What's this?

-

So.....not what you were looking for?

-

Not quite Steve

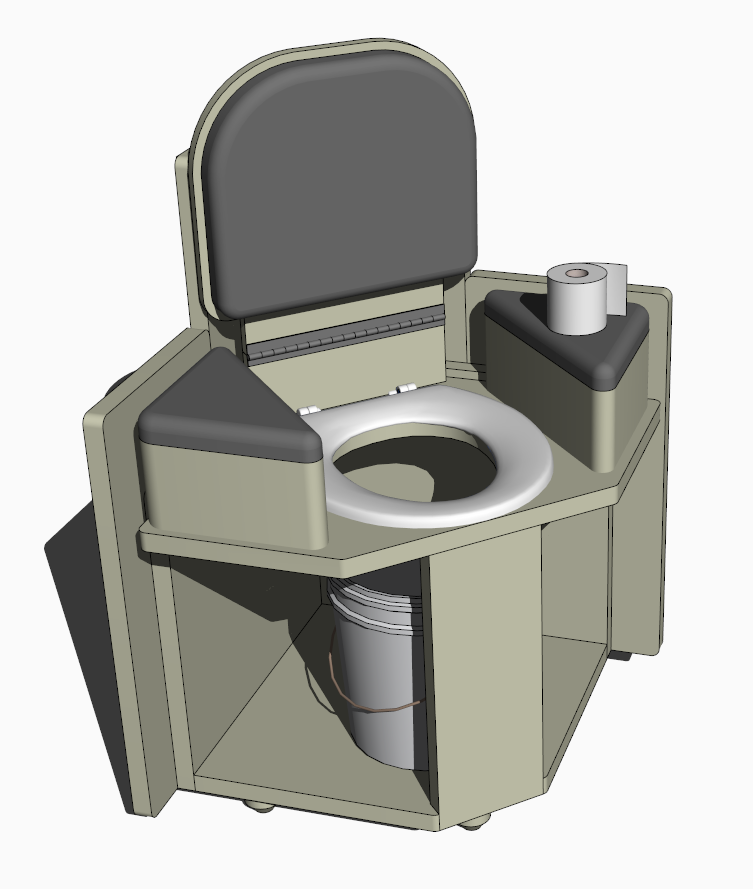

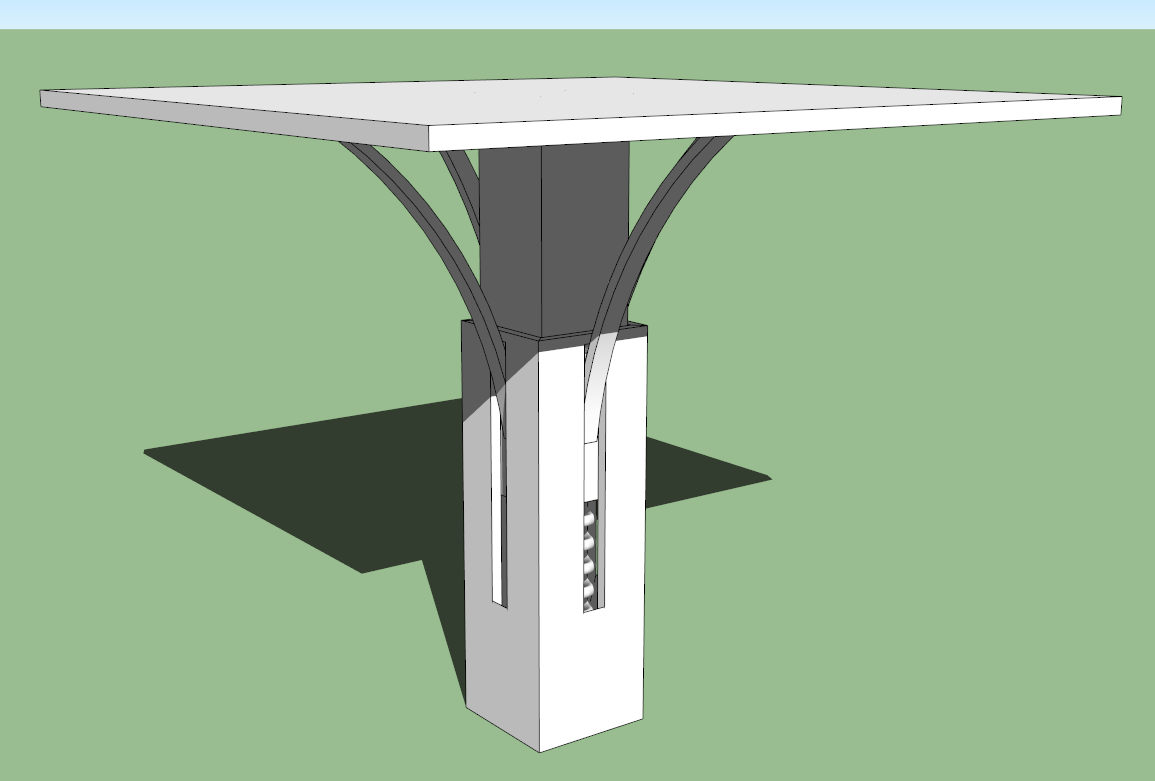

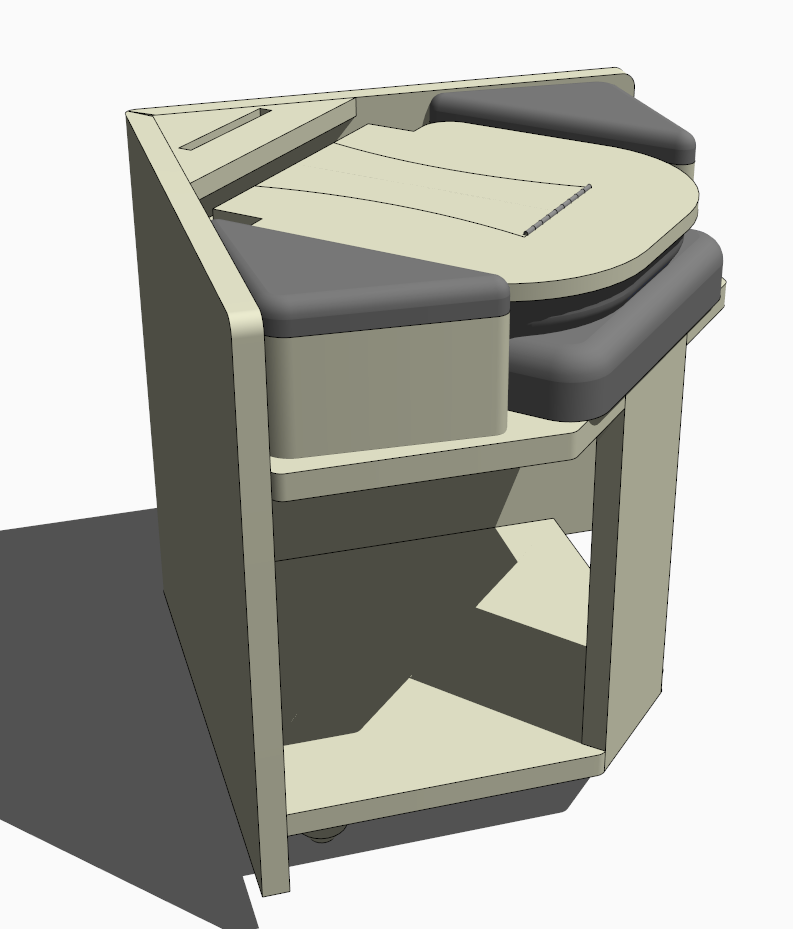

Anyway, did a bit more on it. I went with an octagonal top and used dowels to get around the Coffee and Dining heights. It would be a mater of lifting the table out from the coffee table position, turning it 45 degrees and popping it back into the slots for the dinging position. I imagine is these dowels were hardwood they would be reasonably ridged.

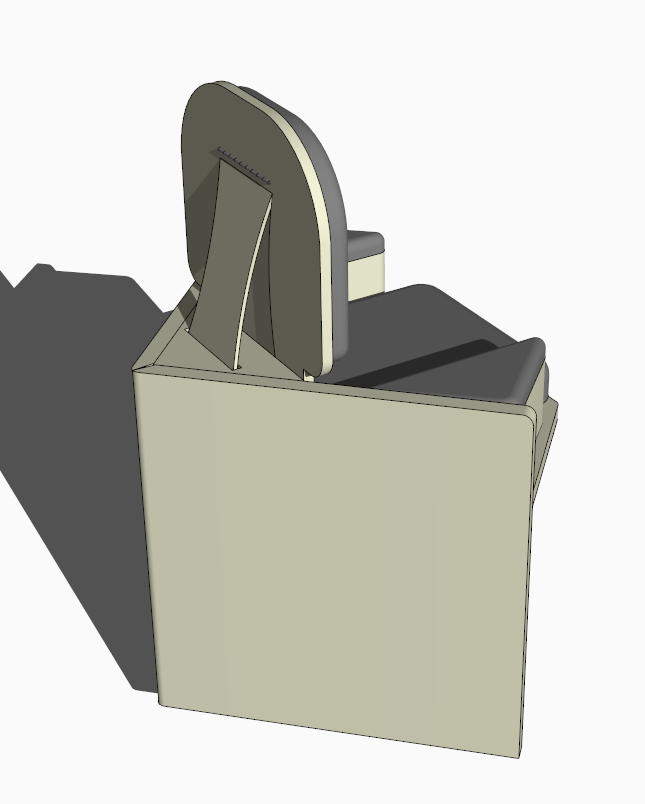

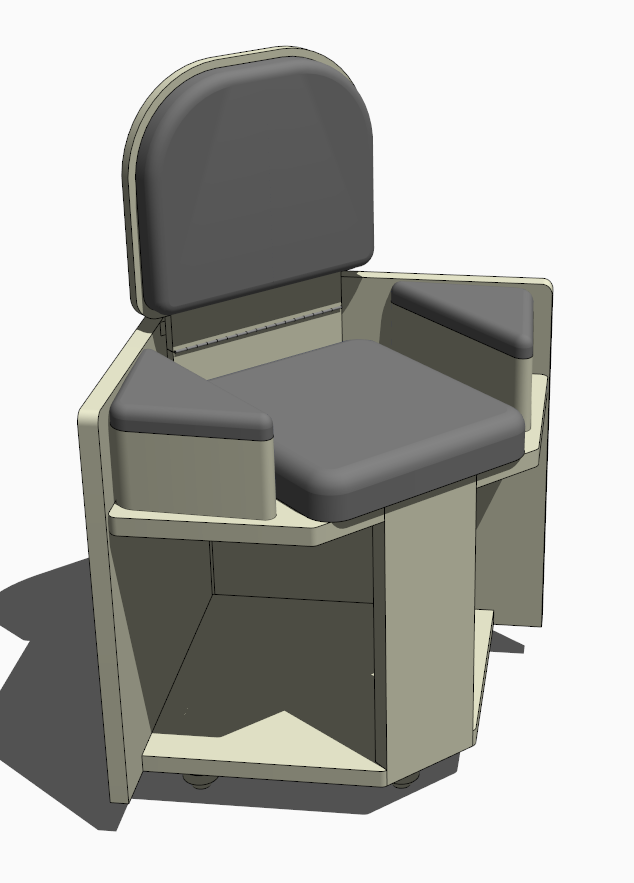

I also figured out a simple way to hold the seat back in the upright position by having a drop down hinged prop.

Non of this is high tech but again I wanted something that could be knocked out in a small workshop.

![Coffee-Dining-Storage (COFFEE POSITION] v3.jpg](/uploads/imported_attachments/4kt9_Coffee-Dining-StorageCOFFEEPOSITIONv3.jpg)

![Coffee-Dining-Storage [DINING POSITION] v3.jpg](/uploads/imported_attachments/8bcs_Coffee-Dining-StorageDININGPOSITIONv3.jpg)

-

Nice idea, but (me being me) I do have one or two observations --

Don't know how much the top might weigh, but seems it might be difficult aligning the dowels into the holes once the top was lifted. You would be unable to actually see the holes because you would be looking down at the table top. Unless you went with your original idea and used a glass tabletop, but then you've got the weight problem again. Also it seems like the dowels would have to be pretty long to provide stability once it's in the raised position, requiring it to be lifted even higher, and they would have to fit very snugly in the holes or the top would wobble. I would also be a bit concerned that this appears to be a two-person operation. Would be much preferable (to me) and more appealing to those that might be interested in your design, to have just one person be able do the transformation from coffee table to dining table, and back again.

Just my thoughts, playing Devil's advocate here

am I becoming a pain yet?

-

Just downloaded your model, and after raising the top noticed that you had tapered the ends of the dowels. This would indeed make the insertion easier. Also noticed after raising it that it might not be as difficult as I first thought to see what you were doing during the operation.

My bad

Really liked the way you designed the hinged props to fold down sideways and the seat back fits neatly around them.

One final question - does the average home workshop have the capability to drill holes that diameter, that deep?

I'm going to bed now

-

Here's a way to make a back-slider.

A groove in the moving part and a HW strip runner on the fixed part with the bottom part half 'bent' inwards as a 'spring-catch'. It then catches when the back is up max, to lower press them in and the back slides down...

-

Yeah, Steve the dowel system is not the best but I think it could be developed. I doubt there would be much stability in what I am showing. Maybe by v10 the best solution might be viable.

Clever system TIG. This again could be further developed.

-

Is it a subject to manufacturing?

Just asking and thinking about the type of material, which has to be used and hold together in any commercial environment.

But, maybe I'm going too far

-

No manufacturing in mind as yet Gregory, just playing around. If it develops into something, so be it

Just thinking out loud ...... maybe TIG's sprung clip could be used in a double central column (inner / outer) to achieve an easy dual height for the table.

-

Maybe...

Make the top [moving] 'sleeve' bigger than the bottom part and use sprung hw catches...

Awkward to 'unlatch' 4 of them !

???

-

How about tabletop supports that move with the tabletop?

-

Yeah, something along the lines of both might work. I was thinking about an umbrella type support struts also.

-

Great idea... though I think as you drew it the 'down' support locations might clash with the chairs under etc...

However, it could be the basis of a neat solution...

Perhaps a two-step lift...

You raise the table higher that its 'up' position and the supports lock in place at their bottom ends, then the top ends of the supports slide out to lock in the top in its 'up'...

Perhaps along these lines ?

-

Think we are getting somewhere now

Probably could do with Dave R for comment as wood can be tricky at times

Probably could do with Dave R for comment as wood can be tricky at times

-

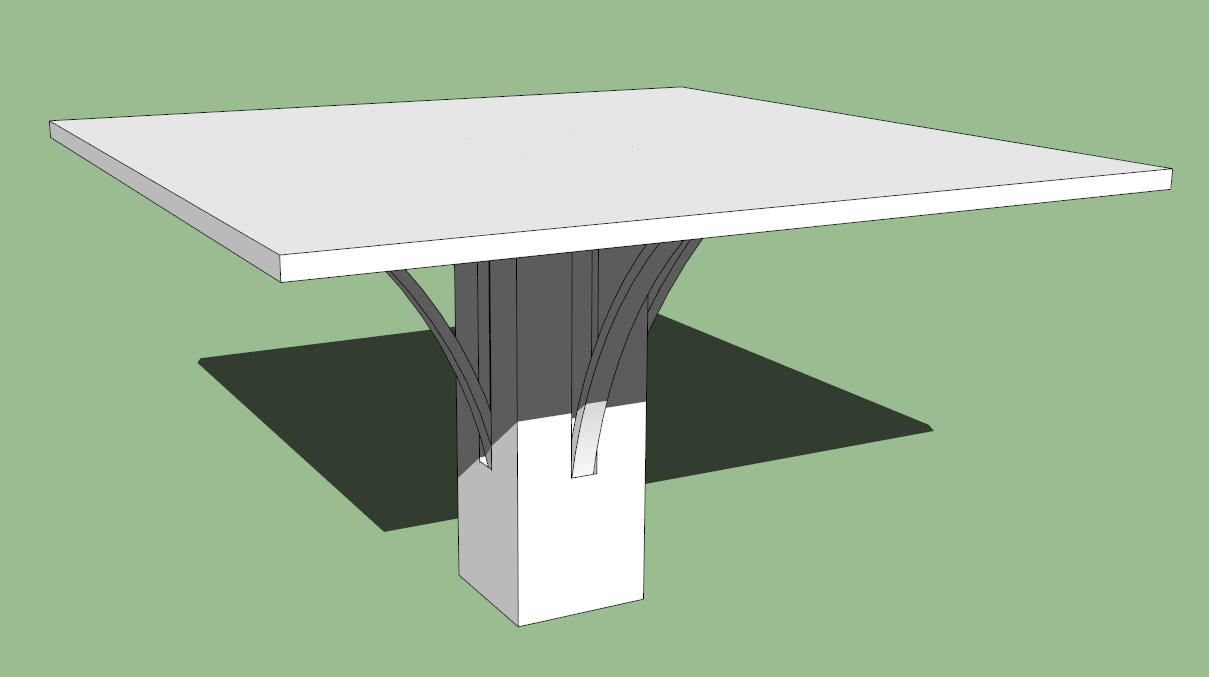

How about simplifying this thing and eliminating the sliding seatback altogether?

Personally I find this version much more inviting and less utilitarian. It has the added benefits of using less material and easier construction.@tig said:

Great idea... though I think as you drew it the 'down' support locations might clash with the chairs under etc...

No, actually they fit quite nicely under there in the lowered position.

This isn't finessed and needs a lot of tweaking but you get the idea

-

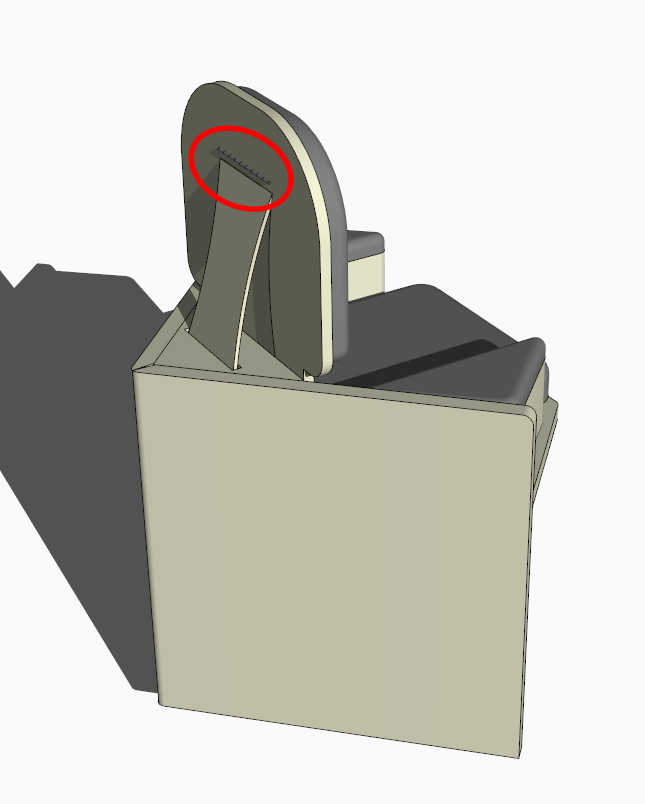

Just noticed that the piano hinge on the back of the chair is not where it should be. I raised it when rotating the seatback support and forgot to lower it again. Sorry about that.

First mistake I've ever made

-

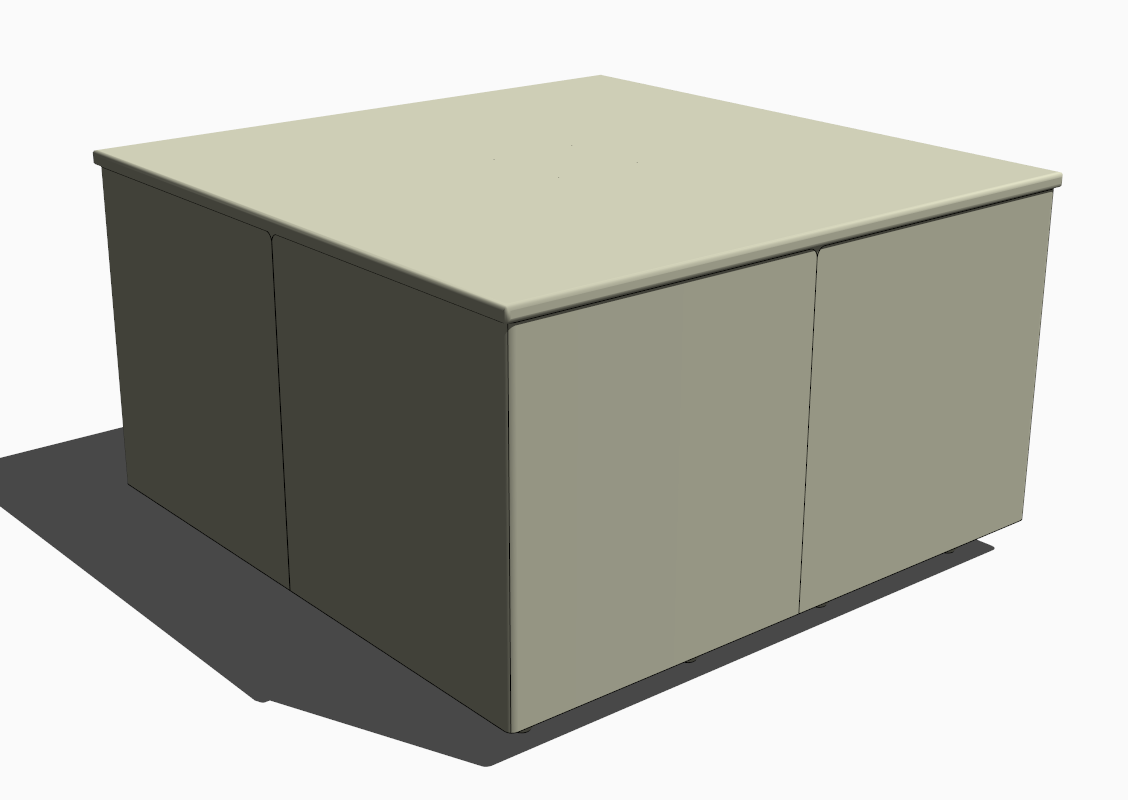

One observation - I don't think any of these ideas would ever qualify as a coffee table. Way too high, and too big too.

-

I have a coffee-table that's bigger in plan, although a few mm lower...

PS: Love the new idea - without the plumbing ! "

-

@tig said:

I have a coffee-table that's bigger in plan, although a few mm lower...

Really? It seems awfully high to me, and it seems like it wouldn't work in the average home, overall size-wise. Only homes with larger than average size living rooms. But whatever, the fun is in the designing.

@tig said:

PS: Love the new idea - without the plumbing ! "

Thanks.

No plumbing??? Would be really convenient. Maybe as an option?

Would be really convenient. Maybe as an option? -

I was also playing around with the idea of a spring in the base to make raising and lowering easier. Any thoughts on this?

-

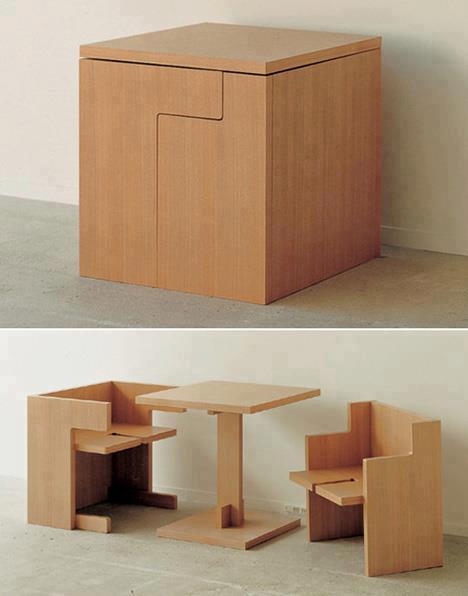

I saw this and thought of you ! Gotta say it's pretty tight.I like the fact it is asymetrical perhaps this is an avenue no one here has been down.

Well Done Stuff

Well Done Stuff. 653,733 likes · 21 talking about this. WellDoneStuff.Com discovers the innovation of human minds across the world. We have made it our...

(www.facebook.com)

PS i don't see it on their main site, anyways both the facebook link and their home page are pretty design centric for us 3D nerds.

Advertisement