable materials and the most obvious one is timber.

Its also crossed my mind, why should a dwelling house have to last 100s of years! I think it would be far more practical if one was designed to last for no more than 30 -40 years. I reach this figure by calculating the time a family might need one! The parents move in at 30ish, raise a family and by the time they reach 60 / 70ish they require a different type of dwelling unit. The dwelling is then re-cycled and 're-printed' on the same plot of land to suit their new needs, maybe a smaller unit with a bigger garden area or a twin use, starter home and retirement home on same plot!

This type of regeneration might also be good for communities as they would become far more mixed with starter homes, family homes and retirement homes all in the same area and continuing to change status. This type of mix would, I feel, would have many more advantages over the current situation with homogeneous 'fixed' units.

-

What DID happen to the farmers? Not that nice really--rural communities still reeling, few "farmers" and the remaining work is mostly done by low-paid, often abused, itinerant workers etc. But that's not to say there are other ways to approach progress.

I think the structural reinforcement visualization is unlikely but hey, I'm no engineer (or professor). They'll find more direct ways I bet.

Regarding recycling buildings see "How Building Learn" and "Cradle to Cradle" (books).

-

@pbacot said:

What DID happen to the farmers? Not that nice really--rural communities still reeling, few "farmers" and the remaining work is mostly done by low-paid, often abused, itinerant workers etc. But that's not to say there are other ways to approach progress.

I think the structural reinforcement visualization is unlikely but hey, I'm no engineer (or professor). They'll find more direct ways I bet.

Regarding recycling buildings see "How Building Learn" and "Cradle to Cradle" (books).

I take your point about how it seems that there is some possible abuse on the larger farms but I would also mention that, over here, in any case, I am seeing a lot of quite intensive Organic Farming taking place. This type of farming / growing is labour positive in the good sense.

Thanks for mentioning "How Building Learn". I did a search and located the following on You Tube. Its over 3 hours but I imagine interesting so I intend to watch soon.

How Buildings Learn - Stewart Brand - 1 of 6 - “Flow”

http://www.youtube.com/watch?v=AvEqfg2sIH0 -

These are eeirly familiar, only with a modern twist to Edison's prefab concrete house concept.

But I really think that the 3d printer is going to change our lives much like the computer did. http://exhibits.mannlib.cornell.edu/prefabhousing/prefab.php?content=two_a

-

Sorry I meant "How BuildingS Learn". I don't think I've seen the video.Thanks.

Yes, I was an organic farmeworker (on my friends' piece) in my younger years. We had a blessed niche situation and I think many people have plugged into that sort of thing.

-

Peter, I realised it was a typo

Dale, I see Edison gave up on the idea after he discovered that timber frame construction was cheaper. I also think that the use of timber in some form other than tree cuts might be a viable alternative to concrete.

-

It's the materials that will make the difference in 3d printing. I had read about this development a while back http://news.softpedia.com/news/MIT-Experts-Develop-Advanced-3D-Printer-221714.shtml

MIT Scholars have developed there 3d printer so it can vary the density of the material it prints. In this article they site the fact they can emulate the structure of bone using concrete. This is really fascinating.

Visionaries in this field picture the day when virtually everything will be available via 3d printers.

As for poor Edison I guess a set of forms worth 25K was a shocker in an era where you could order a house from Sears for $2500.00. -

Watched the video, interesting indeed. Imitating how bones and palm trees are made up is the way to go

At least TE got other inventions right. He obviously didn't put the 99% perspiration into his house manufaturing process

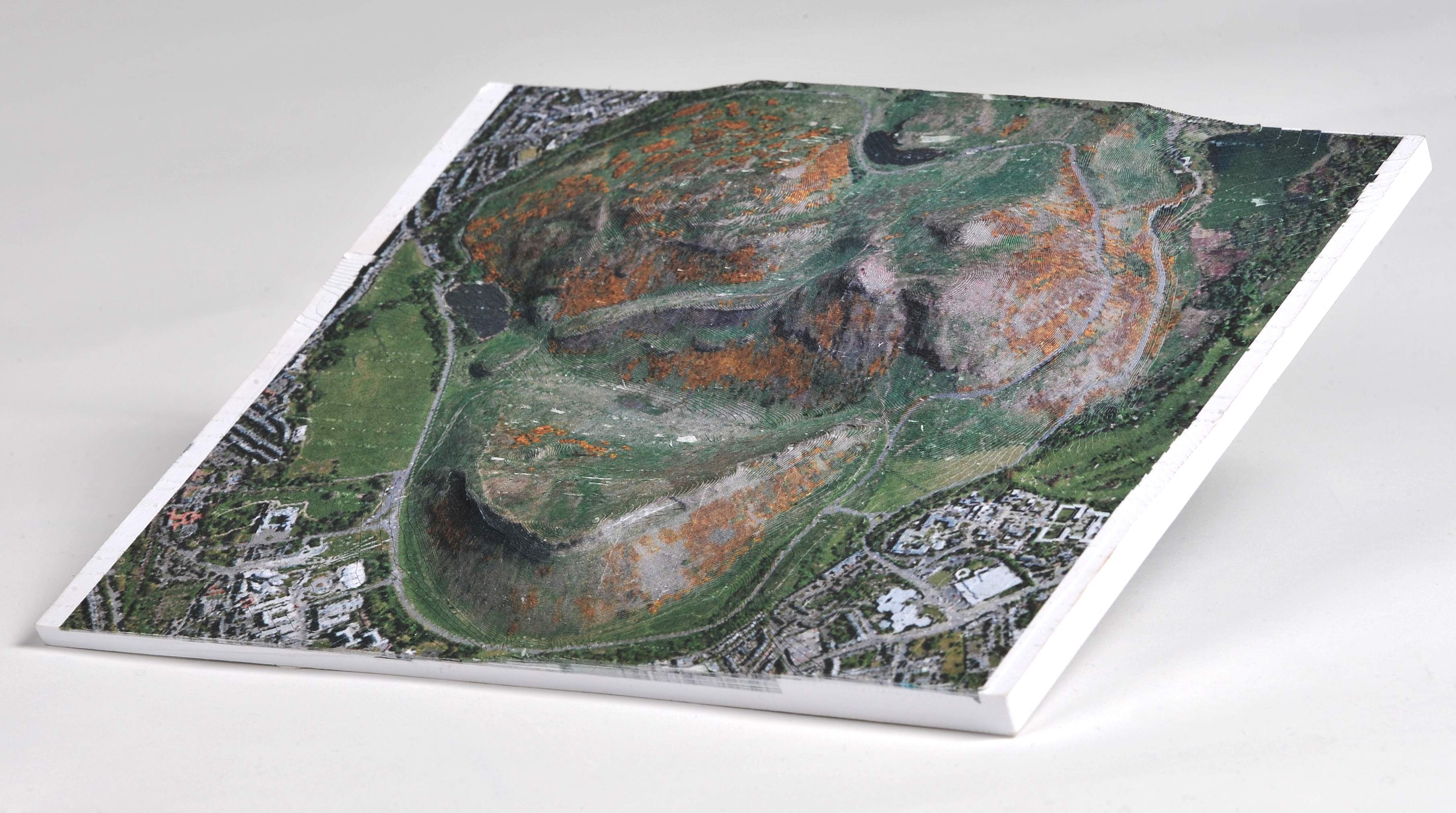

On the subject of materials for 3DP. A new Irish firm, Mcor Technologies, have come up with a system that uses paper sheets.

The results look to be good for architectural models. http://www.mcortechnologies.com/

-

Wow Mike! I want one of those! The one thing that is also very exciting about this is that there will be lots of work for good 3d modelers. And I think John Bacus is a 3d printing fan so I'm hoping SketchUp will follow.(There is the exporter announced at basecamp)

-

I contacted Mcor Technology to see if there was a possibility of seeing and actual 3DP. They may send one. Here are some large images they sent me.

-

I think a few brick production companies will be doing Patent searches right now!

I think even Mr Kodac may be looking into it

-

Loughborough University and Fosters have been researching printing 3d concrete elements too...

http://www.youtube.com/watch?v=EfbhdZKPHro

and

http://www.youtube.com/watch?v=TLSuqo6oTeo

and then there's the Robo building Machine

http://www.youtube.com/watch?v=3fhryxVAsa4

and of course if you are peckish you can print some food

http://www.youtube.com/watch?v=x6WzyUgbT5A

Advertisement