Router Bit Profiles in Sketchup

-

Newbie here. Trying to learn Sketchup thanks to Chiefwoodworker. I keep coming up with bright ideas for Sketchup. This is my latest: It would be nice if the major brand router bit manufacturers, such as Whiteside, Amana, etc. provided profiles of their router bits that could be loaded into Sketchup. I think they would need to be SKM files and accessed through the component browser, but not sure about that. For all I know this may already be available. Anyone have any choice thoughts on this? Seems like it would be a win/win/win situation. Sketchup model makers, woodworkers and the makers of router bits would all benefit. While wishing lets include the makers of shaper cutters.

Earl Creel -

been thinking about this for a wee while Earl, it's a good idea

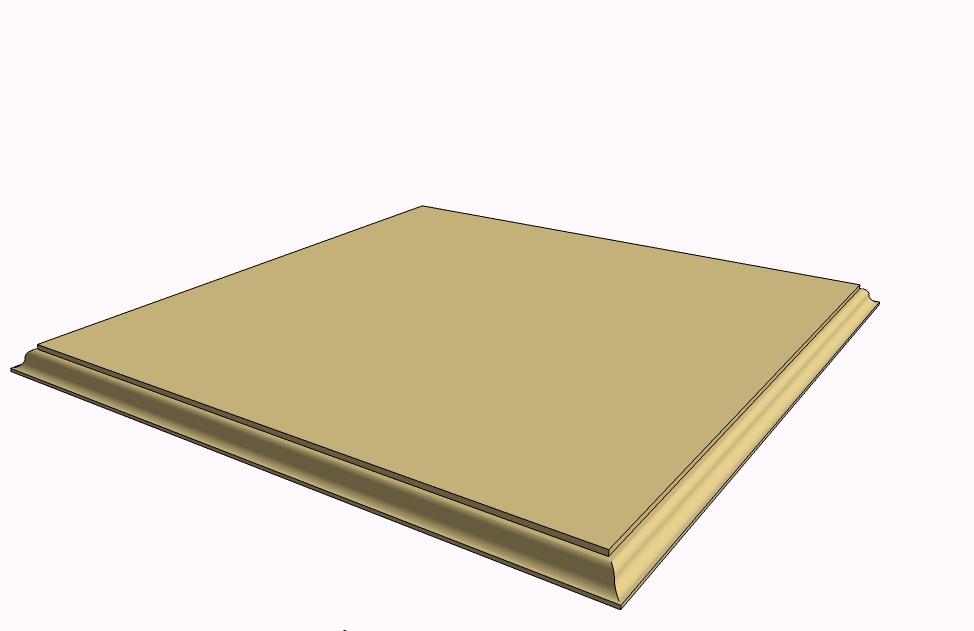

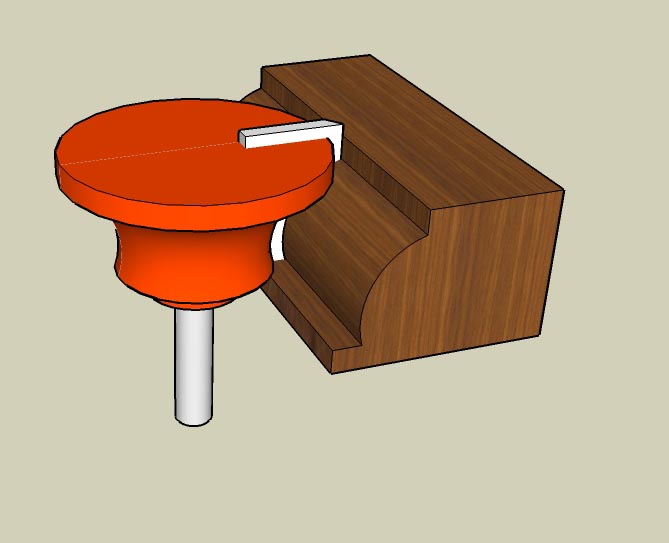

have attached a quickie i did

-

Actualy you can easily 'router' any shape you want along any and all edges using the 'follow me' tool.

Have a look at the attached file. -

Yep Gidon that is the process I want to be able to do, except I don't want to draw the profile, I want the bit makers to give all of their bit profiles to us in a file format that can be downloaded and placed into sketchup. Then we could select any available profile in the component browser by looking at the thumbnail and also identified by the manufactures part number. Clicking on the profile would insert the profile into the model and all that would be left to do is drag it into position, select the path and click it with the follow me tool. (no profile drawing required)

If after generating the edge profile you decide it don't look quite right for your model you could just backup and try another profile. Of course you had better like the profiles of bits you already have or you are going to run up your router bit bill.

Earl Creel -

While the manufacturers might not give us the profiles, there are profiles out there if you look.

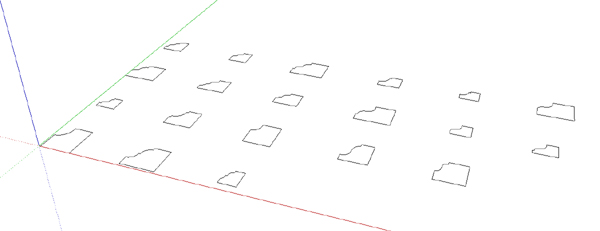

Here are some common ones in DXF format.

And a collection of bits from Magnate drawn up by Nick Webb.

Keep in mind your model is likely to get some bloat using these. You might want to simplify them a little before using them

-

RonS put some great molding profiles up on this site some time ago:

http://www.sketchucation.com/forums/scf/viewtopic.php?f=40&t=3001And a quick Google revealed this gem of a site:

http://www.woodworkersworkshop.com/cadfiles/cadsyms.htm

Looks like all of them are in dxf format which SU brings in just fine:

Like Dave said, they might be simplified a bit too. The arcs have many segments, at least this example. -

A collection like that would be nice, but I suspect that if there were such a library, I'd always need one of the ones which isn't available.

I usually import a copy of the profile as a *.jpg, then trace over it in SU and apply it to the edge I'm concerned with. That way, it's the profile I want with the level of detail I need.

I just checked on the 3d warehouse and if you search for " wood profiles " or " molding " or " moulding ", there are quite a few available there. This one http://sketchup.google.com/3dwarehouse/details?mid=7ba74e3e99d7ed7b3401db1f9405bd9e&prevstart=0 is nice.

Thanks,

-

For molding profiles there's also SF Victoriana and Stackis & Morrison. The latter has several SKP collections of interior casings; base moldings, door trim, etc. Osborne Wood Products offers DXF drawings of the table legs bun feet, columns, and other products they sell.

Lots of sources with just a bit of looking.

-

Thanks to all who have replied. I am getting a little smarter. It looks like some profiles are available in one format or another and with varying degrees of difficulty could be cleaned up and loaded into Sketchup. I am particularly interested in Whiteside router bits because I have some, others are available locally and all are available from Routerbits.com in about 3 days. (and the are arguably the best bits available)

I have sent an Email to Whiteside customer support hoping to connect with someone who understands Sketchup. My aim is to have them post on their website all their router bit profiles in a form and format that can be used in Sketchup without the need for additional work. Here is where I get in over my head because I don’t know exactly what the best format would be for seamless direct use by Sketchup. SKM files perhaps? Also don’t know if a Ruby plugin would be needed to handle the profiles. Maybe a new tool called “Profile Insert Tool “??? Anyone have ideas as to what would work best?

In the real world I often do not use the full profile of a bit. Adjusting bit depth and moving the router table fence can change the profile of the cut edge considerably. This same effect should be easy to model by simply adjusting where the profile is stuck down in the Sketchup model. Any part of the profile extending beyond the face to be extruded could just be erased.

Will post further on this subject if I make any headway with Whiteside. If Whiteside will do this other bit makers will probably follow.

Earl Creel

All married men fall into one of two groups, those who will admit they are hen-pecked and those who lie about it.

-

@earl creel said:

Newbie here. Trying to learn Sketchup

what an excellent way to improve your SU skills than to download their catalog and hand draw them into SU yourself. i did that exercises with different millwork and trim profiles and it helped my proficiency with SU.

-

SketchUp readily accepts dwg. files and easily integrates them into models.

-

I think the idea of drawing router bit profiles is interesting but I question the value of using precise router bit profiles for profiling the edges of parts in SketchUp. In the context of an entire piece of furniture or other woodworking project, you won't be able to see the difference between an ogee profile made with a Whiteside bit and one made by Stanley 45. It's just my opinion but I think insinuating the profile is enough and keeping it simple is the appropriate approach.

If you're going to make profiles, keep arcs very light. For example, 3 or 4 segments are probably enough for a roundover. There shouldn't be any difficulty in cleaning up and simplifying imported CAD files. They go pretty fast.

-

I agree with Dave. You have to consider two things:

- File size

- Resolution

The resolution at which you or your client will view the model is in most cases such that such details as the exact profile isn't an issue, and if you aren't carefull (and I speak here from personal experience) you'll find the highly faceted profiles all over your piece doubles and on occaision triples the file size.

-

Hi Folks,

I have profiled some bits as I use them in a design. The bit manufacturers give sufficient detail in their catalogs to draw 2D profiles that can be save as a component in your own library. Of course, it makes little sense to do this for bits you use once every three years, so it is the common ogee, round overs and coves that I tend to save.

-

So far no word from Whiteside. While waiting I have learned a little: Whiteside’s catalogue is available for down load from their website. It is a pdf document. However, using a screen capture utility you can select profiles in the catalogue right off of your screen and save the partial screen shot as a jpeg. The resulting file is small, something less than 10KB and SU seems to love jpeg files. Maybe this is as good as it gets. It is a procedure that makes cutter bit profile acquisition easy from any source that you can get to show up on your monitor.

The other thing I have learned is that to get the graphic image in your model is one thing but to get it traced into the model is a whole different can of worms. Hopefully when I get smarter it will turn out to be easy. Can one of you kind souls please point me to information that covers the very basics of tracing over a curved line in SU. (See attached skp.)

The screen capture utility I use is Printkey2000, for a long time it was freeware but the free version is now difficult to find. The website where you can buy the latest version for $20 is http://www.geocities.com/~gigaman . There are probably many other screen capture utilities that will work just fine but this is the only one I have experience with.

While wanting to learn how to trace correctly I still have a desire to make my computer do the work. Why can’t a simple curved line generated from an image file that appears on my monitor screen be captured, processed by my computer and put back on my monitor screen as connected line segments within SU ready to be pasted into my current model at the location of my choosing?

Earl Creel

-

Earl, perhaps you could explain how you got from profile to extrusion. I used the Arc tool and Line tool and had the profile traced in a few seconds. You'll note I reduced the arcs to 4 segments each. Extrude that profile and you'll see it doesn't look bad at all.

It looks to me as if you've used the Freehand tool. This isn't a particularly good choice for drawing radii. Don't over-analyze it. Just use Line and Arc and you'll be fine. And don't worry about being 100% accurate. No one will be able to tell when they look at the model anyway.

There's a program out there called WinTopo that will allow you to create a vector drawing from a raster image which you might find interesting. For router bit profiles, I think it is faster to trace the edge of the imported image using the basic tools.

-

Thanks Dave: Your profile sure looks better than mine. You are correct I did use the line and freehand tools. The troubles I had were:

- When trying to position the image on top of the stock face it would not slide smoothly into position but instead would only move in jumps and land a little off from where I wanted it to land. Would it work better to trace the profile out in a clear area, delete the image and then drag the drawn profile onto the drawn face? I will try this with your profile and see if it will position and stick without a fuss. …..Well it positioned okay but it did not stick. How do I get it to hook up with existing lines?

- When trying to trace with either the line tool or the freehand tool the cursor would not go where I wanted it to go. SU seems to have a mind of its own when it comes to placing points. By adjusting settings in window/model info the mouse action seemed to improve a little but not good enough to make tracing easy. Is there a combination of settings that will make mouse action smoother?

- Most of the time after tracing a profile the profile face would not form indicating the tracing was not continuous and hooked up at both ends. Or perhaps some of the profile got drawn above or below the face. Is there a way to restrain a string of segments to a face and force them to connect to an edge?

Will practice with the arc tool and see how that goes. Thanks again Dave for your help.

Earl Creel

-

Earl,

Just a guess but you have Enable Length Snapping checked. (Window>Model Info>Units) Uncheck it.

I would trace over the image of the profile. Actually, you could take an extrusion of the profile I drew and use Push/Pull on the vertical face opposite the ogee curve and pull it to make the width of the board. Pull down on the bottom to give it some additional thickness if you want.

Normally I would move the profile into place on a corner and use P/P or Follow Me to make the profile on the edge of the "board". when you grab the profile with the Move tool, grab it where it makes sense. For xample if the bottom right corner is to align with the bottom right corner of the board. grab the profile there.

When you are drawing, pay attention to the alignment of the edges so they stay on plane. Then the face should be filled.

Keep practicing. You'll get it.

Send me a private message with your e-mail. I'll send you something that'll help you out.

Advertisement