2D curve wrap to surface cylinder-best method?

-

Experienced user --- SU Pro 7.0 --getting up to speed with plug-ins.

We do traditional circular stair work, and need to vary pitch of curved stringers. No problem developing simple spirals. I believe the strategy for stringers (whose sides are cylindric surfaces) is best done by plotting the path on surface of a cylinder and, drawing it forward with the "joint push/pull" plug-in, resulting in a 3D stringer.

Handrails are best made with an extrude along path plug-in, but the same tool does not create correct stringer geometry. Especially when pitch of stringer changes.

I'd appreciate suggestions for strategies and apps to accomplish the above.

Also suggestions for the best way to wrap a 2D generated curve on to ylindric surface.I've attempted to use the "unfold" plug-in, but have no luck with it at all.

If this is not best location for this post, please let me know.

-

I would use fredo's surface tools plugin.

It lets you draw any shape onto a surface.

its probably the easiest way to go.

the link is here

http://forums.sketchucation.com/viewtopic.php?f=180&t=11212Hope it helps!

Taylor -

I thought the surface tools would be the answer but I had no luck with them. It's possible I'm trying to apply curves to too small(tight) a cylinder. The curves would remain crazily out in space.

-

I believe this may help http://forums.sketchucation.com/viewtopic.php?p=237755#p237755

Also the plugin 1001 bitpro http://www.1001bit.com/pro/ I believe has circular stair capabilities in it's stair tool, although I haven't used it yet.Cheers

-

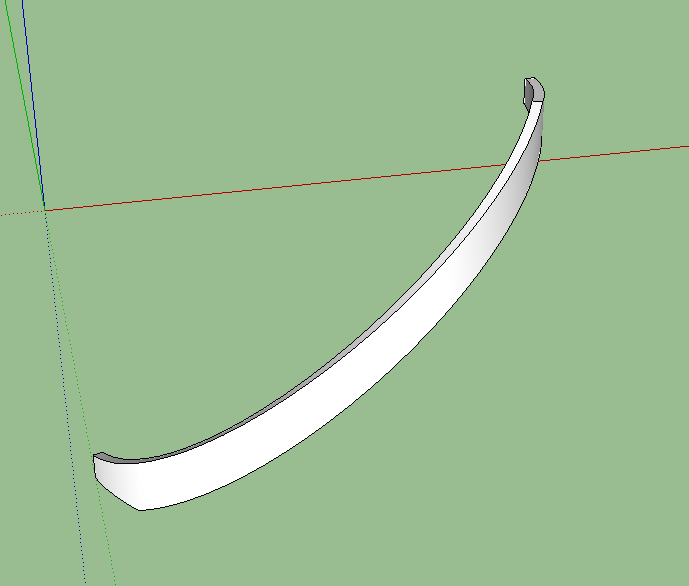

you might want to look at ShapeBender by Chris Fullmer:

http://forums.sketchucation.com/viewtopic.php?t=18210or FredoScale by Fredo6 (which has a radial bending function)

http://forums.sketchucation.com/viewtopic.php?t=17948[though i admit, i'm not 100% sure about what you're trying to accomplish.. a sample .skp attached to your post could help clarify your question a bit]

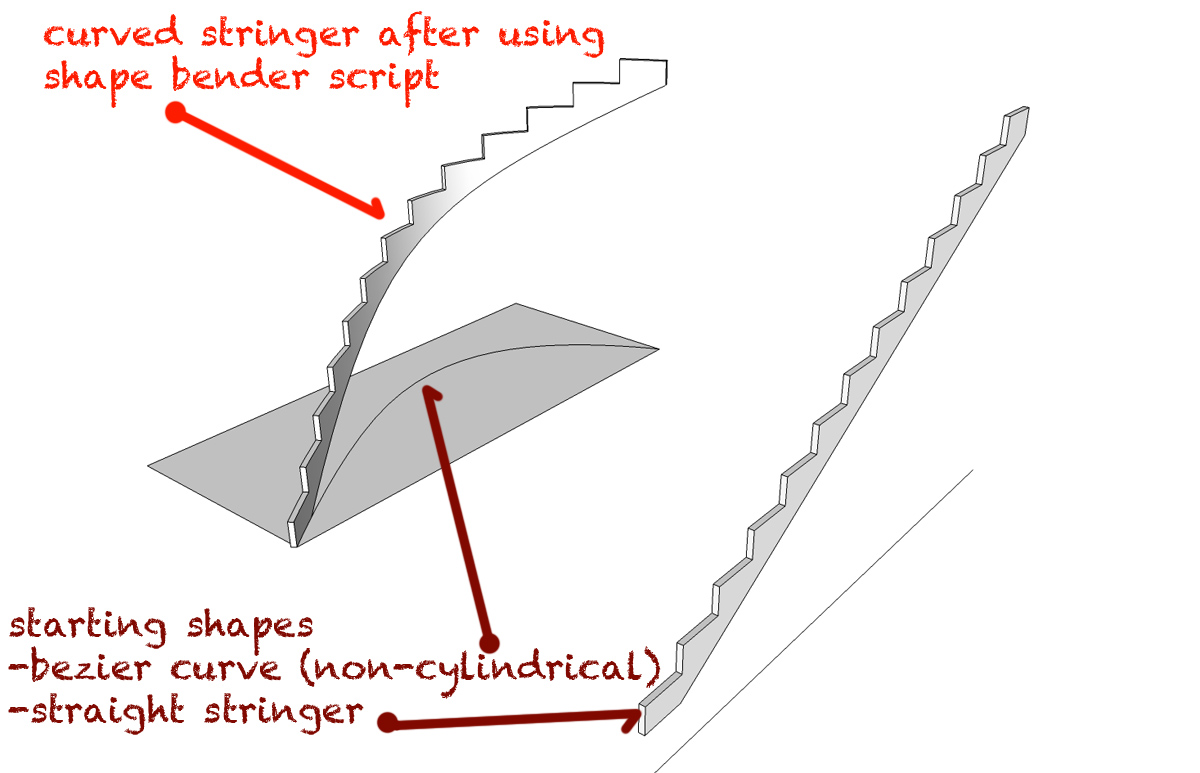

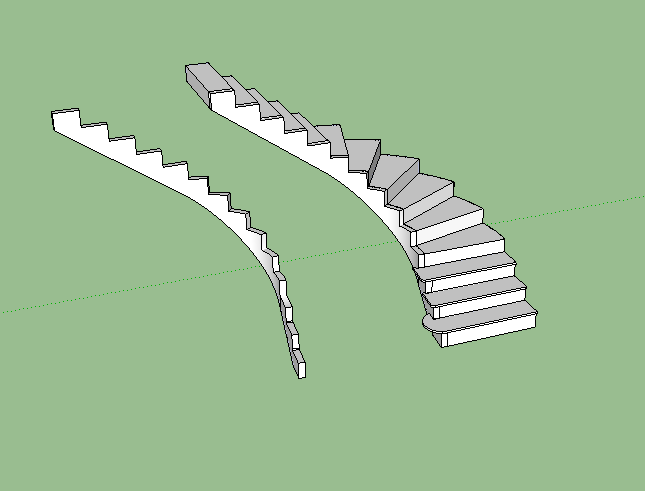

here's an example of using shape bender to generate a 3d stringer following a non-radius curve:

-

Jeff,

The shape bender looks like it may be very useful. ie. the best route. I have the Fredoscale, but haven't found the key to making that tool give me desired results.

-

Then again ---got shape to work once -----then no deal.

compared to the complexity of follow or extraude along path this should be pretty basic.

It is the application of wrapping a 2D spline or arc curve to a cylinder. That gives me a reliable work path.

I'd finally hoped i'd gotten to a reliable method of creating 3D's of this stuff.

Pretty frustrating.

-

Like I said, im not really sure what you're trying to draw. Are you just trying to make a helix around a cylinder? If so, there are a few easy ways to go about doing that.

-

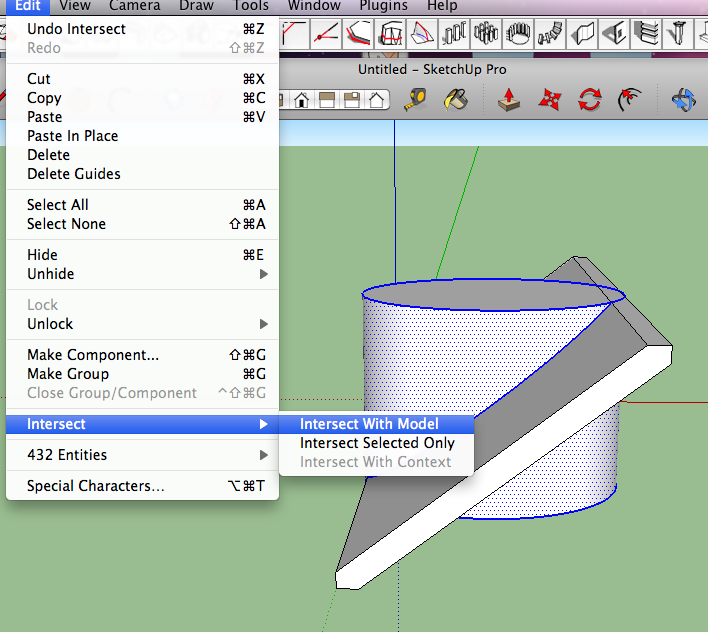

So correct me if I'm wrong but. If we have a set of stairs that has a full rise of say 108", and we want 14 rises it would calculate out yo 7.714". If we decide on a 10" run, then the angle can be calculated to 37.6 degrees.

If we were to draw this stringer out, push pull it through the proper radius of cylinder, and intersect with model(cylinder) would it not project the correct stringer on to the cylinder? Which could be Joint pushpulled to width.

-

Simple helix is not a problem. The issue is creating transitions between helixes of different pitches.

Think of a handrail on a circular stair that does a graceful transition either to level or to a section of the stair that is not pitched the same. The top of the stringer below is usually similarly configured.

Most stair models I've seen here are simple spirals. While portions of some of our circular stairs can be developed as simple spirals, most are more complex and have been very difficult to draw in SU

Attached is a photo/example of one such of transition.

-

Dale,

Sorry, but your example doesn't work really. the stringer generated is narrow in the middle and wide (taller) at the top and and ---well, there are a bunch of other issues.I actually use the geometry of cylindric sections often in my work, but re. SU and what I'm trying to accomplish with it,---that's not the answer.

-

@dale said:

If we decide on a 10" run, then the angle can be calculated to 37.6 degrees.

thing is, if you intersect a plane with a cylinder as you've shown, the only place that angle will actually be 37.6 degrees is exactly at the point of perpendicular contact (on a radius line of the cylinder).. everywhere else on the cylinder, the angle will change..

this skp might show the problem better than i can explain with words.

.

-

@volutes54 said:

Simple helix is not a problem. The issue is creating transitions between helixes of different pitches.

that picture helps but just to be clear, when you say 'helixes of different pitches', are you meaning the radius (top view radius) changes..

when i read pitches earlier, i thought you were talking about changes in steepness (as in roof pitches) which was(is) confusing..

i don't think you're building stairs that have a 7" rise for a little bit then they switch to 9", right? -

Of course,

Thanks.

Thanks.

Are we actually talking about an elliptical helix? -

Actually the pitch may change because there is a transition from straight treads to winders, which shortens the run of the tread relative to the rise (which does stay constant).

And some stairs are nominally "elliptical" in that while their plan may not be described as a true ellipse, one portion will have a broad radius and other sections will have a tight radius.

Jeff, there are many "elliptical" plan stairs in those old Manhattan and Brooklyn brownstones in your area.

The stringer of the stair shown in the accompanying photos varies in pitch and plan radius. The upper treads are straight and have three baluster. The lower treads are two baluster per--, and the lower end at handrail volute tightens into shorter radius. Yes the upper portion of the stringer is straight in plan, but a smooth transition was made into the steeper curved section. The second photo illustrates the sort of curve that might be developed on a cylindric surface.

-

and another view from the side

-

@volutes54 said:

Actually the pitch may change because there is a transition from straight treads to winders, which shortens the run of the tread relative to the rise (which does stay constant).

And some stairs are nominally "elliptical" in that while their plan may not be described as a true ellipse, one portion will have a broad radius and other sections will have a tight radius.

Jeff, there are many "elliptical" plan stairs in those old Manhattan and Brooklyn brownstones in your area.

The stringer of the stair shown in the accompanying photos varies in pitch and plan radius. The upper treads are straight and have three baluster. The lower treads are two baluster per--, and the lower end at handrail volute tightens into shorter radius. Yes the upper portion of the stringer is straight in plan, but a smooth transition was made into the steeper curved section. The second photo illustrates the sort of curve that might be developed on a cylindric surface.i'm on the top floor of my brownstone (in brooklyn) and have 2 really sweet 100+yr old staircases to navigate every day..

(probably very similar to what you're trying to draw)

(probably very similar to what you're trying to draw)and now that i think of it, a spiral staircase can change pitch simply depending on if you're walking up the inner or outer edge of the thing.

i've gotta get ready to go out but i'll post back later with some ideas.

-

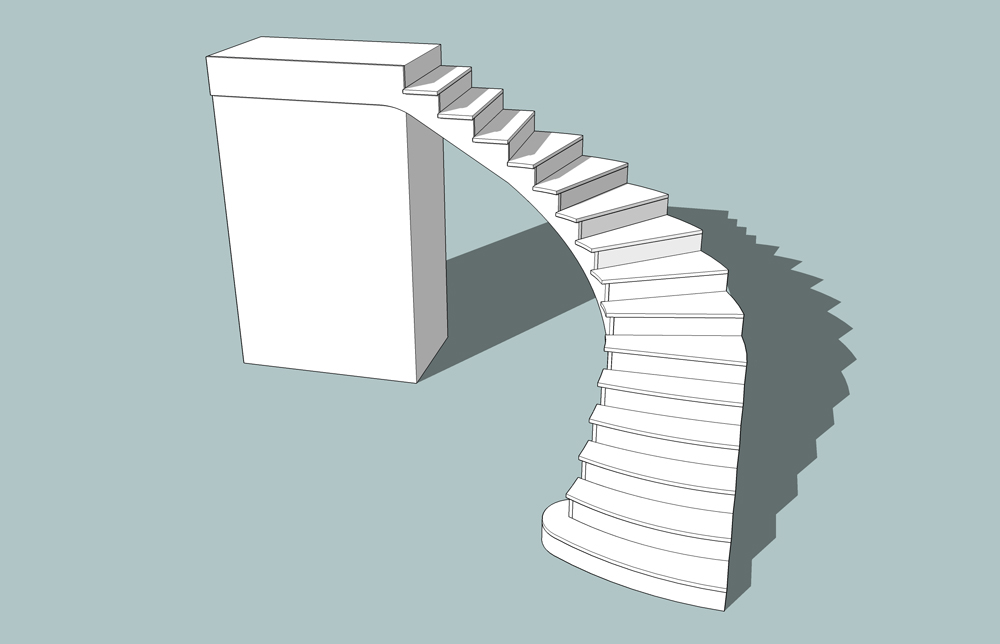

i took a stab at drawing the stairs in your pictures.. i stopped before getting too detailed (no risers, routed edges, railings etc.) but i'm wondering if anything in the drawing is what you're trying to do? if so, i can show you what i did for that part (and actually, once i nearly finished this, i thought up a different method that i could probably do a lot quicker)

i just guessed at the dimensions and tried to get as close to what's happening in the picture as i could see but i think another angle or two would help.. if these are drawn more or less to the proper shape then i would forget about a plugin for drawing a lot of it.. there's just too many weird little things happening in there for a plugin (i think?)i used mostly the line tool and other vanilla sketchup tools for this. (no cylinders though)..

plugins used were:

select curve

weld

extrude edge by vector (this is one that i'm sure you'll find a use for)

a little bit of extrude edges by rails for the bottom of the stringeranyway, i may have found a way to draw them a bit faster but not by much.. (unless it takes you 2+ hrs to draw this much.. then i found a time saver for you)

-

Jeff,

Excellent! The element that I've had trouble with is the stringer ---ie. the side of the stair below the inside radius tread ends. I need to upgrade my SU to v.8 in order examine your model more closely. I'll do that later this today.

-

Like Jeff I couldn't leave this alone,so also tried to replicate from the photo.

The problems I had were similar to ones you mentioned earlier in the Tools on Surface just wanted to make these random lines that seemed to go to some theoretical centre.

When I am doing designs for guitars I have to scale up in order to do some of the work on the neck as it seems to want to leave out some of the triangulation, so you don't get a selectable face. That's what I did here although I still had one line I could not erase without deleting part of the face. I scaled up by a factor of 10, but I think going even bigger would be better.

Used TOS, and Joint Pushpull.

By the way, visited your website, you do some very fine work.

Cheers

Advertisement