HP-Branded 3D Printers coming

-

Do you guys think this would be popular with architects? Its good to see a big name like HP behind this technology as they have the resources to mass market them. Pricing vague and tentative at something less than USD 15,000.

@unknownuser said:

Stratasys and HP Sign Definitive Agreement for Stratasys to Manufacture HP-Branded 3D Printers

MINNEAPOLIS, Jan 19, 2010 (BUSINESS WIRE) -- Stratasys, Inc. (Nasdaq: SSYS), the leading manufacturer of 3D printers and 3D production systems, today announced it has signed a definitive agreement with HP for Stratasys to manufacture an HP-branded 3D printer. Used by product designers and architects, Stratasys 3D printers create three-dimensional plastic models directly from 3D digital designs.

Full news release here, and more coverage from WIRED here.

-

-

Nice find, John...this is exciting because rapid prototyping is going to get way cheaper. It'll be interesting to see how this pans out.

-

yep, seriously cool technology,

I've been trying to sort out a set of rubies for 3D printing in stainless from Shapeways, I think SU is as close as any other package to do it all in a single package, only a few loose ends.

At the moment small bespoke (i.e. add your own name, tweek the size, etc) objects are do-able at a reasonable price with almost zero financial input from the designer, but I don't want to submit any until I can get from concept to printer all from SU... I know people already do it with architectural models, but with high res 3.2mm wire-form bicycle parts it's a little trickier

the wife does not understand...

-

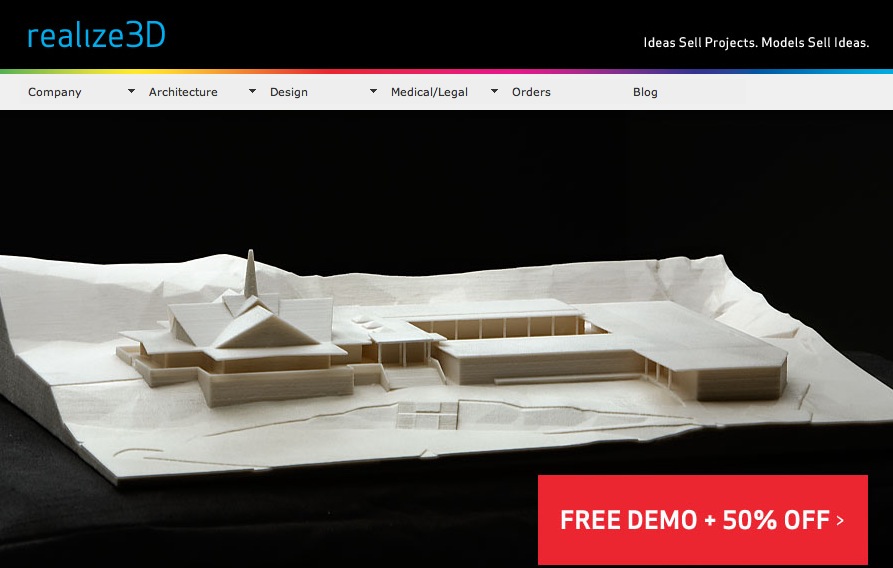

There is a company that has taken as advert slot on The Daily CatchUp, Realize3D http://realize3d.com/welcome_catchup.html

Don't know much about them but will try to get some further details and post same.

Mike

-

On a side note... on TED there's a talk about growing human organs - need a new bladder/artery we'll grow you one from a tiny bit of your old bladder/artery - just try to last 8 weeks... it's amazing - even custom sized or standard S/M/L/XL available... They culture/multiply the cells in petri dishes. Then they make a degradable mesh former and add cells on the inside/outside which grow into the new 'bit'. They even exercise it before it's transplanted so the muscles know what to do...

But back to the topic - complex organs have complex cross sections and many different cell types making them up.

It's at the experimental stage, BUT they have successfully used a HP[type] 3D printer with modified cartridges using different cell-solutions instead of ink-colors and degradable matrix rather than resin to '3D-print' a full sizedheart valve, building it up in thin slices - just like you do a model of a building or a new trainer ! The valve works and pumps !!!

So need a new ear ? - We'll take a good 3D MIR scan of the other ear and take a few cells from it, split them into the various sub-component cells, culture them to grow into enough within a few weeks, and then simply use the 3D model of the other ear [suitably mirrored !] with materials assigned to the various cell groupings, to print a fully functioning new ear within a few hours... It'll transplant onto you OK without any rejection as it is already 'you', and it should work just as well as the original - you might just see the 'join' though...

We live in amazing times - 3D printing of building models is fantastic but making a real working complex body-part basically in the same way is just mind-blowing...

See here http://www.ted.com/talks/anthony_atala_growing_organs_engineering_tissue.html

-

TIG,

you'll need to write an EarPlug.rb for the SU DIY'ers to make there own

-

I just spent several hours on http://www.shapeways.com/ ...wow, some cool stuff there. Does anybody know of any similar companies in the States(to get away from that international shipping/taxes/tariffs BS)? EDIT: I see realize3D is in the States.

@driven said:

I've been trying to sort out a set of rubies for 3D printing... but I don't want to submit any until I can get from concept to printer all from SU... I know people already do it with architectural models, but with high res 3.2mm wire-form bicycle parts it's a little trickier

I didn't quite understand what you are saying here...are you trying to get from SU to a format that Shapeways accepts?

-

@d12dozr said:

I didn't quite understand what you are saying here...are you trying to get from SU to a format that Shapeways accepts?

Firstly, everyone (that knows about it) in the states appears use Shapeways. They have a flat rate pricing system that's hard to be beat, have a wonder around the forum and you'll see even a some of USA 3D printshops are regular contributors/users.

For more conventional (none metal) presentation models the SU/CADSpan plugin and service are stateside. Shapeways offers something different, both from a product and a business model perspective.

The missing links are more to do with fine detail, accurate engineering product models that can be post processed to high tolerances. And that I can generate on a Mac.

so, (as TIG has shown up here) rubies like his VolumeCalculater's and some of the shrink wrap efforts need speed improvements to be viable for all in SU output,

one of the thing's I'm trying to get to work more efficiently is a letter stringer, so that a buyer can add there name to a curved tubular object, there's some image over at Chris's ComponantBender thread.

As far as getting them into Shapeways goes, there are file problems that require going into MeshLab or similar before export and I mentioned in another post that there is a Shapeways API available that would take you to the shop for pricing, ect... but it need pur(SU)ing by a ruby master..

I think a permanent 3D printing thread should be contemplated...

john

-

-

Gotcha, John. I agree Shapeways has a great selection of materials and an attractive business model, it would be great if they opened an office here in the US...

+1 on the permanent 3D printing thread.

I checked out realize3D...they say they can take straight SU models and can print in full color, but I couldn't find what material they use.

-

@tig said:

http://www.shapeways.com/tutorials/sketchup_3d_printing_export_to_stl_tutorial ?

Accutrans doesn't run on a Mac, and it's still having to go through at least two other apps to get a watertight mesh, I've used VolumeCalculator v2 to show me if it's watertight, but it can take 2-3 hrs on some of my sub-components on there own. I've been waiting for you to finish the RRby.. series before harassing you about possibilities for VC

-

@driven said:

@tig said:

http://www.shapeways.com/tutorials/sketchup_3d_printing_export_to_stl_tutorial ?

Accutrans doesn't run on a Mac, and it's still having to go through at least two other apps to get a watertight mesh, I've used VolumeCalculator v2 to show me if it's watertight, but it can take 2-3 hrs on some of my sub-components on there own. I've been waiting for you to finish the RRby.. series before harassing you about possibilities for VC

A better Volume Calc is still on the list but not in the top ten right now !

-

Can the error detection be split out on it's own for a fast watertight check?

-

@driven said:

Can the error detection be split out on it's own for a fast watertight check?

Probably... why not give me a few ideas in a PM... Outline what you want to do and I might even be able to make a separate Watertightness checker more easily that update VolumeCalc'...

-

@unknownuser said:

What file formats does Shapeways accept?

You can upload STL, VRML2/97, COLLADA or X3D files to Shapeways.John, can't you just use Collada(native SU export since ver 7.1)?

-

Another process to achieve the 'walk around the model' experience can be via the use of Holograms. I have mentioned a company doing this here, http://forums.sketchucation.com/viewtopic.php?f=179&t=25397

Mike

-

@d12dozr said:

@unknownuser said:

What file formats does Shapeways accept?

You can upload STL, VRML2/97, COLLADA or X3D files to Shapeways.John, can't you just use Collada(native SU export since ver 7.1)?

-

@d12dozr said:

@unknownuser said:

What file formats does Shapeways accept?

You can upload STL, VRML2/97, COLLADA or X3D files to Shapeways.John, can't you just use Collada(native SU export since ver 7.1)?

they still have some issues with their .dae translator, but I hope that's sorted by the time I can produce a watertight SU model (without external apps)

the other thing I'm attempting is an accurate SU material to represent printed stainless steels texture

any ideas on how to get a side layered texture not to wrap an organic shape, whilst ignoring the underlying mesh. as if printed?

-

My company has worked very closely with Stratasys itself. In fact my son James wrote what seems to be the world's best export filter directly from SU to stl (Sorry, can't share). The process is still very tedious for models of any complexity. Making sure the model is watertight is bad enough...especially on anything organic (it has to be a single external skin with no internal geometry whatsoever), but having to adapt a model that has been built in SU...not with stl particularly in mind...can be something of a nightmare, as the rationale between the two is often diametrically opposed. Efficient, low-poly curved surfaces in SU have to be subdivided and smoothed...or the 3D model ends up facetted. At the same time, much of the finer detail needs to be exaggerated because of the resolution of the printer.

Here's a shot of a printed model soldier. It looks okay...except for the fact that it's about six inches high and has still lost the end of the gun barrel. It's a print of this one.

I've also got a 13" model of the Chrysler building. It looks very impressive but it took me hours to adapt the SU file. Not only did I have to get rid of all the window frames and the detail on the Art Deco doors and gargoyles, but I had to run two or three (in some cases four) windows together into a single recessed rectangle in order for them to print at all. When scaled up, they needed to be recessed almost 6ft into the building.

The results are impressive...in a novelty kind of way. But I'd think again, for the moment, if you have an idea of simply printing out the equivalent of a SU clay render...only in 3D.

You can pre-check any stl file using the Redeye (sub-division of Stratasys) Discover STL viewer...it's free. This will allow you to see any faults in the model and also determine the minimum size you'll need to print in order not to lose existing essential detail. http://eu.redeyeondemand.com/DiscoverSTL.aspx

Advertisement