Hello, and a *huge* problem with hidden faces.

-

@teto42740 said:

Someone in another forum told me that the way how the datas are stored is a pure mess and other softs like Blender "don't understand what's going on".

Are you sure that "someone" knew what he was saying? And not only wanted to put SU down because he does not understand it or because of snobbery?

We've seen a lot of occasions like that.

-

I don't know. But for the moment nobody was able to explain me how to do. And the guy told me that he spent almost a day to try having a good conversion, without success. I googled that problem and found nothing.

So...

Everybody here is working with sketchup, and only with sketchup. An example, why are there renderers especially made for Sketchup ? Why other modelers don't read natively sketchup files ?

Maybe I'm wrong, but if after 2 weeks I don't have a solution about a problem, it's because there a big problem. If someone can show me how to export sketchup files (that I can modify after), be my guest !

Many thanks for you help anyway, again.

-

@teto42740 said:

I don't know. But for the moment nobody was able to explain me how to do. And the guy told me that he spent almost a day to try having a good conversion, without success. I googled that problem and found nothing.

Well, if he tried unsuccessfully to convert your model I believe he had some problems. It's full of problems and modeling errors.

First of all, everything is modeled backwards, ie all the faces are flipped so that the backfaces points forward.

In my second Modeler/renderer, LightWave3D, they will be invisible by default, unless I tell them to be double-sided.

It's a good rule to always model with frontface faing outwards.

Second, your model is made from a mix of groups and freestanding lines/faces. That is not at all a good way to model in SketchUp. And it is way to complicated/detailed with lots of errors and unnecessary edges/faces.

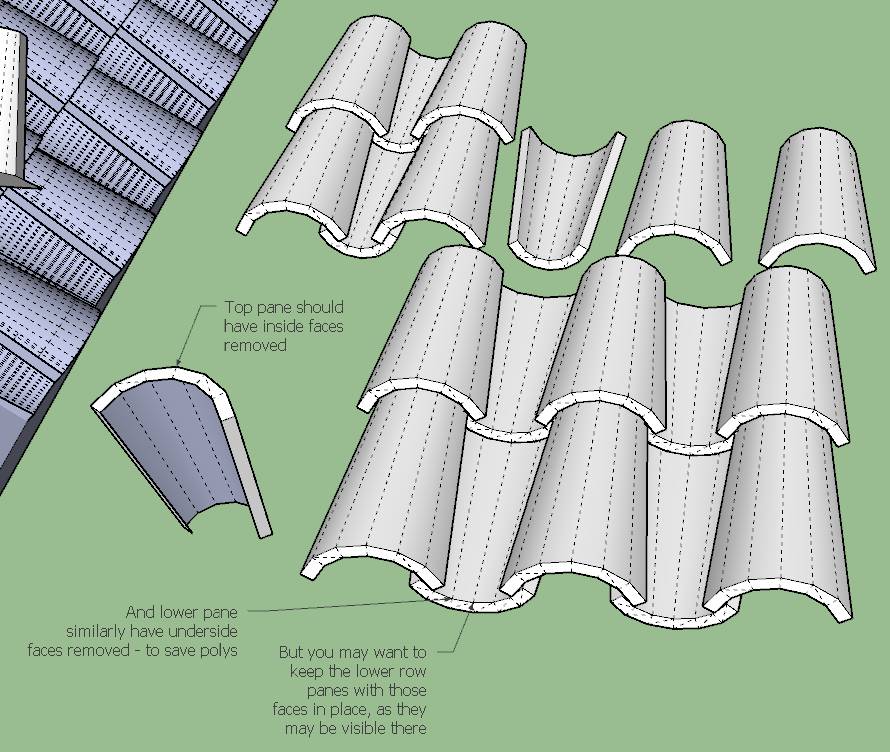

You should have modeled one pane as a component, complete with all the details, thickness etc.

Or made two different, one top/convex and one bottom/concave.

Then you could just Move/copy hundreds of them. When you want LOD you just edit/simplify one component and all the panes are changed at the same time.

Another problem is that you have given the material/color to the Layer instead of to the faces. I don't think that will export well.@unknownuser said:

So...

Everybody here is working with sketchup, and only with sketchup. An example, why are there renderers especially made for Sketchup ? Why other modelers don't read natively sketchup files ?

I don't know why you assume we all work with only SketchUp? I have used at least 10 different 3D programs, and now I use mainly SketchUp and LightWave, because it causes the least problems and best results

I'm sure a lot of the SU users are using other programs as well.

And several programs can now read skp files.@unknownuser said:

Maybe I'm wrong, but if after 2 weeks I don't have a solution about a problem, it's because there a big problem. If someone can show me how to export sketchup files (that I can modify after), be my guest !

Many thanks for you help anyway, again.

So if you can't find a solution in 2 weeks you blame it on the software and not yourself?

Strange!

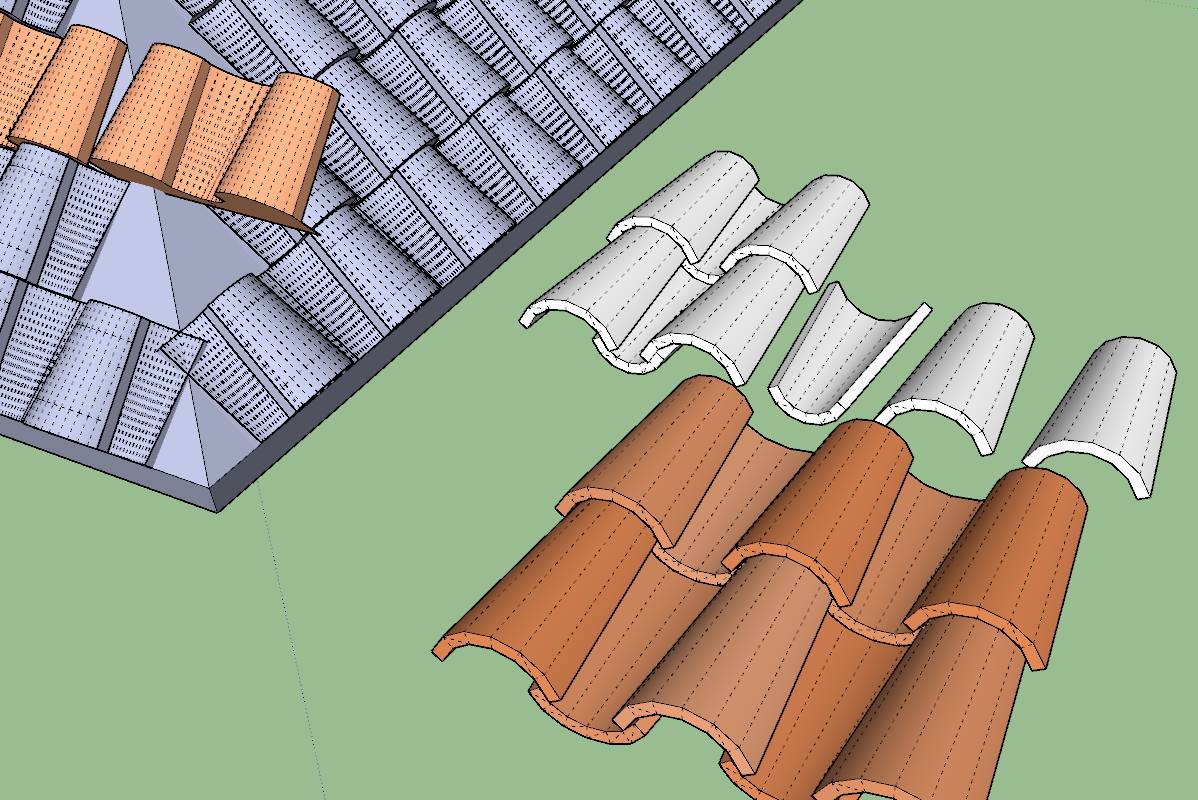

Yes, there is a big problem here, but I'm afraid that that is not because of shortcomings of the software, but more of an attitude problem?BTW, here's a couple of very quick examples.

-

teto42740

Couple fact toids for you:

Blender had a plugin that imported SU and then one of the later revs ( 2.5??) they tried to make SU import to Blender native and created a bug. I and several others wrote a bug report, its been some time ago , so don't know if it is fixed yet;

In your original model the basic cover tile ( had no pan at that time) was a solid but when you encapsulated that item it then reported as non solid. So you could have used the outer shell approach to make the classic pan / cover combo show a above and it would be " water tight". You would then what to make that a component. Then after converting all the groups you have in the original model to components you could replace with that combo. I have not done that yet. The concern of course is to not get in a mode where a bunch of those would have to be unique

Your original model has some 198k+ edges that can be decimated to a much lower value ( MeshLab comes to mind) but getting the model correct form the start will help in the long run.

Good luck you way very well be back. -

@bjornkn said:

Well, if he tried unsuccessfully to convert your model I believe he had some problems. It's full of problems and modeling errors.

First of all, everything is modeled backwards, ie all the faces are flipped so that the backfaces points forward....

It's a good rule to always model with frontface faing outwards.

My bad!

I was pretty sure that the faces had a good orientation. I was aware about this, and was sure that my model was modeled forward. :facepalm:

I was pretty sure that the faces had a good orientation. I was aware about this, and was sure that my model was modeled forward. :facepalm:@bjornkn said:

Second, your model is made from a mix of groups and freestanding lines/faces. That is not at all a good way to model in SketchUp. And it is way to complicated/detailed with lots of errors and unnecessary edges/faces.

You should have modeled one pane as a component, complete with all the details, thickness etc.

Or made two different, one top/convex and one bottom/concave.If you open my first model, you should see that my first test was made as you said, basically (except that it is modeled backwards, of course).

@bjornkn said:

I don't know why you assume we all work with only SketchUp? I have used at least 10 different 3D programs, and now I use mainly SketchUp and LightWave, because it causes the least problems and best results

I'm sure a lot of the SU users are using other programs as well.

And several programs can now read skp files.Pleased to hear that. But as nobody answered me about that for few days, I assumed what I wrote. My bad, again.

@bjornkn said:

So if you can't find a solution in 2 weeks you blame it on the software and not yourself?

Strange!

Yes, there is a big problem here, but I'm afraid that that is not because of shortcomings of the software, but more of an attitude problem?If you posted just for these lines, and the fact that you have skill (with image and no explication), well, keep you lines, and your skill. I may want your help, not your skill. Thanks.

I note that you didn't post until I wrote "Sketchup sucks!". Strange.@mac1 : Thanks, you were very helpful.

Anyway, I'll test few things with BASIC shapes (cubes...) and try union, decimate, and so on, under Blender. If it works, I will be pleased to continue on Sketchup, really. Thanks everybody for you time, I appreciate.

-

teto42740

Here is the first step using ideas I discussed before. http://sketchup.google.com/3dwarehouse/details?mid=5763d41196ce8b4048da91396cd7935f

What I did was exploded portions of your fist model to get to the basic tile which was solid. I created two then to make an s tile component. At this step you could " merge the two ( like in your second model) and use the shell tool to make what I think you want. I then converted all the tile groups you had to components ( use plugin for that), used the outliner to select all those and then in the component browser selected the s tile and did a replace selected to get to the model shown here. The coin is assigned a layer so turn those off and you will see areas needing some work. I would probably make those over lap components unique, trim to fit ,but since I almost never complete a model for someone learning finishing is up to you if desired.

Good Luck -

@teto42740 said:

If you posted just for these lines, and the fact that you have skill (with image and no explication), well, keep you lines, and your skill. I may want your help, not your skill. Thanks.

I note that you didn't post until I wrote "Sketchup sucks!". Strange.Well, if you look back 3 days ago I posted some tips about merging points and solids/meshes etc.

Didn't download any files until today though.

If you read my last post again you'll find lots of explanations on how I would approach modeling such a roof, using components etc. I don't think the modeling of such simple pans should need any further explanations?

-

And if you read back further you will see comments about the OP approach. As usual there are more than one way to do models in SU and info to OP should not be filtered by one view point.

-

tet42740

Some additional info for you:

I used MeshLab and and did a quadratic edge collapse decimation and was able to reduces the edges in the model by ~200,000. However Meshlab is not easy to use and looking at the model more it became apparent the basic tile model has some problems. There are a number of edges which IMO should not be there. There are some specific mathmatical relations required if you attempt to model it using the ARC tool and very small errors can cause the problems you see in that model.

If you want to correct ,create a cylinder( The OD I measured was 96.453 mm, make it just a zero thickness ( no wall thickness) I'll explain why below, extrude it up to the 250mm ht, select the top and scale down by the ratio to get the small dia you want ( I measuerd 71.190 mm for that). You can then go ahead and use the off set tool to set the 15mm thickness. The reason for waiting to this step is the scale tool will scale the thickness if you do it early. I then used the section tool to cut the truncated cylinder at one of the edges lines, make the section a group , intersect with model and delete the undesired portion. When I replaced this new tile with the ones in my posted model, which was based on what was in your orginial OP, the number of model edges reduced >= 200,000.

Just some thoughts for you

-

@mac1 said:

tet42740

Some additional info for you:

I used MeshLab and and did a quadratic edge collapse decimation and was able to reduces the edges in the model by ~200,000. However Meshlab is not easy to use and looking at the model more it became apparent the basic tile model has some problems. There are a number of edges which IMO should not be there. There are some specific mathmatical relations required if you attempt to model it using the ARC tool and very small errors can cause the problems you see in that model.

If you want to correct ,create a cylinder( The OD I measured was 96.453 mm, make it just a zero thickness ( no wall thickness) I'll explain why below, extrude it up to the 250mm ht, select the top and scale down by the ratio to get the small dia you want ( I measuerd 71.190 mm for that). You can then go ahead and use the off set tool to set the 15mm thickness. The reason for waiting to this step is the scale tool will scale the thickness if you do it early. I then used the section tool to cut the truncated cylinder at one of the edges lines, make the section a group , intersect with model and delete the undesired portion. When I replaced this new tile with the ones in my posted model, which was based on what was in your orginial OP, the number of model edges reduced >= 200,000.

Just some thoughts for you

Sorry, I was... delayed. :gandalf:

Thanks a lot, I clearly understood. I must change the way I work. I've used many industrial modelers for my job (Catia, Euclid, ... : oldies : ) and it's no good with softs like Sketchup or Blender.Cheers.

Advertisement