Wood choice

-

Another project I have on the books is to make a table for my deck. I just cannot bring myself to pay the outrageous amounts those things go for these days. And most of them are junk.

I have always been a fan of a tile tabletop and I have plenty leftover from when I tiled our bathrooms and kitchen. I would like to make it out of wood and top it off with the tile.

My question; what is the best wood and finish for an outside project?

Thanks for any help.

-

Eric, it depends upon the look you're after. You could go with teak and not apply a finish at all. With a little time and exposure the teak will turn a beautiful silver. You could use Ipe which is a common subsitute these days for teak and is used for building decks because it weathers well. You might look at cypress. It is very rot resistant--think of where it grows--and I think a pretty wood.

As far as finishes go, I would be looking at marine type finishes. There's a lot of choices depending upon what you want. There are several penetrating oil finishes that look nice without putting a skin on the wood. Otherwise you can look at spar and other varnishes. I think you'll want an oil based finish rather than a water based one, though.

If you want, I'll get a list of marine finshes that would be suitable.

-

@unknownuser said:

Another project I have on the books is to make a table for my deck. I just cannot bring myself to pay the outrageous amounts those things go for these days. And most of them are junk.

Here ya go: http://www.alibaba.com/product/arshnoor-11241961-10831132/Plywood_Cable_Reel.html

Cheap, available in different sizes, can be finished in a lot of different ways and versatile... Get a large one for the table and 4 or 5 for stools. Throw a seat cushion down on 'em and there ya go!

Cheers.

-

Eric, I think you can come up with a better design than cable spools. On the other hand, there's no legs to level.

-

Eric, I've found there are two tricks to having a successful outdoor project. Either spend the money on wood that weathers well (like the Ipe and Teak that Dave mentioned) or spend the time/money on a quality finish. Dave made some great suggestions with respect to both the wood and the finishes. Teak and Ipe, though beautiful, are pretty expensive woods. If the cost isn't a big concern, I would definitely lay the money down for some slabs of Teak. Just leave allowances, in cross grain situations, for expansion and contraction and let it go. It'll be the beautiful silver colour Dave mentioned in a season.

What ever wood you do choose, if quarter sawn wood is available, get it. Quarter sawn (versus flat sawn) tends not to change as much across its width as flat sawn wood.

If you want the bee's knees in weather-grade wood and finishes, think about boat. I know Dave has boat building as a hobby and could speak to this better than I could, but finishing teak with a spar finish is really, really pretty--but needs to be maintained every year.

-

Chalres makes some excellent points. Quartersawn lumber would be worthwhile because it is less likely to warp or cup. Teak is indeed very pretty with a good varnish on it. I didn't suggest it specifically because I'm thinking about the hatch rails on my Catalina 27. The previous owner didn't do the best job with the varish and it failed in a couple of spots and water got underneath it, got trapped and made a bit of a mess.

Beaware that teak is silicaceous and is hard on edge tools. Still, it's nice stuff if you can get it.

-

That is just it, where to get it? I would love Teak, Cypress or Ipe but I have no idea where to get it around here. I do go occasionally to my local sawmill to get poplar, cherry and oak. I guess I need to start asking around. I would imagine I could mail order some but that could get even more expensive.

However... that spool is looking rather inviting.

"Look honey, just like the dining table I had in college!" -

Check with some of the lumber suppliers used by the contractors in your area. I would imagine they would have the Cypress and Ipe although probably not the teak.

If you wish I'll check my contacts for you.

-

if you're planning on doing it in tile, you have to be more careful with expansion/contraction of the wood.. it's possible for it to crack the grout/mortar.. i'd apply the tile with a heavy duty const. adhesive such as liquid nails as it will be more flexible and create a stronger bond than mortar.. there's probably a rubbery type grout that may be better suited for outdoor tile on wood..

i'd also feel more comfortable if the tile was being applied to a plywood or sheet subsurface instead of dimensional lumber..

i see it as basically making the table top and then separately making a base.. two different projects so to speak.. if it's for an outdoor deck setting, i wouldn't put off the option of using standard pressure treated pine.. it's a lot cheaper, readily available meaning with a little effort, you can pick and choose.. nice #1 quartersawn pine can find it's way into the mix even at lowe's etc.. if you want to go that route, you might want to buy the stock at least a month or so in advance and let it dry/stablize.. (usually longer than that but it should be okay since it's going outside).. paint it or seal it and it's not an ugly wood plus it has some built in weather resistance..

as for finding the more elegant woods, google your area for 'solid hardwood' or 'alabama hardwood' etc.. weed through the flooring ads and you'll probably find a local distributor...

[edit] here's a wholesaler out of birmingham:

http://www.hardwoodweb.com/distribution/hia.cfmthey definitely have all you need.. maybe contact them and find a local retailer?

-

Thanks Dave, I will let you know if I need the contacts.

Jeff, thank you also. I was wondering if pressure treated would be alright but worry that after a couple seasons that I am rebuilding the table. I am not against painting it either. I have a nice color I used on the garage door to match our siding I could use. Of course I would get it in an oil base.

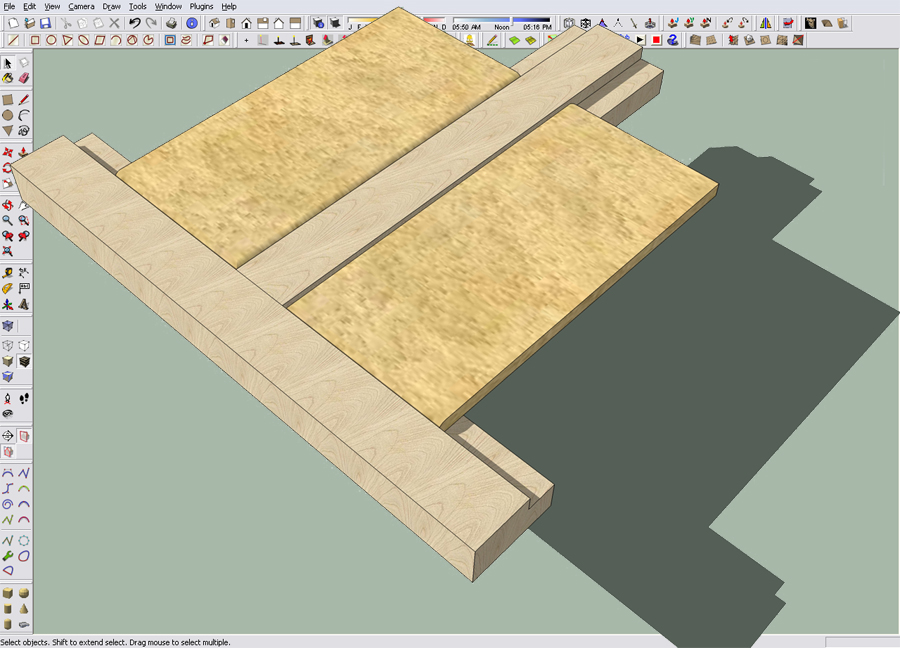

I had not planned on grouting the tile. I would like to make them floating, something like the attached image. That way I could maintain the wood easier.

-

@unknownuser said:

I had not planned on grouting the tile. I would like to make them floating, something like the attached image. That way I could maintain the wood easier.

ahh, ok.. that's a better way to do it. it will look nicer too - not as bulky as what i was picturing.

-

I wouldn't use pressure treated lumber for this. The chemical doesn't penetrate very deeply and everywhere you have a cut face there won't be be any treatment at all. There'll be a lot of cut faces with all those rabbets. If you can't get cypress and teak and ipe are out of range, you could go with western red cedar which is also common for building decks. Getting quarter sawn WRC is probably almost impossible. Cypress ought to be available in your area since it is a southern wood and frequently used for exterior trim and stuff on houses.

I think your idea looks good. How did you get the model to overlap the toolbars? I think I have an idea but...

-

What kind of glue and fasteners are best for outdoor furniture? I would imagine galvanized for the fasteners but I am not so sure on the glue.

-

stainless steel and a polyurethane based glue such as gorilla glue.. galvanized screws etc are sort of a hoax in that the coating wears off as you screw it in.. ceramic coated screws are another option and work better than galv.

-

Thanks. Sort of a Duah moment for me as I rebuilt my deck last summer using composite decking and STAINLESS STEEL screws

-

From my boat building experience I would use epoxy (not the five minute stuff) and either silicon bronze or stainless screws. Stainless are better than galvanized. As Jeff says, the galvanizing comes off too easily. It's too thin. With stainless you need to be careful, too, though. Stainless steel develops a sort of 'skin' that protects the metal from corrosion. The 'skin' will get damaged by the screwdriver. It will heal itself in the presence of oxygen but if you cover the screw with a plug or something, the healing won't take place. Then if you get moisture in there, the metal can corrode. Bronze is nice because it isn't affected by that. I think bronze oval head screws look nicer, too. Especially if you align the slots the same way.

Epoxy is a good choice for gluing because it is weather resistant and you can mix in fillers to make it gap filling if needed. It needs little clamping pressure. Once cured it can be sanded or machined and you can even drill it and tap the holes for machine screws.

If you have good faying surfaces, even Titebond III will work, though.

-

Eric, I spent the past couple of years living in Atlanta and I know Peach State Lumber carries cypress. Our old shop purchased lumber from there quite a lot and cypress was one of the woods, I believe. Western red cedar is a good choice, as Dave mentioned, and so is Redwood and Spanish Cedar. We've used all three in our shop for storm doors and screen doors with good success. It is definitely softer than Teak or Ipe but I'm sure less expensive. There is definitely lots of cypress to be had in the south. If you know a guy who knows a guy, go ahead and buy the old growth salvaged cypress--it's beautiful.

We use Titebond III for our exterior projects (we have a 8' x 8' door / sidelight assembly right now made out of oak that we've assembled with that product). Glues like gorilla glue are a pain to apply as have to wipe the mating surface with water and ---argh, just too many extra steps.

And please, please, please stay away from pressure treated lumber. Not only will it make you sick but the dust is gross and lacks the more polished look of real hard woods.

best,

Charlie -

hey Boo,

when it comes to the finish and adhesive for the wood i have had much success with the epoxy from West Systemsthe finish is extremely durable and easy to apply and when used as an adhesive there is no issue with squeeze out because the finish and glue are the same product.

of course Teak, Mahogany, Ipe, Cypress, Cedar, Maro Macho and a few other exotic hardwoods will all hold up well under the elements without any finish other than a yearly coat of some type of exterior grade penetrating oil.

if your local lumber supplier cannot locate and supply the wood you want than you might want to check with Woodweb and search the forums and databases for suppliers.

as for screws, stainless steel, Hot Dipped Galvy, or ceramic will all hold up fine but if they are going to be seen in the final project that SS is the best choice.

-

I appreciate that, thanks.

Advertisement