Hi all,

This is my first post. I have been scouring the forum for years to learn as much as I can from the professionals. First off I'd like to say thanks for sharing your knowledge and your time in helping me out : )

https://www.dropbox.com/s/2pdanuxwh8dpc1q/Help%20-%20Working%20File.skp?dl=0

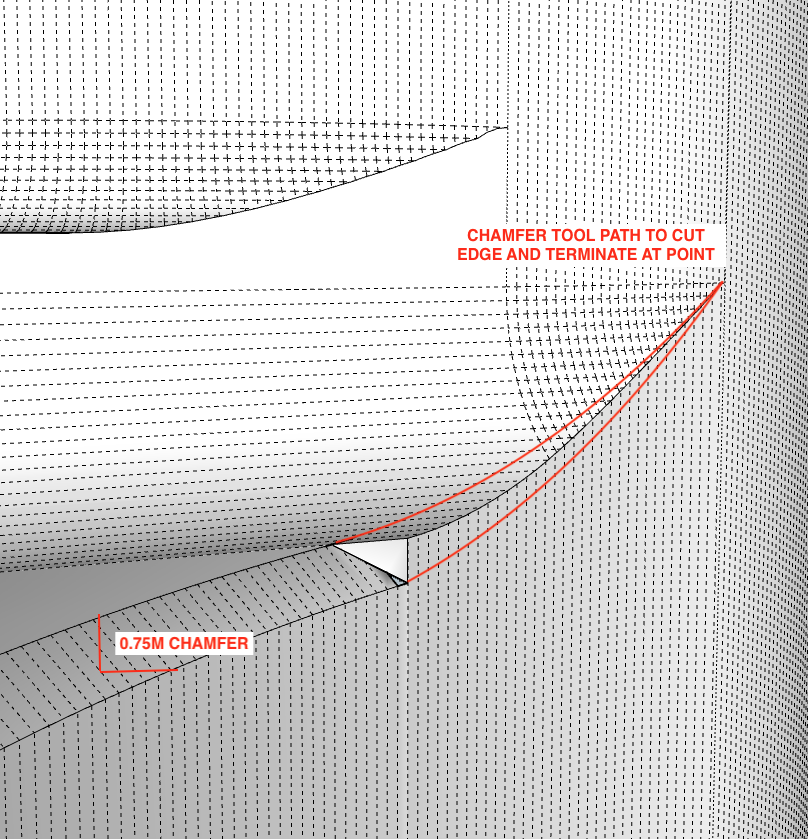

Linked is a model I am developing. I plan to prototype it with industrial 3D printing prior to final CNC milling. It is currently x100 scale. With the highest resolution (line sections) I can manage as I was informed by the printing company that their faceting tolerances are very tight.

My last operation was a solid subtraction to chamfer (rather a cove) inside the large bore. It took hours for SU to work through the operation but it was successful and I ended up with a solid group. Great! However, upon saving SU reported a problem. The "fix it" operation of course deleted some faces, leading me to my situation as noted in the subject line.

I have x6 surface boarder problems that are easily identifiable with Solid Inspector. I can't figure out how to close the mesh. I've encountered this before and have been successful correcting, but this time no such luck. I'm stumped and after hours of trying, the repair seems to be beyond me. I can get to the point where the faces return, but I end up with what appears to be a line over top a line. I can see this with hidden geometry. When I delete one line there is another hidden line. I delete again and attempt to close the mesh by connecting the intersection points, but the faces don't return.

I tried the operation over again by intersecting faces instead. This ended up really messy. For reasons I'm not sure of. After manually drawing in some line segments that SU didn't register. I couldn't seem to separate and remove the waste material in certain areas.

Perhaps someone may have time to look over the model for me? I am keen to learn from my mistakes. Any help and guidance is greatly appreciated.

Thanks again,

Stefan Mortveit