Question regarding push-pull tool

-

hi guys,

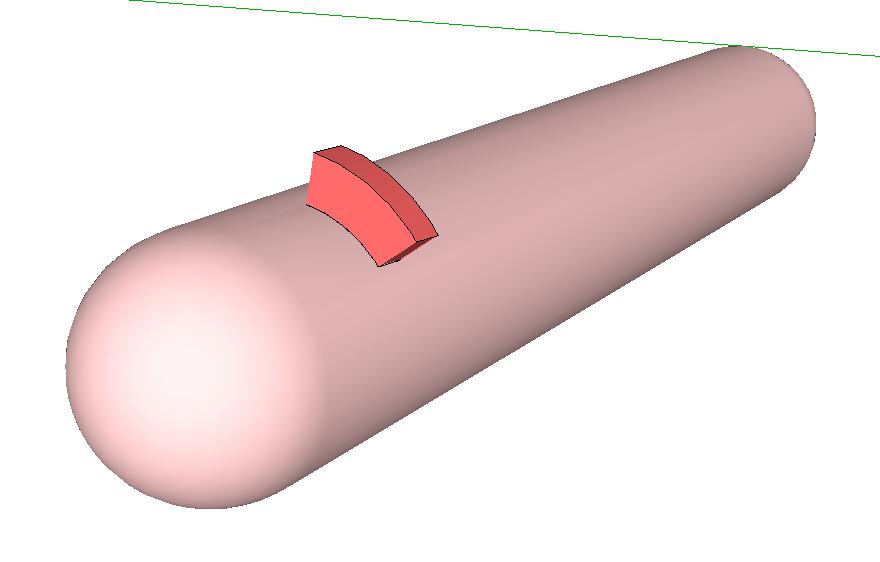

i would like to know how can i push-pull inward a surface on a cylinder. i tried the joint push pull but the surface I selected is been pushed outward, i want it to be inward as you can see from the picture, i want the surface to be "inside" the rod.

thanks!

-

haha guys, sorry, i should do a search on google before i post any question next time.

it's easy to do inward pushed surface, just type in negative distance value.

-

I would like to know HOW you got the push/pull tool to work on a curved surface?

In either direction.

-

I think he was referring to Fredo´s Joint Push Pull.

-

@numbthumb said:

I think he was referring to Fredo´s Joint Push Pull.

Many thanks for the reference.

Using SU for 3 years now and this is the first I've heard of Fredos JPP.

So I just looked up that thread, and downloaded the files. Won't have time to try it for a while as I work for Elections Canada and an election was just called today. There goes all my free time between 8:30am and 9:30pm till 4 May.

Anyway, my best use of such a tool would be when I draw airplane skin parts. I normally draw to the moldline, then as almost all my designs use a 1/2 inch thick (or so) composite aeroshell, I copy the surface (inward) 1/2 inch then scale it to almost match the outer curve. My biggest problem is where the shell tapers at nose and tail. I cannot control the thickness ratio change using scale, which entails a lot of manual adjustment, let alone facing the edges, one line at a time.

I just hope the JPP "thickening" function will do that job for me.

-

You might find Simple Shell useful.

http://forums.sketchucation.com/viewtopic.php?t=33169 -

Simple shell works with the scaling method so Joel's issues with the tapered part would still remain.

JPP is not "perfect" either with too complex forms but mayyield better results with aeroplane hulls.

-

@gaieus said:

Simple shell works with the scaling method so Joel's issues with the tapered part would still remain.

JPP is not "perfect" either with too complex forms but mayyield better results with aeroplane hulls.

Now you really have me curious.

-

Well I found some (little) time to play a bit with JPP and ........

After about 10 minutes playing with JPP, I did a simulated fuselage nose skin section, and then pulled the outer surface in an inch (thicken) in under 10 seconds. Took me over an hour to do that before using the copy, scale in 3 axis, join the edges, then tweak it into shape. Sticking a door into the fuselage (which is 3 inches thick with a window) took a minute to draw it in and 15 seconds to make the door group, versus over an hour before to get that same shape, but with many minor errors.

This has got to be one of the 10 all time best plug-ins for SU, and really should be an integral part of the next SU version release.

Now I gotta spend some time with it, and tweak some defaults as described in the thread and documentation, which incidentally is also the best written for a plug-in I've seen yet.

Now my biggest problem is whether I go back and redo many of my airplane models and rid them of my manual error ridden thick panels. In one major case that's a 90% redraw, but probably worth it.

Fredo.... THANK YOU THANK YOU THANK YOU

Advertisement