Edge Length Attribute

-

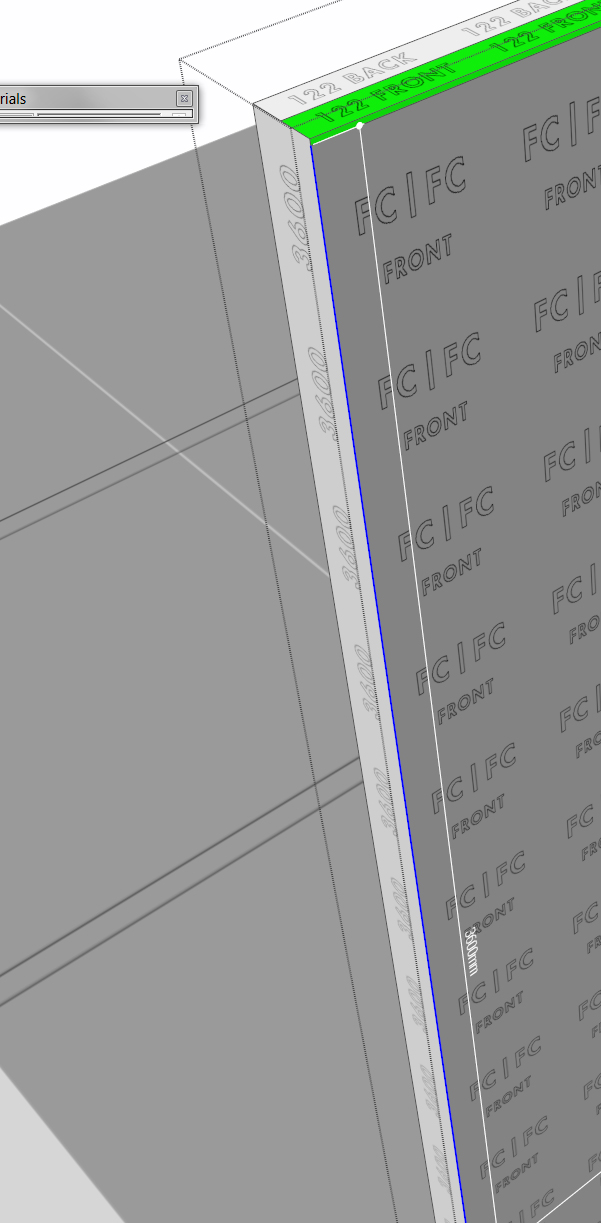

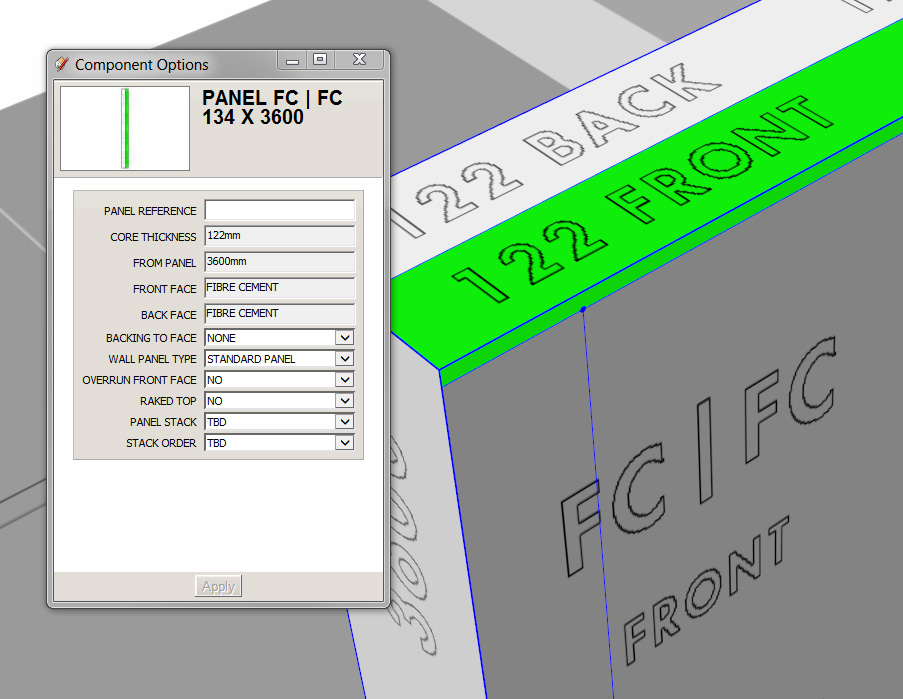

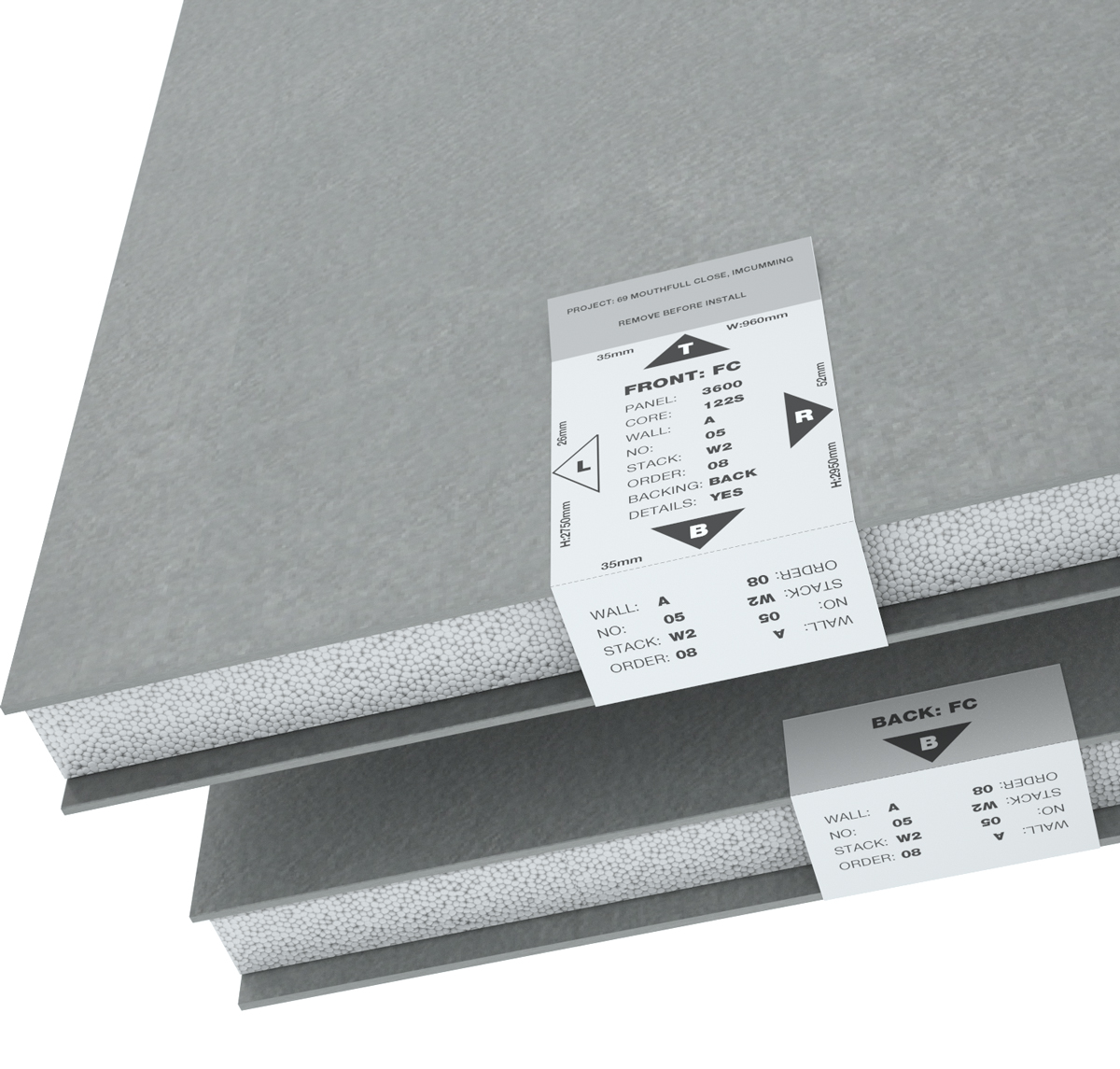

Hey chappies, I'm developing a system for SIP panels that will push the data to a sticker to manufacturing in lieu of producing a fully detailed drawing set. The actual finished panel finishes 10mm off the floor and ceiling and 1mm from each centre of jointing. The system works fastest if the component is set to the overall floor to ceiling lines and centre of joint to centre of joint.

In addition, around half of the panels are raked at the top to meet the raked ceiling. All this then creates a problem in gathering the left and right panel dimensions.

Given this is actually my first play with DC's I'm at my limits, and wondering if it is at all possible to get direct feedback of an edge length (or selected dimension)?

-

I would say its possible, would the panels have side cutouts for openings?

-

@pcmoor said:

I would say its possible, would the panels have side cutouts for openings?

Mate 99% of panels would be of standard or modified width and/or raked top, any breaks to these standards would be subject to a detailed drawing (hence the included option on the label for "Details: Yes/No" which would cause production to reference drawings.

-

here is a panel DC within a working file that can be scaled or fixed and set to different pitches and returns the dimensions in the option dialog

Use the fixed position (drop down option) to start with, then use the scale position to match the next panel (direction via another dropdown)

(its not fully tested, so if there's something not quite right...its fixable)

I can help you if you private message your DCwith regards the work flow, the report writer can transfer the required data to excel. Excel can hold the formatted label, exactly as you have shown with named cells in the data positions. An VBA routine can be made to transfer the data sheet from Sketchup to the labels required, in that Copies be made in excel and filled out to suit each component that exists on the report

I am well acquainted with excel and VBA

P.S. most likely would build this DC differently, however it does give you an idea to how to achieve your goal

-

@pcmoor said:

here is a panel DC within a working file that can be scaled or fixed and set to different pitches and returns the dimensions in the option dialog

Use the fixed position (drop down option) to start with, then use the scale position to match the next panel (direction via another dropdown)

(its not fully tested, so if there's something not quite right...its fixable)

I can help you if you private message your DCwith regards the work flow, the report writer can transfer the required data to excel. Excel can hold the formatted label, exactly as you have shown with named cells in the data positions. An VBA routine can be made to transfer the data sheet from Sketchup to the labels required, in that Copies be made in excel and filled out to suit each component that exists on the report

I am well acquainted with excel and VBA

P.S. most likely would build this DC differently, however it does give you an idea to how to achieve your goal

Thanks so much mate, and I will likely seek your employ to help out with this! I did workout how to easily apply the data to the sticker through a simple word doc using mail merge. Though totally open for a more streamlined option.

I'd certainly like to see how the DC can be better constructed and function. We didn't plan on having it scaleable as we were planning to stick with blocks made of standard dimension panels so we can see exactly what is constituting the makeup and switch out say a 2.7m panel for a 3.0m panel when they exceed the height.

I've now got to jump in and upgrade my SU license, as I haven't since I left the test team after 10years and by doing so I got the demand to buy a whole new license, rather than just move to the maintenance program! It just went against my grain!

Advertisement