Medeek Wall Plugin

-

Has anyone ever seen or tried these type of studs?

-

Version 1.1.1 - 06.19.2019

- Corrected the code for raising and logging exceptions.

-

Version 1.1.2 - 06.25.2019

- Fixed an HTML/javascript bug with the wall edit menu (specific to Internet Explorer).

- Fixed an HTML/javascript bug in the General tab of the Global Settings (specific to Internet Explorer).

These two fixes were prompted by problems being encountered by users of SketchUp 2015. I haven't quite decided yet but I will probably end support for SU 2015 and 2016 in the very near future as I have already done with the Truss plugin. At some point the effort to maintain compatibility with older versions of SketchUp is no longer feasible or profitable.

If you are a registered or even trial version user of the plugin and still using SU 2015 or SU 2016, please contact me so that I can get a better feel for how many users are still requiring this compatibility.

-

Excellent live modeling session by Aaron this afternoon:

After spending quite some time modeling this very simple structure it quickly becomes clear to me why extensions are so important.

I am hoping to get the gable and shed walls out shortly to close that gap.

-

As some of you are aware the Wall plugin includes a number of connectors and hardware, primarily Simpson Strong-Tie but a few others vendors as well. The full list is available here:

Medeek Design Inc. - Medeek Wall Plugin Vendors

Medeek Design Inc. - Medeek Wall Plugin Vendors

(design.medeek.com)

Mitek also provides a comparable line of hardware with their USP Structural Connectors. I'm considering adding in the equivalent product lines from Mitek and then allowing the user to specify in the Global Settings which vendor they prefer so that the menus populate with the appropriate vendor's products and thereby give the user more options and control over their hardware choices.

-

SketchUp Essentials latest video on the mdkBIM suite:

-

Good for you! That's like having some advertising and training done for you as well. as seeing how others experience the plugins.

-

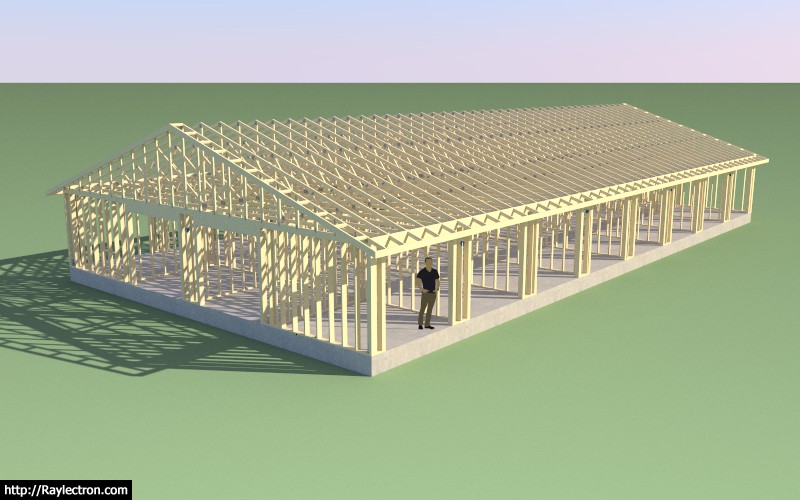

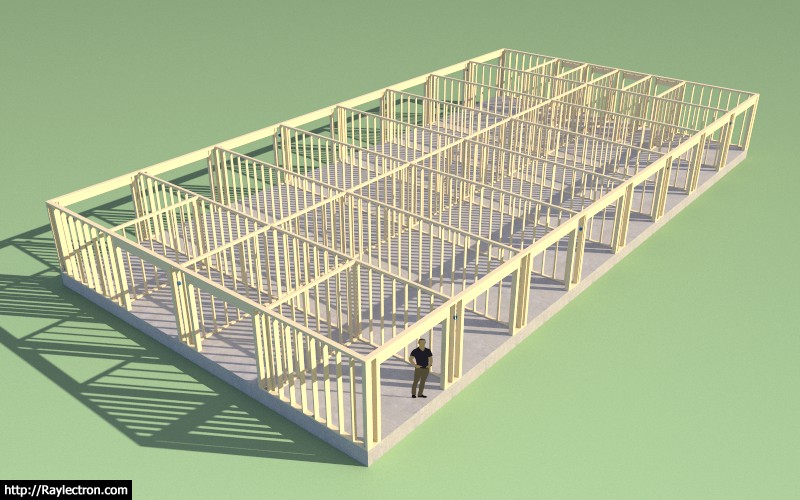

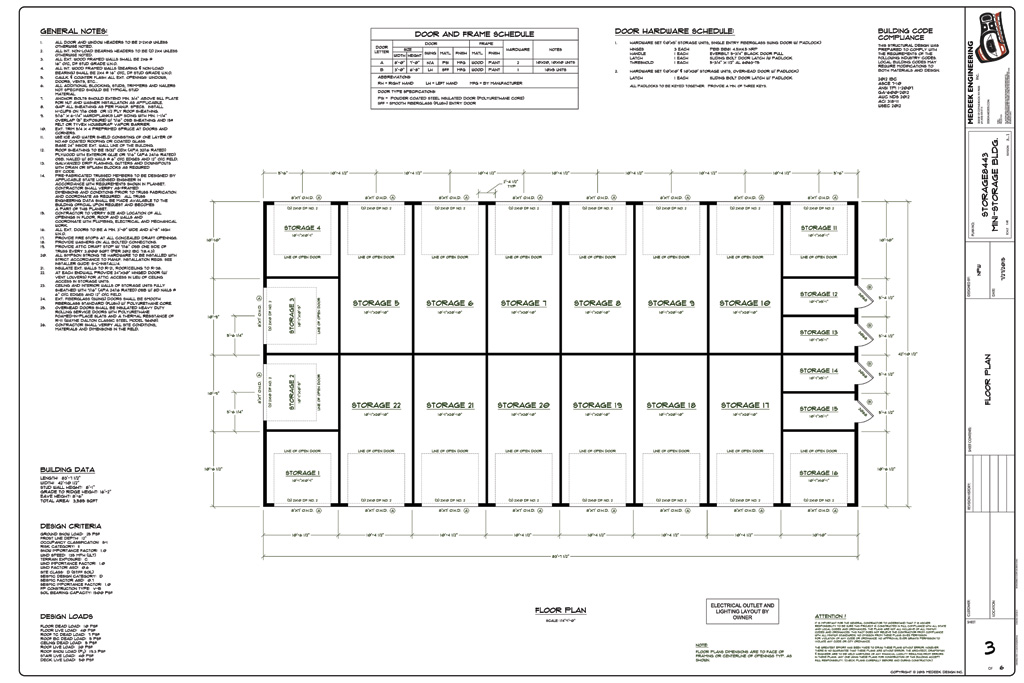

This particular design for a storage unit was originally created by me about four years ago for a local client here in Western Washington. I had another purchase of this planset from my website and the customer requested that I also provide the 3D model so I thought this might be a good opportunity to test out the plugins and see what difficulties I would encounter with a fairly simple but large model:

Framing:

Wall Framing and Foundation:

The floor plan (originally drawn in AutoCad):

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

This planset can be purchased here: http://design.medeek.com/plans/search.pl

Overall the process of creating the model went quite smoothly, I was pleasantly surprised. However I did note a few things:

1.) When you have a large wall and are putting an excessive amount of doors or windows into it the regen time starts to become noticeable. Not sure what the fix is here but I will give it some thought.

2.) With extremely large truss assemblies it may be advantageous to turn off the metal connector plates, the model gets a bit heavy and regen times are also affected.

3.) I need to add in more light fixtures (ie. external wall packs)

4.) There is currently no way to add a vent or window into a gable truss. This had to be done manually.

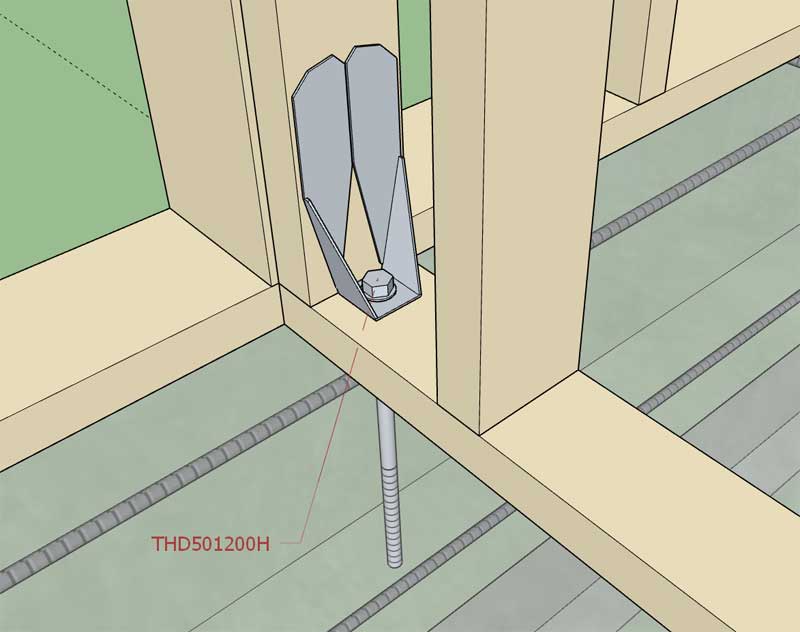

5.) The Simpson holdown DTT2Z was not being properly rotated, additionally I needed to utilized a Titen HD bolt in this model, I will address that this evening and release and update of the Wall plugin shortly.

6.) Anchor bolts typically need to be manually moved around and deleted. It would be nice to figure out a way for the plugin to preserve the manual manipulations even with a regen when the assembly is edited.

7.) I don't have a way to deal with two wall intersecting each other in a "CROSS", in the model I simply had them pass through each other. I will need to give this some further thought.

8.) I don't like the way I am creating/managing the components for slab reinforcement (mesh or rebar). I will need to change this up slightly. It works but performance suffers on large SOG foundations.

9.) Obviously I need to spend some time further integrating the estimating module, that would be really nice for generating a materials list.

10.) The parametrics of all of the plugins is really nice and to be honest, essential.

11.) I manually copied over some more gutter downspouts since I need more for this long gutter run. By adding CUSTOM into the instance name I am able to maintain these additional downspouts even with a regen of the truss assembly.

-

Version 1.1.3 - 09.23.2019

- Fixed a bug with the placement of Simpson's DTT2Z holdown and replaced included component with a low poly version.

- Added the option for Titen HD holdown anchor bolts: THD50500H, THD50600H, THD50800H, THD501200H, THD501400H, THD501500H.

-

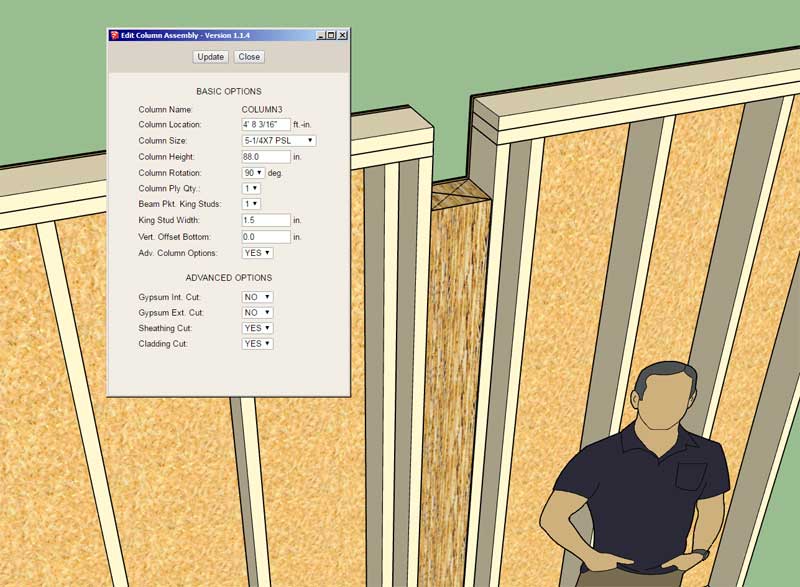

Version 1.1.4 - 09.28.2019

- Fixed a critical performance bug that affects all the modules within the extension.

*** CRITICAL PERFORMANCE UPDATE ***

If you are noticing a slowdown of the plugin performance after multiple edits to a wall assembly, this fix will resolve that issue. This issue affects all previous versions of the plugin.

-

The question "Can I manually edit my wall assemblies?", seems to come up quite often.

***** Important Information *****

The parametrics (editing) with regards to the plugin(s) require that when you edit any wall assembly, roof assembly, foundation assembly etc... it regenerates the geometry from the parameters stored for that assembly.

If you are going to manually edit an assembly just be sure not to regen it, by editing it or adding windows, doors etc... after you have done any manual edits. When you edit an assembly it essentially removes the existing geometry created by the plugin and redraws it. If you have altered the geometry created by the plugin it will also remove any of those manual edits.

You can effectively lock an assembly by removing the instance name (or replace it with something else). When you remove the key words in the assembly instance name the plugin(s) no longer recognizes the assemblies as something they can edit and hence they become "locked" for editing.

You can also unlock a valid assembly (provided it still has its attribute library) by putting the keywords back into an instance name. You will notice that each type of assembly has specific keywords utilized in its instance name.

The problem with manual editing is that, yes you can do it, but the plugins have no way of knowing what changes you have done to the assembly and when it goes to rebuild/regen the only information it has is the parameters stored in its attribute library (database) for that assembly. If you explode the group that contains the assembly the attribute library for that group (assembly) is deleted and even if you were to group the assembly back together the attribute library will no longer be present and hence the assembly is no longer a parametric Medeek assembly.

If you want to include custom components or groups within your assemblies (wall, truss etc...) and you want those "additional" geometric objects retained after a rebuild then you can accomplish this by including the keyword "CUSTOM" or "custom" within the sub-group or components instance name.

Also note that any non-grouped geometry (ie. edges and faces) will also be retained within the assembly by default.

In fact, this is exactly how the electrical plugin works in concert with the Wall and Truss plugins. All of the electrical groups within your wall panels, utilize a special key word in their instance names. This allows them to be retained within the larger assemblies.

There is a method to my madness.

-

Gable Wall Workaround:

A quick tutorial on how to manually edit a wall with the Trim tool to create a balloon framed gable wall.

-

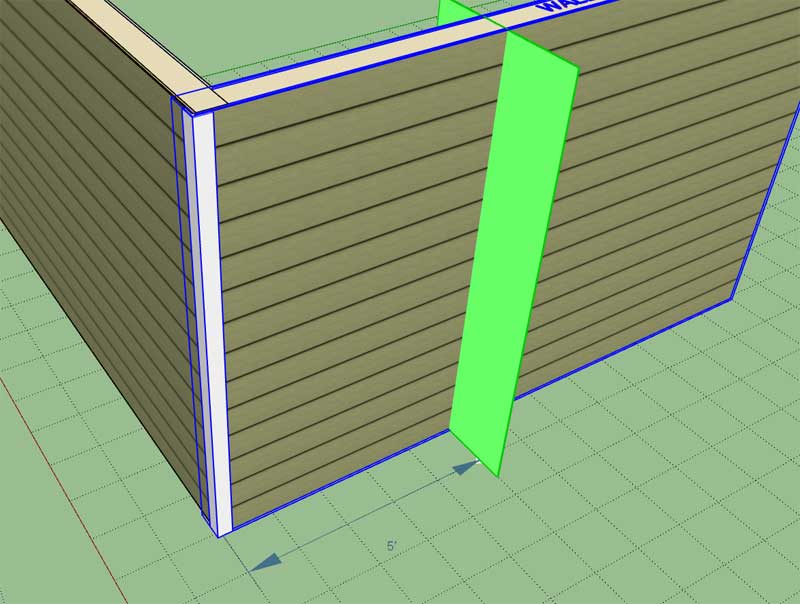

Version 1.1.5 - 11.27.2019

- Added a rotation parameter for in-wall columns.

Previously I was listing two sizes in order to get the rotated version (ie. 2x6 and 6x2) of a column size, however this proved to be a clunky and a non-scalable solution. This update rectifies this limitation.

-

Version 1.1.6 - 12.08.2019

- Improved the stability and execution speed of the wall edit menu and the window edit menu.

This improvement is courtesy of my recent work on the complex roof module of the truss plugin. I've improved the speed and stability of my algorithms for transferring data between the ruby code and the javascript. I will now need to update every other HTML menu found with the wall plugin and eventually within all of the plugins.

The wall edit menu contains the most parameters and hence its stability will be improved significantly by this code change, that is why I addressed it first. Other edit menus include: doors, garage doors, stairs, beams, etc...

-

Version 1.1.6c - 12.11.2019

- Updated the garage door edit menu and the door edit menu.

- Added standard sizes of LVL headers (1-3/4") to the built-in header library: 7-1/4, 9-1/4, 11-1/4, 11-7/8, 14, 16.

Within the global settings under the custom header settings the user can easily setup additional LVL headers. I setup these standard sizes for convenience, however any size (width and depth) may be defined.

-

Version 1.1.7 - 12.21.2019

- Enabled the "Wall Split" tool within the Medeek Wall Tools toolbar.

I will release a tutorial video explaining the use of this new tool and what circumstances would typically require its use.

(Click GIF to view animation)

-

Tutorial 9 - Split Wall Tool (6:36 min.)

-

You mean like this? (click to view animation)

View model here:

3D Warehouse

3D Warehouse is a website of searchable, pre-made 3D models that works seamlessly with SketchUp.

(3dwarehouse.sketchup.com)

-

Version 1.1.7b - 12.25.2019

- Enabled temporary (construction) dimensions for the wall split tool.

- Added a vertical offset to the holdown symbol(s) to eliminate Z-fighting with the wall panel top plate.

-

Something that I have had on the to-do list for quite a while but have avoided it due to the many permutations and pitfalls: Stacked Windows

I have some additional testing to do, but so long as the windows line up (same x-position along wall) and they are the same width (as shown) then the algorithm seems to be successful.

The real problems arise when the windows partially overlap, or even if they are aligned but the windows widths are different. Those type of scenarios create all kinds of framing permutations which then becomes a real can of worms for the logic. I may eventually tackle it but for now I’m going to make some simple assumptions, so that I don’t become too bogged down with this problem.

Advertisement