Hi David,

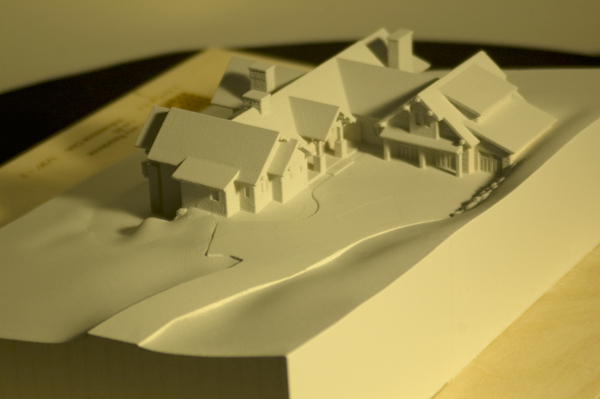

Sorry to hear your first experience with a z-corp machine left a bit to be desired. However, the level of detail on the model is very nice. Was the model for a healthcare clinic?

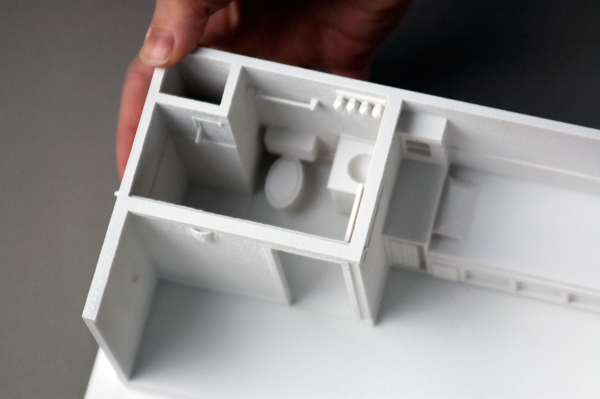

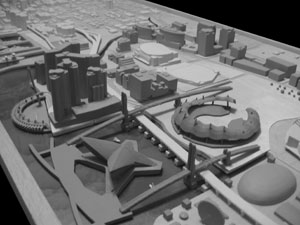

Seams can be tricky to work with...with a bit of work you can get pretty solid surfaces where the edges touch. Yet, they can take a bit of time. Here's a few photos of before and after. Also, thought you might get a kick out of this small bathroom and room layout we did for a client that builds temporary housing plans using SketchUp. Amazing what can come out of 3D Warehouse and eventually a 3d printer.

How did the model work for your client meeting?

Jake

Sweet Onion Creations