LOL I'm gettin' there! I work a little slower than you guys do. Plus I got sidetracked by research into fasteners, so your "doodle" is quite timely, and quite demonstrative, too. I understood what you meant, but that confirms my assumptions. Thanks.

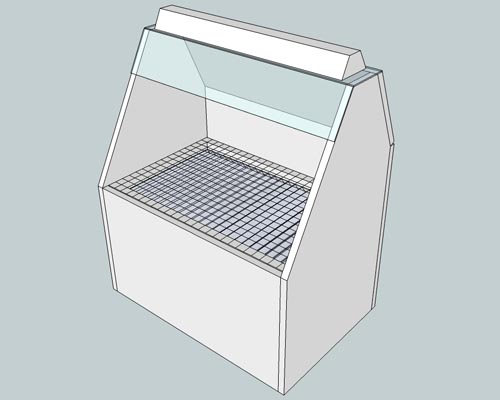

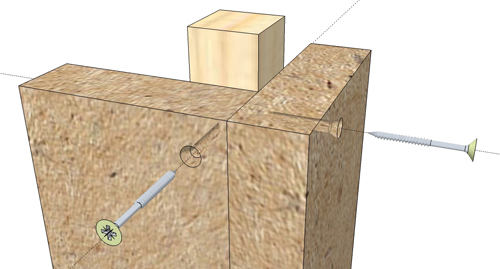

I'm wondering if you can help clear up a question I have, speaking of fasteners; I have read conflicting opinions about what type of fastener to use with MDF - there seems to be two (or more) schools of thought, with one camp saying "don't use wood screws, use Confirmat screws," and others saying "use drywall screws."

I know that drywall screws don't have the 'shear' strength, but would be the cheaper route to go, and I've read all over that guys say they are plenty strong for smaller projects. I have also read that the only proper way to secure MDF is to use the Confirmat bit and screws. What would you recommend for a 'cabinet' of this size? Also, won't I be screwing into the bracing? I thought I was trying to avoid screwing into the end grain like that. Or am I confused (It's possible  )?

)?

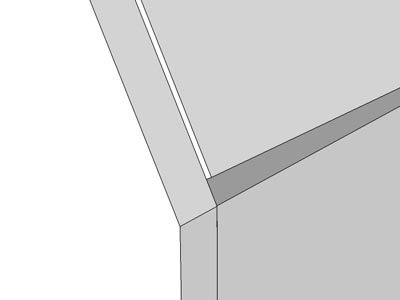

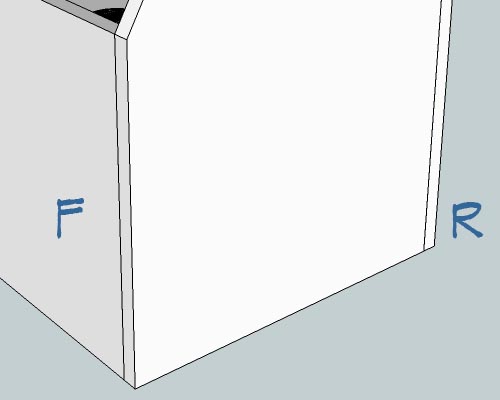

I know you guys will chastise me, but for my own personal build of this booth, I'm going to use 3/4" ply, as I have a bunch on hand, and can't justify (to myself, or the 'finance dept.' [read 'old lady']) the cost, no matter how small, of getting a sheet of MDF just for this.

I will however be producing the plans with the recommendation of MDF, so I'm not discounting what you guys are telling me, it's just that I wanted to use up the ply, and settled on this in order to do so. So I'll proceed as if I were building with MDF, in order to be accurate, but just be aware that I, personally, will be subbing plywood.

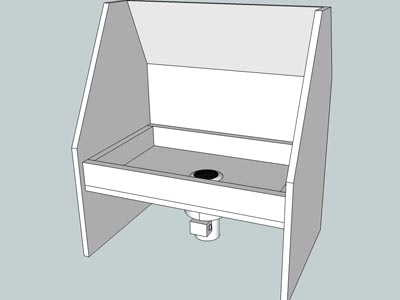

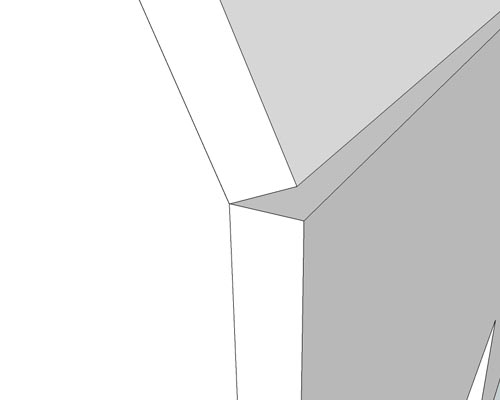

Regarding the overall design, there were just a couple of more things that I needed to work out, like adding some bracing below the booth bottom, as the blower motor will be hanging from it, and those motors aren't exactly light. So I wanted to make sure the bottom is secured strongly enough.

I'm also struggling with how to fasten the blower to the bottom of the booth. As it stands, the blower motor has two small sheet metal screws holding on the little circular screen, and I thought at first of just using longer screws to go through the booth bottom, through the spacer block, and into the housing.

But that seems a bit too flimsy to me, so I was thinking of some small diameter bolts instead, recess drilling the seat for the bolt head. I'd like to put the bolts in with the head side in the housing (and the nut in the recess in the booth bottom, but I don't think I can get them in that way, as the squirrel fan is in the way. Did I explain that clearly enough?

And also perhaps adding two more bolts for added stability. When the blower starts, it wants to twist, so I think I may need to strengthen it. Thoughts?

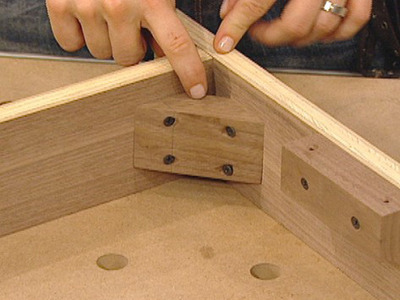

I put in the pole sockets and dowel as well - perfect. What a great idea! Thanks for that.

Ok, that's it for now. But I'll be plugging away at this tonight, so progress soon. And be patient with me - I'm a slowpoke.

)?

)?