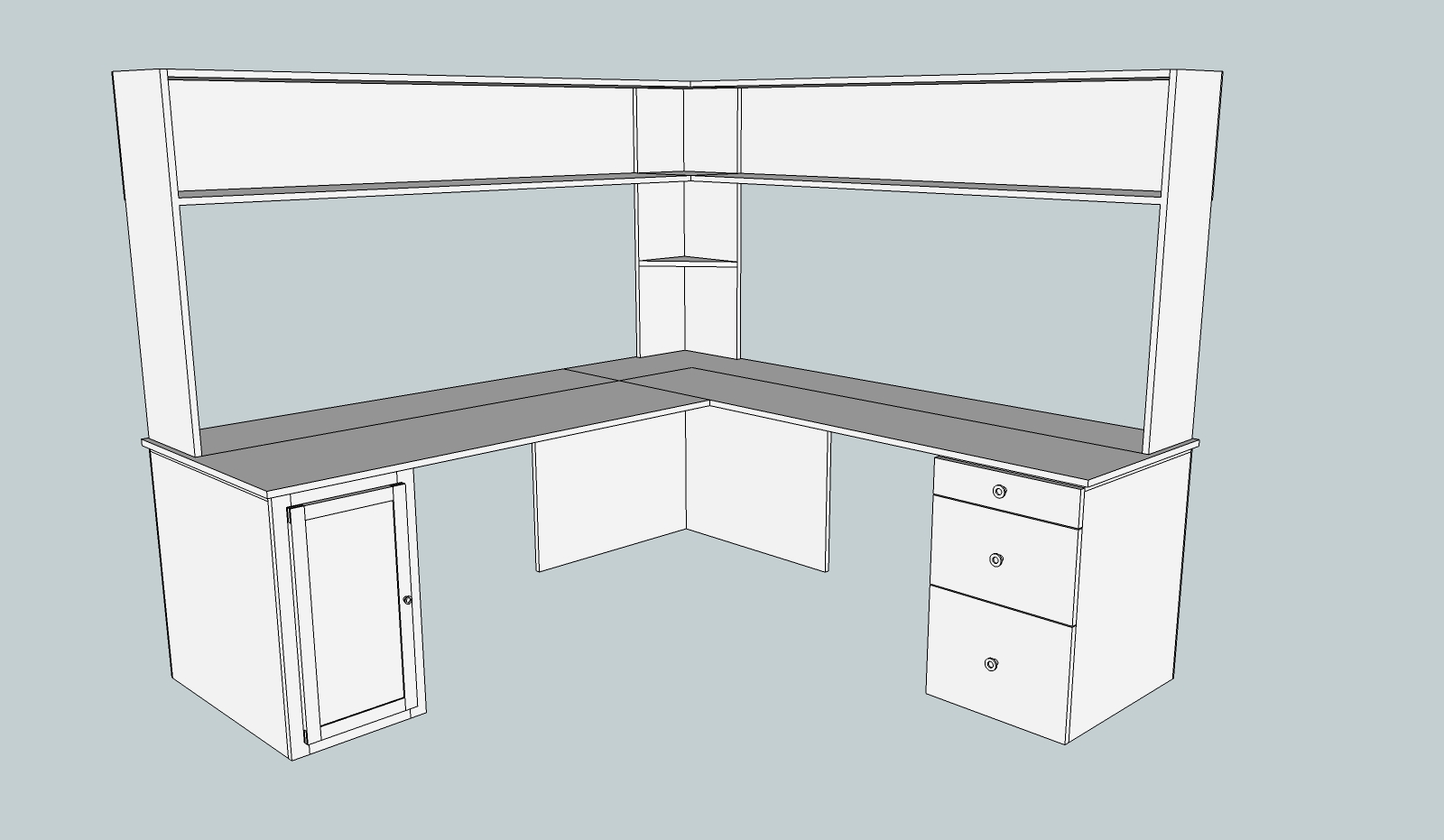

A big frigging L desk

-

I am putting together a man cave / office / gaming room. And I need a desk, a big solid desk. So I started on this monstrosity. Nothing is set in stone.

Some of the proportions are probably off on some of it. Just a rough draft I guess you could say. I will start working on it over the winter months. Probably use solid oak for most of it. Just putting it here to see what some of the woodworkers in here thought.

desk.skp -

It is a big desk. How will you support the top at the corner? I don't think your legs in the back will be enough. I would expect the top to sag and warp unless there's some sort of support at the front. You could do some sort of angled bracket under there so there's clearance for knees.

I would miter the corner joints for the desktop and the shelves above. I was building that desk I'd join those pieces with dominos or a spline to aid in alignment and provide some additional strength.

You didn't ask but it looks as if you could use some assistance with the modeling aspect. I won't go into what I found unless you want me to do so.

-

I am learning as I go Dave. And that is why I posted. To get some more tips, tricks, ideas & thoughts on things I am doing wrong. So go ahead and let her rip. I am saving up some $ for a domino and a bigger planer or drum sander. Probably be a drum sander since my 12"-13" little grizzly planer does mostly all I have ever asked of it. But I have been eyeballing a domino for awhile now.

Thanks Dave I am not sure exactly what all to do with this desk if ya get bored and want to add to it, fix things that would be great. But like I said in my first post this was a rough draft so I was going to keep working it over as time allowed. So go easy on me. -

Cory, here are some suggestions for modeling then.

Use components instead of groups and make components of each piece you would make in the shop. If parts are identical use copies (instances) of the same component rather than drawing each one. Mirrored parts such as left and right case side should be instances of the same component with one flipped (not rotated) to create the mirrored counterpart. Make sure you are only copying components and not the geometry inside them. The rails for the face frame on the left side cabinet are an example of what looks like a case of copying the geometry inside the group instead of copying the group (which should be a component).

Leave all edges and faces on Layer 0 and only put components on other layers. Your cases show that the geometry is on different layers.

You'll like the Domino if you get it. I wish I had room for a drum sander. That would be nice.

-

Thanks again Dave, it will take me a minute to digest, understand & then put that to use. What has happened to me is I have taught myself these bad habits. I will keep working at it and practicing. I am gonna look around at some other L shaped desks and see if I can find some design ideas I can borrow

-

Those bad habits can be difficult to unlearn but it's worthwhile.

I think it's a great idea to look at some already built examples. Good luck.

-

Another suggestion for supporting the corner: Build a pillar that's maybe half the width of the desk tops. It could be square or triangular, mirroring the corner shelves above. If nothing else, the pillar can be a channel for the inevitable clutter of wires and cables for computer, monitor, printer, speakers, and so on. Chances are, your knees won't spend much time under the corner of the desk, so the support there can be pretty substantial.

Good luck with the man-cave and with SketchUp.

dh -

Here is a large L shaped desk I did for our church sec. The panels are oak frames with a 1/2" plywood panel. {I used 1/2 because I could find plain sawed face} The top is particle board with a 1 1/2" solid edge. There is no problem with sagging as I had expected and was ready to add reinforcement.

Keith

-

Quick check of your model shows about 2871 cubic inches for the desk top alone . Oak density is in the range 37-56 lbs/cubic foot. You can do the math. ust that part of the desk will be very heavy( 60 => ~100 lbs). I am a big fan of torsion panels. They are strong, cheap, and light weight. I would recommend you consider that in your design.

Advertisement