Dimension what can be measured at least

-

If the tape can measure it, SU should be willing to dimension it, for free.

-

What is it that can be measuerd but not dimensioned?

-

When using the tape (measure) tool, ordinary SU snaps and inferences are active and helpful and they can be forced with the arrow or shift keys. These seem to be very limited in dimensioning.

-

If you have a sheet of steel with some holes punched in it and you want to show the dimension from the center of a hole to the edge of the steel, you can't. If you start from the edge, it just gives the dimension of the edge itself. If you start from the center of the hole then it won't snap to the edge of the steel. What you have to do is to draw a line from the center of the hole to the edge, then draw another line off at an angle, then delete the first line (which is in two pieces since it crosses another line where it crosses the outside radius of the hole), the snap the dimenion from the center of the hole to the base of the angled line (which is on the edge of the piece), then you can go and delete the angled line.

So frustrating and time consuming.

Also, the way you can move a dimension or text tag around but you can't choose what side it's on. For instance, if you have a long tag, you might want to make the line coming back under the tag like a sideways V with one leg as the tag and the other leg going to the point, but you can't. If you pull the arrow away, then the tag goes even farther away like a big tilde ~.

-

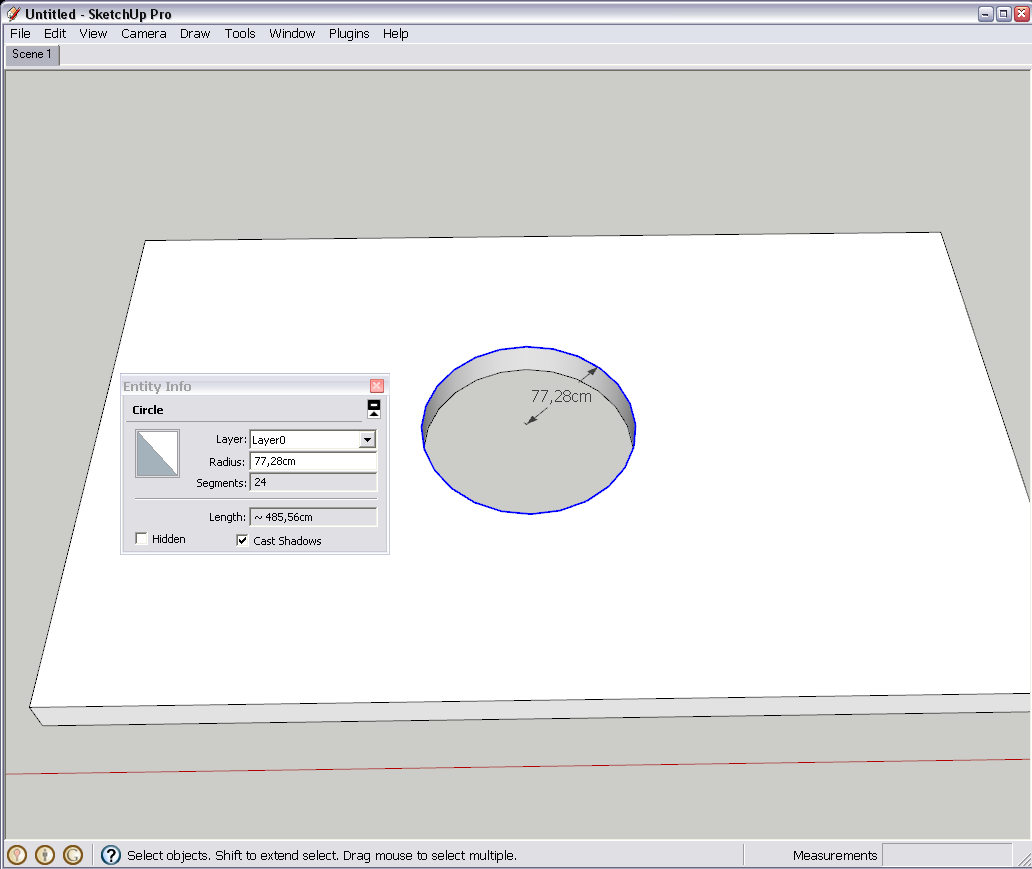

Well, I don't know but I can dimension a radius starting from the centerpoint to the perimeter of the circle of a punched hole:

-

@gaieus said:

Well, I don't know but I can dimension a radius starting from the centerpoint to the perimeter of the circle of a punched hole:

@banaticus said:

If you have a sheet of steel with some holes punched in it and you want to show the dimension from the center of a hole to the edge of the steel...

Not to the edge of the hole, to the edge of the steel plate. For instance, dimensioning from the middle of these holes to the edges of the U-bracket, because when you're laying something out you measure from the edge to the center of the hole that you're about to drill. I usually use diameter instead of radius because drill bits are listed by diameter.

Yes, that top left corner is busy (and the 1 1/2 should possibly be to the right in line with the 3" measurements), but that's the way they wanted it and of course I want whatever they want.

As far as dimensioning goes, I really wish that I could choose both the rotation of the diameter line and the placement of the text, but the placement of the text automatically forces a particular orientation of the diameter arrows.

As far as dimensioning goes, I really wish that I could choose both the rotation of the diameter line and the placement of the text, but the placement of the text automatically forces a particular orientation of the diameter arrows. -

hi,

you don't have to draw lines to measure from the center point to the steel plate edge. Start dimension, constrain the first point to the center of the circle and click, for the 2nd point, lock into a surface plane and move the curser to the edge of the steel plate and let the mouse pop over to a corner of the plate and click again. So drag your mouse around and orient the still dynamic dimension where you want it.

Advertisement