:Lancaster Lofts:

-

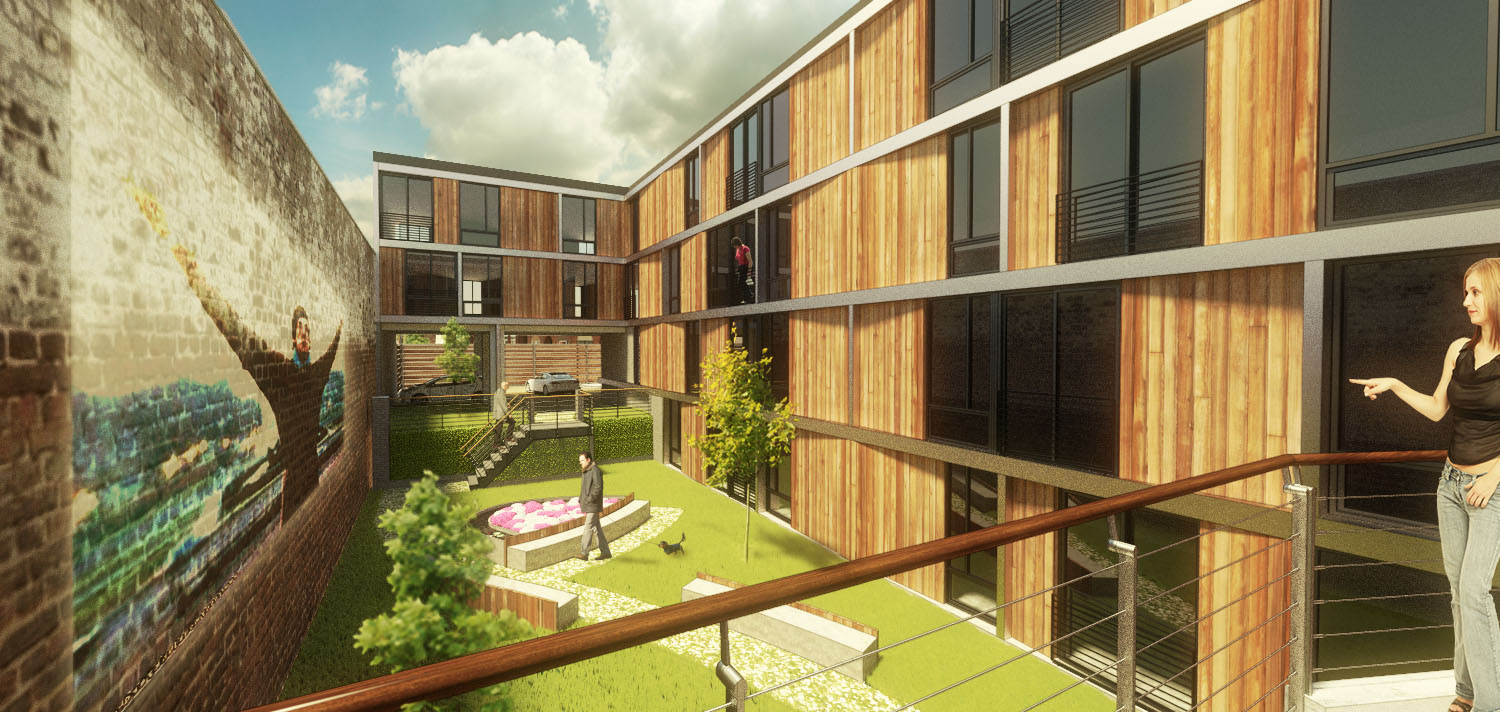

here's an adaptive reuse project i designed last week for an office I work for. its an old industrial building in north philadelphia with an odd bi-level site being renovated into 16 apartments and two small retail spaces. these were semi-quick and conceptual, so there are some minor issues in some of the images... i'm trying to get better with post work

these are done with sketchup/twilight/photoshop

-

Masterful delineation (again). Good to see your new works.

-

I don't normally go for the Modern look... However the use of wood and colors here is really appealing. all of the natural colors soften the scene. really nice. love the front too. whats more the urban area gets a great feel of nature with the inner courtyard. and again those colors tie it all in together. great job...

-

Hello Jason, the "softness" to the first image looks great

-

hi , i like yout post pro of grass , were can u find a picture of a grass please ? thanks

-

Hi Jason,

Love the soft bloom on the images. Nice render and model.

But what is the woman in bikini doing on one of the renders? Don't get me wrong. I think all good renders need at least one good bikini model. But haven't seen many people around here that put this in practice .

.Greetz Twan

-

thanks guys, appreciate it.

ramy.. just do a google search for grass or lawn and a ton of good images will come up to use.

twan.. i should probably ditch the chick in the bikini...but you've got to play to your audience and these clients are old men

-

Jason, inside every old man is a young man saying "WTF happened?"

And my first reaction was YEAAH! Its about time.

-

Looks like this project might actually happen. Slowly getting time to update the model/design.... it gained a floor on the front and I put together a quick image for the lobby.

-

The renders are absolutely amazing Jason!

2 complaints on the design though. The stairs in the courtyard image seem very steep. And the walkway the girl is standing on would NOT work for bare feet. I'm not even sure if it's legal at all! But it is a cool idea.

-

haha.. yeah, agreed on both. those were quick and conceptual. the stairs were stretched and fudged into place in a rush and the grating is definitely gone now.

-

here are the updates to the interior courtyard and rear. it remained pretty true to concept. the window placements aren't ideal but they're not based on the unit layouts; the angles of the faceted facade aren't quite as steep unfortunately; and the whole thing flipped to take advantage of an adjacent party wall.

-

Great updates.

-

Thanks Bryan.

-

the inner courtyard of this lost its sawtooth pattern and the front facade couldnt be salvaged, but its more or less intact and construction has started..

-

Nice mate, great project!!!!!!!!!

Wondering though about the process there during construction, it looks as though the whole wall is first clad in ply and then the opening cut out? Is this right?

-

Yeah that's how they're doing it...moves along much quicker. Cut it out from the inside after the fact.

-

Wow! Seems like MASSIVE waste, everything here these days is about waste saving! I know plywood has a tonne of reuse options, but still!

-

What's the other option? Even if you cut it beforehand, you're cutting out the same amount. Otherwise, you'd end up with a bunch of small pieces all over and that can't be good for shear strength.

-

@marked001 said:

What's the other option? Even if you cut it beforehand, you're cutting out the same amount. Otherwise, you'd end up with a bunch of small pieces all over and that can't be good for shear strength.

Mate we tend to design it in! Making sure all panels / windows and opening work at 300mm grids - then the use of a 2400mm or 2700mm sheet can be cut to 600/900/1200/1500/1800/2100 and then the offcut of any sheet has a re positioning option within the wall.

I'm just doing this exercise now on a house design where everything works in off shelf SIP panels @ 900 or 1200 wide x 2400/2700/3000 high - then ply linings at 900 wide x 2400 high and built in joinery at 600 and 900 - the total waste will fill a wheel burrow and virtually no onsite cutting.

We look at:

The cost of excess material, all all reasons of environment, transport and budget.

Any waste if it cant be stored, the cost of disposal,

Speed of building.

The embodied energy in that waste.It also helps too if any post completion off cuts are of these multiple sizes as if they can be stored they will have a purpose later!

Advertisement